Description

Introduction:

The CanNeed-Chip-A200 is a semi-automatic machine for counting components on 7-inch to 15-inch reels. Users can manually load up to four reels at a time into the counter. The system verifies the part number, utilizes X-ray imaging for scanning and counting, automatically connects to the MES system for deduction, and automatically prints counting labels, providing a convenient and efficient solution.

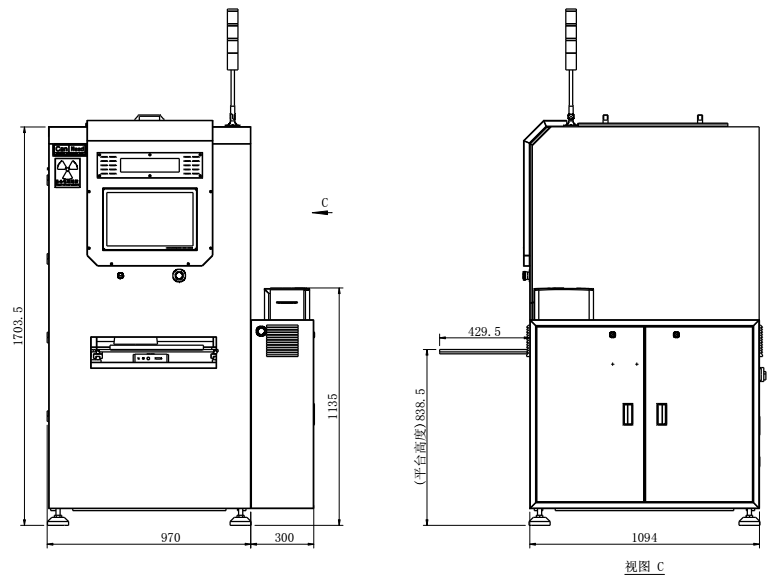

Equipment Dimension Diagram

Technical Parameters

| Category | Parameter | Specification / Value |

| Detection Parameters | Scanning Size | 180mm – 380mm |

| Speed | ≤10 seconds (for 4x 7-inch reels; single reel for other sizes) | |

| Component Size | Minimum CHIP size 0201 / 01005 | |

| Reel Height Acceptance | 8mm – 45mm | |

| Counting Accuracy | ≥ 99.7% | |

| X-Ray Source | Tube Max Voltage | 100 kV |

| Tube Max Current | 4.5 mA | |

| Tube Max Power | 150 W | |

| Flat Panel Detector | Detector Type | Amorphous Silicon Flat Panel Detector |

| Pixel Size | 0.138mm | |

| Machine Status | Loading Method | Manual Loading |

| Unloading Method | Manual Unloading | |

| Barcode Scanning Method | Automatic CCD Scanner (Optional) | |

| Label Application | Manual Application (with misplacement prevention) | |

| Label Printing | Auto-connect to REP/MES systems, automatic barcode printing | |

| Equipment Orientation | Front Load / Front Unload | |

| Other | Machine Dimensions | 1330mm (L) x 1480mm (W) x 1850mm (H) |

| Net Weight | 1210 KG | |

| Power Supply | 220VAC ±10%, 50/60Hz | |

| Power Consumption | 1.5 KW | |

| Air Pressure | 0.5 MPa | |

| Operating Temperature | < 40°C | |

| Relative Humidity | Standard 70% @ 32°C | |

| Safety |

|