Description

Introduction

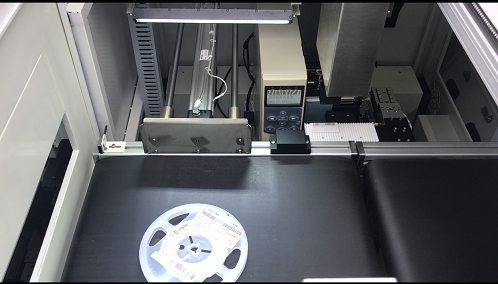

The CanNeed-Chip-A380 is a fully automatic machine for counting components on 7-inch to 15-inch reels and applying labels. Users can load reels via material carts. The equipment utilizes a robotic arm for automatic loading, automatically reads the reel ID, verifies the part number with the system, employs X-ray imaging for scanning and counting, automatically connects to the MES system for deduction, and performs automatic unloading, automatic labeling, automatic secondary verification scanning, and automatic sorting. It enables unattended automated counting operations, providing timely, accurate, and intelligent inventory management.

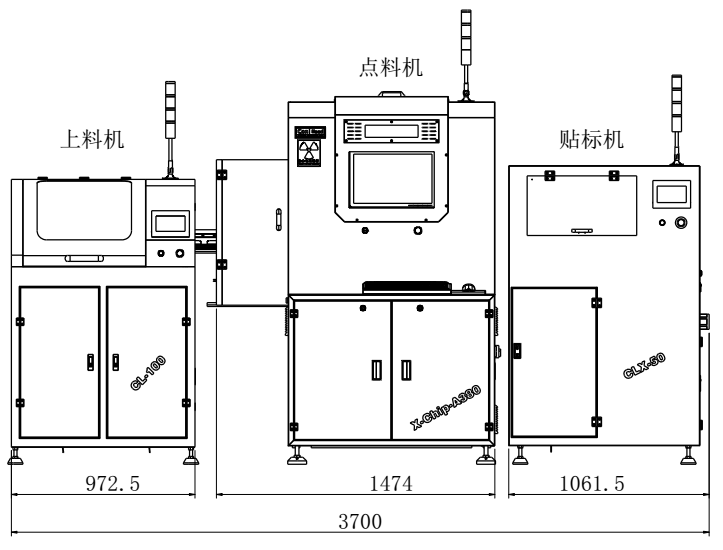

Equipment Dimension Diagram

Main Features

|

No. |

Description |

Image |

|

1 |

Dual-Station Design: Two independent storage stations capable of holding up to 104 reels total. Material carts can be replaced even while the equipment is running. High Compatibility: 7-inch to 15-inch reels can be stored and processed mixed without any impact on the |

|

|

2 |

Automatic Barcode Reading, EMS Connectivity |

|

|

3 |

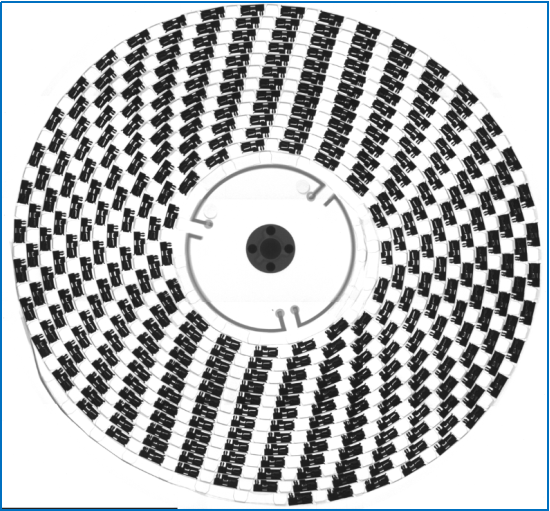

Acquires reel component images, performs image processing and counting |   |

|

4 |

Capable of counting tall components up to 68mm high – currently the only solution on the market meeting this requirement, with distortion-free imaging. |  |

|

5 |

Prints label content as required. New labels can overwrite existing labels on the reel. The reel can be rotated ±180 degrees. Vision-guided label application. Remembers the old barcode information and verifies consistency between old and new barcode information to prevent mislabeling. |

|

|

6 |

CE Certified |

|

Technical Parameters

| Component Counter Technical Specifications | Specification / Value |

| Scanning Size | 180mm – 380mm |

| Speed | ≤ 25 seconds |

| Component Size | Minimum CHIP size 0201 / 01005 |

| Reel Height Acceptance | 8mm – 80mm |

| Counting Accuracy | ≥ 99.7% |

| Tube Max Voltage | 100 kV |

| Tube Max Current | 4.5 mA |

| Tube Max Power | 150 W |

| Pixel Size | 0.138mm |

| Barcode Scanning Method | Automatic CCD Scanning |

| Label Application Method | Overwrite Automatic Labeling |

| Label Printing | Auto-connect to REP/MES systems, automatic barcode printing |

| Database | ERP system integration、MES System |

| Machine Dimensions | 3750mm (L) x 1700mm (W) x 1970mm (H) |

| Net Weight | 1710 KG |

| Power Supply | 220VAC ±10%, 50/60Hz |

| Power Consumption | 3 KW |