|

| |

Product Classification : Can Making----Double Seam Inspection

|

| Total page:1

Current page:1 Total records:21 |

First | Previous | Next | Last

|

|

|

Seam-X-On-line X-Ray Automatic Seam Scanner(Non-destructive)

|

|

The CanNeed “Seam-X-On-Line X-Ray Automatic Seam Scanner” adopts non-destructive measurement method to measure the seam quality, suitable for measuring the aluminum cans, steel cans , aluminum-iron composite cans and etc. It’s applicable for online in producing department. It’s a non-destructive, cost saving, accurate measurement and automatic equipment which can be installed on the production line to improve the sampling frequency.

|

|

|

Seam-X-Line X-Ray Automatic Seam Scanner (Non-destructive)

|

|

Seam-X®-Line Automatic Seam Scanner adopts non-destructive measurement method to measure the seam quality, suitable for measuring the aluminium cans, steel cans , aluminium-iron composite cans and etc. If configured with the conveyor, it can achieve automatic sampling from the production line. It's applicable for laboratory or producing department.

|

|

|

SeamSight®-C Full Automatic Seam Monitor

|

|

The SeamSight® system is equipped with the new seam measuring software SeamSight® Professional Software. Which will do the line positioning automatically and the measurement to be finished within 1 second!

Use the CanNeed SPC data collection system, The actual seam thickness, actual countersink, etc., can be transferred to the computer automatically.

The software also adopted the data base management system, all the measurement data will be restored in the system data base, so that to enhance the software performance and more convenience in data management. The result statistic and result chart has been added in the data base screen for overview and comparison. Meanwhile, the measurement screen has been optimized for a vivid result display.

With CanNeed Automatic Seam Sight® Monitor, press only one key “Auto Measure” to do the line positioning automatically and the measurement to be finished within 1 second! It can measure the seam dimension automatically, efficiently, simply and also avoid operator mistake. Use the CanNeed SPC data collection system (CSG-200 countersink gauge & STG-200D seam thickness gauge), the actual seam thickness, actual countersink, etc., can be transferred to the computer automatically. Such data can generate a report together with other data, improving the process.

|

|

|

CSS-1000 Anti-noise Seam Saw

|

The CanNeed “CSS-1000 Anti-noise Seam Saw” is provided with an anti-noise design and a special guide

for 2-and 3-piece cans with 65mm dia, such as beer cans and 209 cans. The cutting process is so precise, quick, safe and convenient to ensure precise cutting effects without distorting the cans. The seam image on Canneed series Seam Sight TM automatic seam measuring systems gets thereby every clear and improves measurement speed and reliability.

|

|

|

CanNeed-CSS-2000 Seam Saw

|

CanNeed-CSS-2000 Seam Saw is a special unit to cut the cans with double seam for inspection.

Sample moving platform is assembled on linear rail with precise cutting effect to ensure that cutting image is very clear when inspecting the seam quality with CanNeed Seam Sight automatic seam monitor.

Linear rail for can moving is installed to make the perfect linear cutting. Configured with extreme hard blade, it is durable and enables the cutting clear without burrs.

|

|

|

CanNeed-CSS-100B Anti-noise Seam Saw

|

|

CanNeed-CSS-100B Anti-noise seam saw is provided with an anti-noise design and a special guide for 2- and 3-piece cans (65 mm dia.). Special seam circular saw with double cut for can double seam inspections. The CanNeed -CSS-100B was specially designed for 2 and 3-piece cans.

The nitrated blades achieve together with the speed of approx. 1.000 r/min. a very plain cut surface. The seam image on VSM 6A Automatic Seam Computer (Video Seam Monitors), and automatic seam measuring systems gets thereby very clear and improves measurement speed and reliability.

|

|

|

CanNeed-CSS-300 Seam Saw

|

|

CanNeed-CSS-300 Seam saw is a special seam circular saw with double cut for double seam inspections.

The CanNeed -CSS-300 has specially designed for the irregular shaped cans, like rectangle cans, oval cans, etc. Also aerosol-cans can also be sawed with the saw. The nitrated blades achieve together with the speed of approx. 1.000 r/min. so that comes a very plain cut surface. The seam Image on the CanNeed series of Automatic Seam Monitors gets thereby very clear and improves measurement speed and reliability.

|

|

|

STG-200-D Seam thickness gauge(digital)

|

|

The CanNeed STG-200-D Seam thickness gauge can be used to measure Seam thickness.

With measure angle compensation. The center mesure point can be adjusted.

Cans can be auto- positoned in the center easily during measuring .

With the Mitutoyo 0.01mm Resolution Digital Indicator.

If you purchase the adapter and cable, the instrument can communicate with a computer.

|

|

|

CanNeed-CSG-200 Countersink Gauge (Digital)

|

|

The CanNeed-CSG-200 Countersink Gauge (digital) is a Digital gauge for measuring Countersink depth parameters (the depth of beader of can). With the Mitutoyo 0.01mm Resolution Digital Indicator.

The gauge can be connected to a computer or SPC system via the adapter and cable, so that to avoid the manual recording and personal error. The gauge can also combine with Canneed Seam Monitors and import the measurement data into computer.

|

|

|

CanNeed-STR-100 Seam Stripper

|

|

The CanNeed-STR-100 Can Cover Trim Stripper is designed to quickly and accurately cut can cover trim in place for inspection of cover hook wrinkles and tightness. The CanNeed-STR-100 is also used for boiling tests where a large number of sample cans need to be cut away from the lid to observe the inside of the can.

|

|

|

SCG-200 Seamer clearance Gauge

|

|

The CanNeed SCG-200 Seamer clearance Gauge, a quick and accurate way to set up seamers.

To measure the roll height off the chuck and the lateral distance between the roll and chuck.

|

|

|

CanNeed-CAN-1050D Digital Can Closing Force Gauge

|

|

CanNeed-CAN-1050D Can Closing Force Gauge is for measuring the force of seaming head of the seaming machine. By using CanNeed-CAN-1050d, producers can avoid product defects caused by over plating: sharp edge, seam breakage, body deformation, body hook overlength, over large countersink and so on. In the meantime, producers can also avoid product defects caused by too small pallet lift force: slippery cans, too short hook and so on.

|

|

|

CAN-1050 Can Closing Force Gages

|

|

The CanNeed CAN-1050 Can Closing Force Gages can lower scrap rates and set up time. you can quickly and easily job-set multiple-station canning machines. These Gauges come with and adjustable self-loading micrometer dial, calibrated in thousandths. This means you may accurately deflect spring-loaded can wear plates to any desired dimension.

|

|

|

CanNeed-CAN-10774 Planer and Shaper Pin Height Gauge

|

|

CanNeed-CAN-10774 The Pin Height Gauge is commonly used in the initial setup of the seamer to ensure double seaming

performance and air removal.

All working surfaces are hardened and accurately ground.

|

|

|

RPG-100 Roll profile Gauge

|

|

The CanNeed RPG-100 is able to scan profiles of seaming Rolls and Chucks (or other tooling - including carbide and ceramic tools) easily and quickly. The system can be used for acceptance testing for new seaming rolls or chucks, for quality assurance purposes and for stress analysis. Monitor tooling wear to replace rolls and chucks only when they need to be replaced

|

|

|

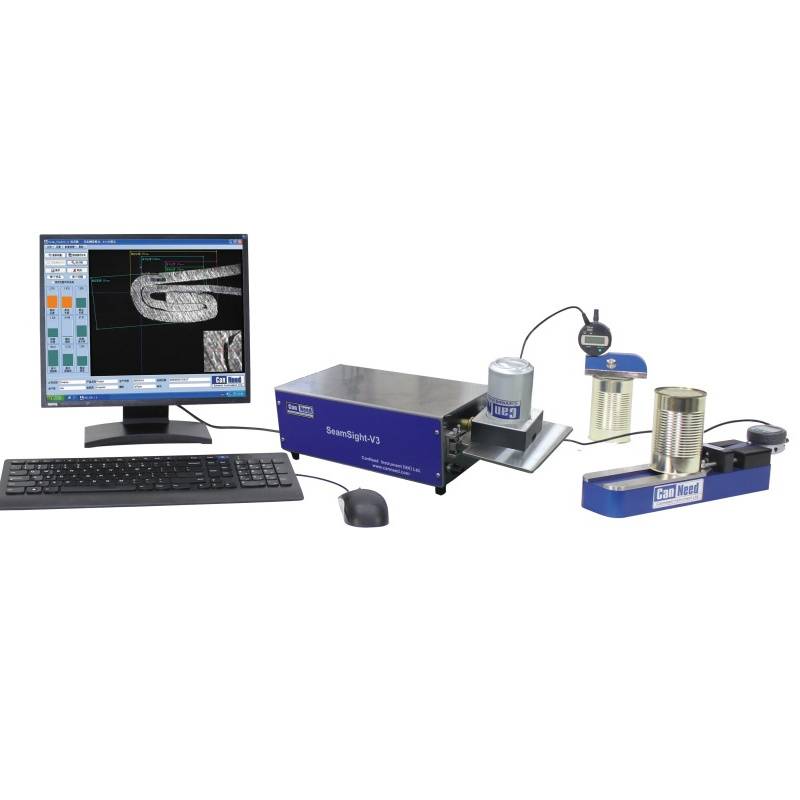

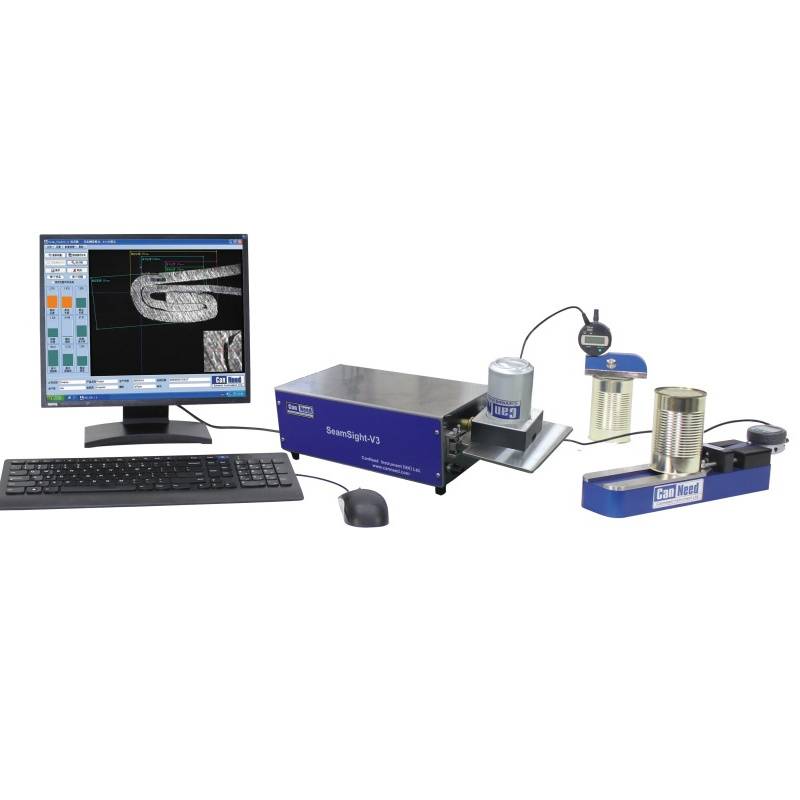

SeamSight®-V3 Full Automatic Seam Monitor

|

|

The CanNeed Seam Sight® professional seam measuring software will do the line positioning automatically and the measurement to be finished within 1 second! The software also adopted the data base management system, all the measurement data will be restored in the system data base, so that to enhance the software performance and more convenience in data management. The result statistic and result chart has been added in the data base screen for overview and comparison. Meanwhile, the measurement screen has been optimized for a vivid result display.

The CanNeed Seam Sight® Full Automatic Seam Monitor has adopted the advanced optical system and Golden Lens® video capture device, which interference-free of external light source and ensured the high image definition and the measurement accuracy. The Seam Sight® system is equipped with the new seam measuring software Seam Sight® .

|

|

|

Seam Sight(TM) 3B Portable Full Automatic Seam Monitor

|

|

The CanNeed "Seam Sight 3B Portable Full Automatic Seam Monitor" is so small and portable to work with a laptop. It was packed with the CSS-P2 into a suitcase, specially designed for those who always on business trip.

|

|

|

CSS-P3 Portable Seam Saw

|

The the CSS-P2 seam saw is so small and portable. It was packed with "Seam Sight 3B Portable Full Automatic Seam Monitor" into a suitcase, specially designed for those who always on business trip.

CanNeed “CSS-P2 Portable seam saw” is a special seam circular saw with double cut for can double seam inspections. The CSS-P2 was specially designed for 2- and 3-piece cans. Also aerosol-cans may be sawed with this saw. The nitrated blades achieve a very plain cut surface. The seam image on automatic seam measuring systems gets thereby very clear and improves measurement speed and reliability.

|

|

|

CanNeed-SM-24 Electric Belt Drive Seamer

|

The CanNeed "SM-24 Electric Belt Drive Seamer" (Desktop model) enables the users to do more lab tests. Such as, adjusting some technique, enhancing the products quality, test the empty cans and free ends, to insert a temperature logger into a can before running a temperature monitoring.

It is much more convenient for those lab tests, fast, easy and high efficiency

|

|

|

SLG-D Seam length gauge(digital)

|

|

The Canneed SLG-D Seam length gauge(digital) can be used to measure Seam length (Seam height).

Can is positoned by standing up during measuring.

With the Mitutoyo 0.01mm Resolution Digital Indicator.

If you purchase the adapter and cable,

the instrument can communicate with a computer.

|

|

|

CSM-208, CSM-207 Can Seam Micrometers (Fine tuning)

|

The CanNeed CSM series Can Seam Micrometers are use for measuring the seam thickness and length. The fine tuning function helps to avoid the deviation caused by over rotation.

CSM-208 is applicable to measure the seam thickness and length of flat bottom straight wall cans.

CSM-207 is applicable to measure the seam thickness and length of aerosol cans and necked-in cans.

|

|

| Total page:1

Current page:1 Total records:21 |

First | Previous | Next | Last

|

|

"If you can not find the product you need, please contact us or leave a message."

|

|