Description

Applications

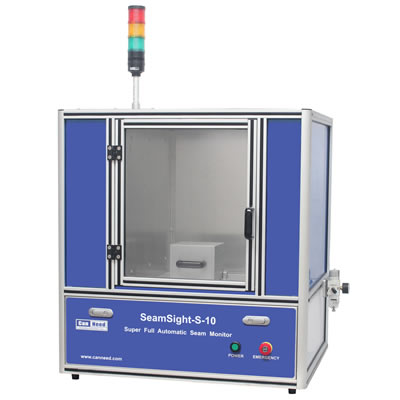

SeamSight®-S-10 A Combination of auto sampling, auto can cutting and auto measurement

Innovative invention of automatic can cutting and measurement seam monitor to replace the old manual can cutting measurement;

Innovative design enables the gauge to perform measurements on seam with minimal effort or Operator intervention. The operator only needs to put in and take out the empty can samples.

Operation Method:

1. Empty the contents from the sample can; rinse the can with clean water and dry the can;

2. Put the can in and close the cover;

3. Start the software, to finish auto cutting and measuring three sections;

4. Take out the can.

Automatic can cutting, automatic measurement; a

uto collect countersink digital indicator data;

ignore the interference of outer light sources; SPC data output;

5 optional formulae for seaming overlapped rate calculating;

customizable report format;

Advantages

2. Innovative invention of automatic can cutting and measurement seam monitor to replace the old manual can

cutting measurement;

3. Innovative design enables the gauge to perform measurements on seam with minimal effort or operator

intervention. The operator only needs to put in and take out the empty can samples.

4. Extreme safety and avoids the risk of injury resulted from manual can cutting;

5. High efficiency and auto finishing the whole measurement process;

6. Low noise;

7. High precision, clear display, equipped with the advanced Golden Lens® video capture device;

8. Repeatable and accurate measurement, adopting the auto cutting method to ensure a clear-cut cross-section

without deformation or burrs;

9. Simple, easy-to-use operation;

10. Stable performance and the seam saw made of hard metal alloy is durable;

11. Easy maintenance, drawer type cleaning of iron chippings and shavings, minimal care and maintenance;

12. The client chooses the proper can type along with the order, and chooses one from the following can types:113, 202, 206, 209;

13. Chuck number correlation of test data.

Technical Parameter

Resolution 0.001mm, Precision 0.005mm,

Magnification factor: 60 ×, Line

positioning magnification factor: 180 ×.