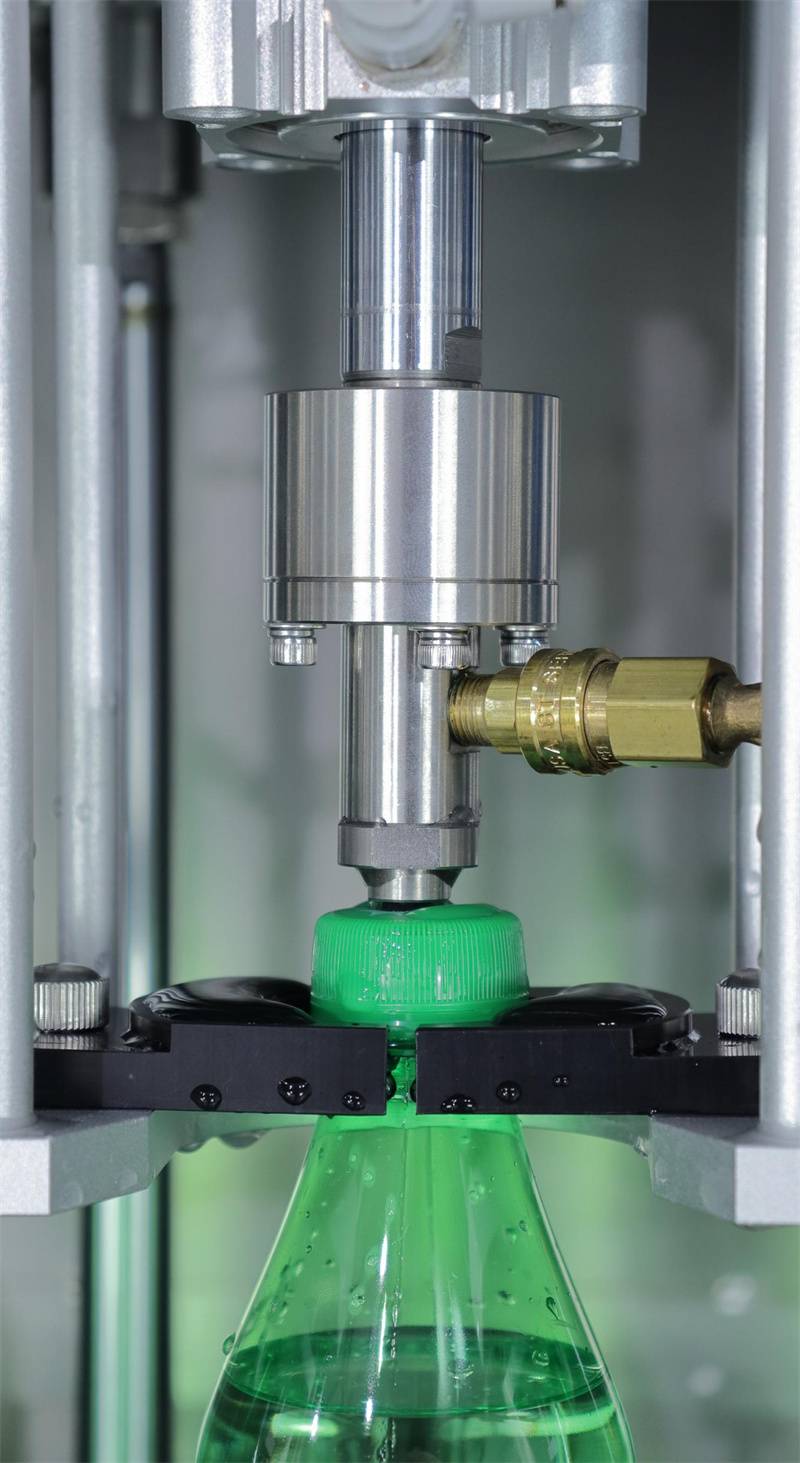

CanNeed-ASST-600 Automatic Secure Seal Tester is specially designed to test the seal integrity of PET bottles, glass bottles and the crown caps after packaging, prevent gas leakage and effectively control the sealing quality of the packaging cap. Comply with the national standard, line standard: GB/T 17876-2010 packaging container plastic anti-theft bottle cap. The ASST series products are widely used in beverage and brewing industries.

Recommended Standards of QuaIified SeaIing lntegrity:

|

PET bottIed beverages (non-aerated) , such as mineral water or tea drinks

|

0.2 MPa

|

|

PET bottled carbonated drinks, such as cola

|

1.0 MPa

|

Test process:

Clamp and place the sample containers into water tank and take pressure charge, then observe if there is gas leakage to judge the seal integrity.

Two testing methods: puncture method and cutting method.

*Piercing method for bottle capacity less than 1.5L, which is easy and fast to use.

*And cutting method for bottle capacity more than 1.5L to ensure safety in operation.

l Positive pressure method, 6 test heads, up to 6 samples can be tested in one time or optional number of stations for testing, much higher efficiency.

l Support multi-stage boosting/holding pressure, manual release, automatic puncture, pressurized test in water, and the results are automatically measured and saved.

l 10 kinds of sample test templates. The test conditions for different samples can be preset, such as segment pressure and holding time, and the subsequent test can directly call the bottle template, without the need to repeat the parameter setting.

l Touch screen control operation, the pressure unit can be MPa/psi.

l Test results viewed in the touchscreen interface, RS232 data output for SPC.

l Multiple safety features including safety valves, vents for rapid gas discharge, safety door locks, pressure reducers, safety guards, etc.

粤公网安备44120302000118号

粤公网安备44120302000118号