Description

1. Purpose

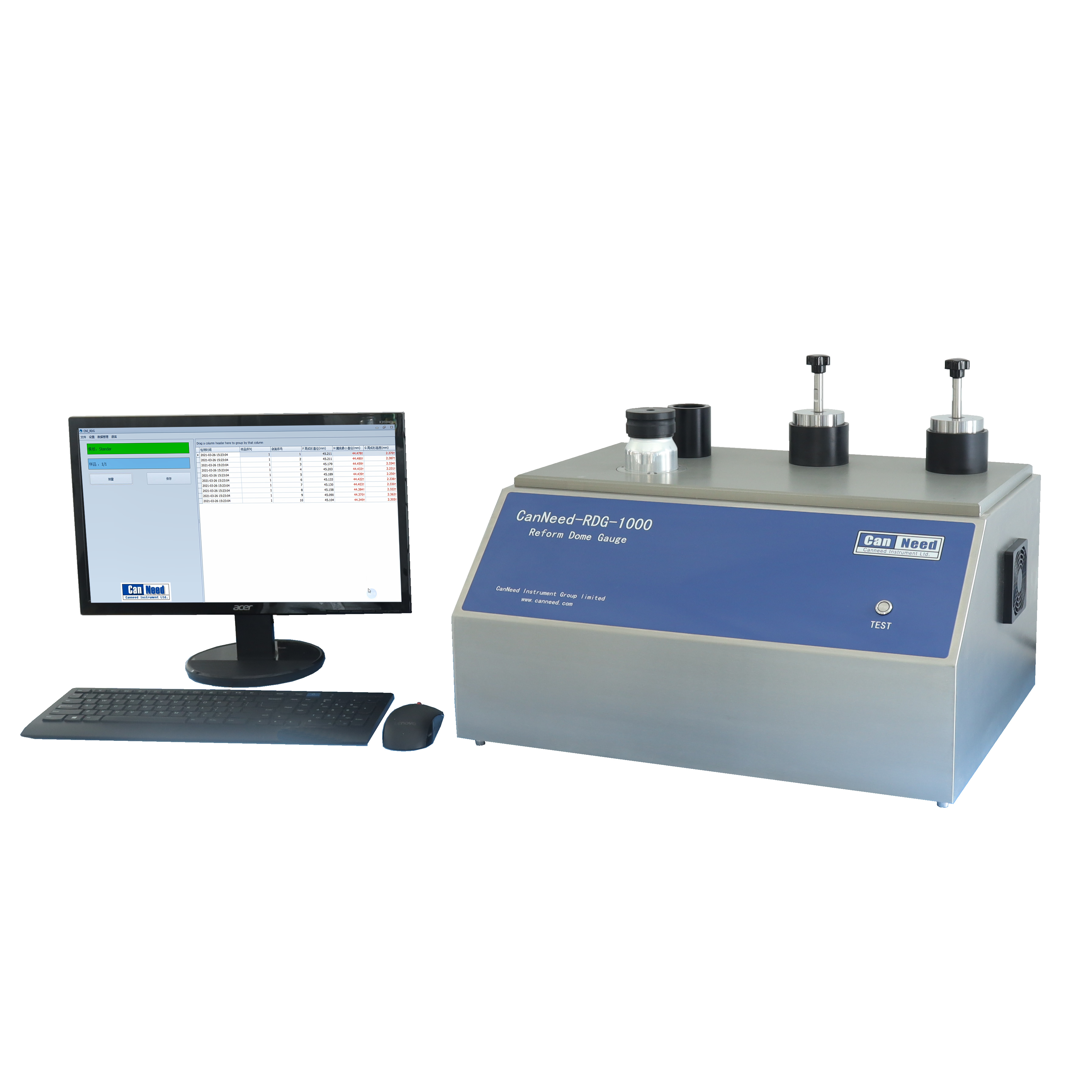

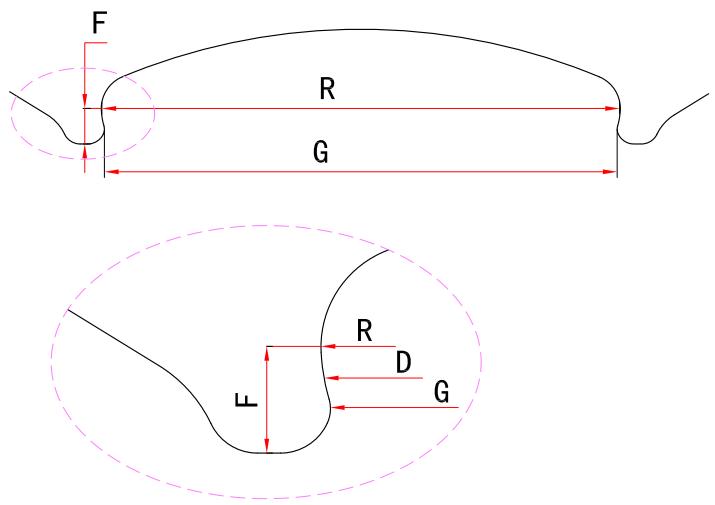

The CanNeed-RDG-1000 Automatic Can Bottom Reforming Dimension Gauge (Reform Dome Gauge) utilizes a non-contact, high-precision laser scanning sensor to rapidly scan the contour of the can bottom reforming area. By analyzing the contour curve, it obtains the two-piece can bottom’s reforming diameter (R), reforming height (F), minimum base diameter (G), and forming diameter at a preset height (D). This provides crucial data reference for ensuring can bottom pressure resistance while aluminum material is being thinned.

2. Measurement Process

1.Place the sample can into the test station.

2. Click the start button on the software interface.

3. The sample can automatically rotates 360 degrees (sampling points per rotation can be preset). The non-contact, high-precision laser scanning sensor quickly detects the contour of the can bottom reforming area, yielding measurement results.

4. The software automatically saves and sends the detection results.

3. Advantages and Performance

1.Non-contact laser automatic detection: Measures reforming diameter (R), reforming height (F), minimum base diameter (G), and forming diameter at a preset height (D).

2.World-class laser head for full contour scanning of the can bottom, with a measurement speed of 15 seconds/can.

3.No need to change or adjust any fixture parts; suitable for measuring sample cans of different heights, neck diameters, and body diameters.

4.Allows customization of test point locations and quantity.

5.Saves time and labor costs, avoiding human error.

6.Robust, durable, easy to operate, and maintain.

7.Measurement results can be sent to an SPC system.

8.Database management software facilitates querying and statistical analysis of measurement data for customers.

9.When multiple samples are measured, individual results can be reviewed, with automatic calculation of average, maximum, and minimum values.

10.Measurement results can be saved to Excel spreadsheets.

11.Multiple statistical charts; users can customize report formats to suit their company’s style and requirements.

4.Technical Specifications

|

Measurement Items |

1.Can Bottom Reforming Diameter

2.Can Bottom Reforming Height 3.Minimum Can Bottom Diameter 4.Can Bottom Forming Diameter at Preset Height |

| Unit |

mm |

|

Language |

Multiple languages available (Chinese/English) |

| Accuracy |

|

|

Speed |

15s/can |

| Power Supply |

230V/115V |

5.Instrument Configuration

| CanNeed-RDG-1000 Automatic Can Bottom Reforming Dimension Gauge

1、CanNeed-RDG-1000-M, Main Unit for Fully Automatic Comprehensive Can Back-End Dimension Gauge, includes: 1) RDG-1000 1.0 Software 2) Computer 2、AOBMS-CAL-** Calibration Column 3、RDG-1000-C** Test Fixture |

The following are optional: 4、QCtools Statistical Software |