Description

Applications

X-Chip-A330 SMT Fully Automatic Component Counter is designed for inventory counting of returned materials in SMT warehouses and statistical analysis of related data. It is capable of fully automatic feeding, component counting, and labeling, while automatically uploading data to the MES system and integrating with smart warehouse systems. A single unit can save approximately 8-10 manual laborers while significantly improving the accuracy of inventory data.

Purpose of Implementing X-ray Component Counters

1.Increase Component Counting Speed

2.Reduce Labor Requirements for Component Counting

3.Improve Counting Accuracy

4.Automatic Integration with ERP System

5. Automated Integration with Smart Warehousing

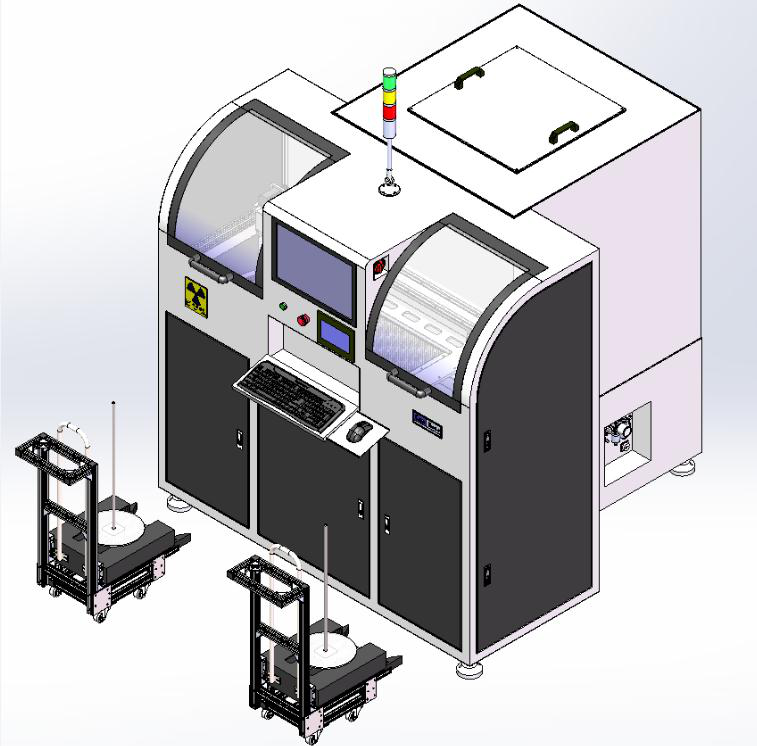

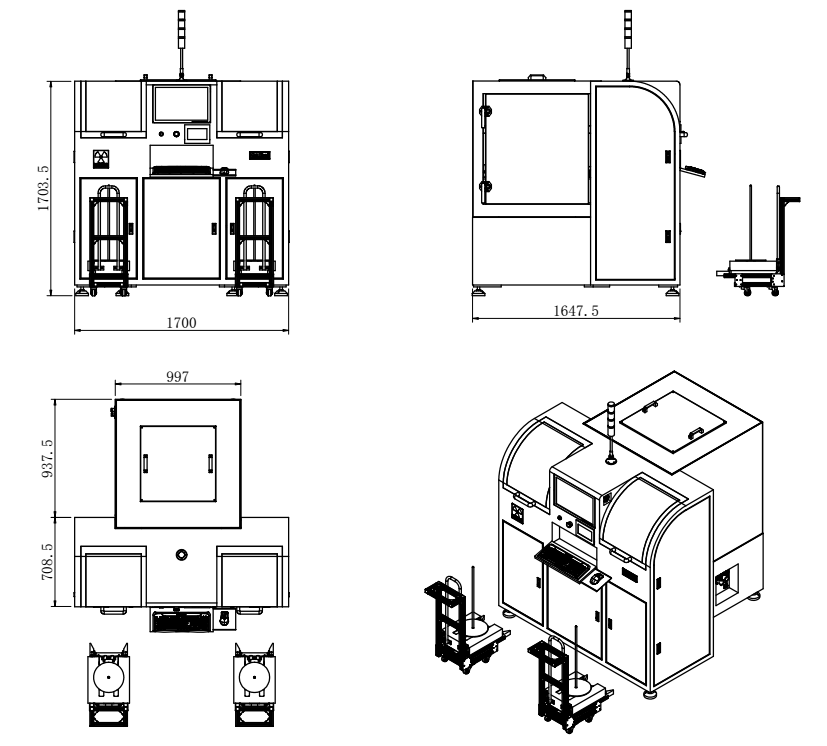

Appearance and Dimension Diagram

|

|

|

X-Chip-A330 Counting Machine |

Equipment Dimension Diagram |

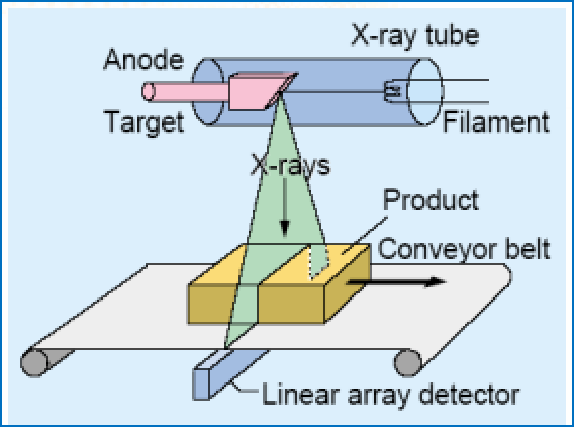

Working Principle Diagram

|

|

Technical Parameters

|

Description |

Parameter | Description | Parameter |

| Scanning Size | 180mm-330mm | Unloading Method |

Left & Right Station In/Out |

|

Speed |

20-22 seconds per reel | Machine Dimensions | 2100mm(L)x1650mm(W)x1700mm(H) |

| X-ray Tube Max. Voltage | 100KV | Net Weight |

1400KG |

|

Power Rating |

3KW | Power Supply | 220VAC±10% 50/60Hz |

| Component Size | Min. Size 01005 | Air Pressure |

0.5Mpa |

|

Feeding Height |

8mm-40mm | Operating Temperature | <40°C |

| Barcode Scanning Method | Automatic Scan | Relative Humidity |

Standard 70% @32°C |

|

Database |

ERP or MES System Integration | Safety |

Meets National Safety Standard <1µ Sv/h |