Description

Applications

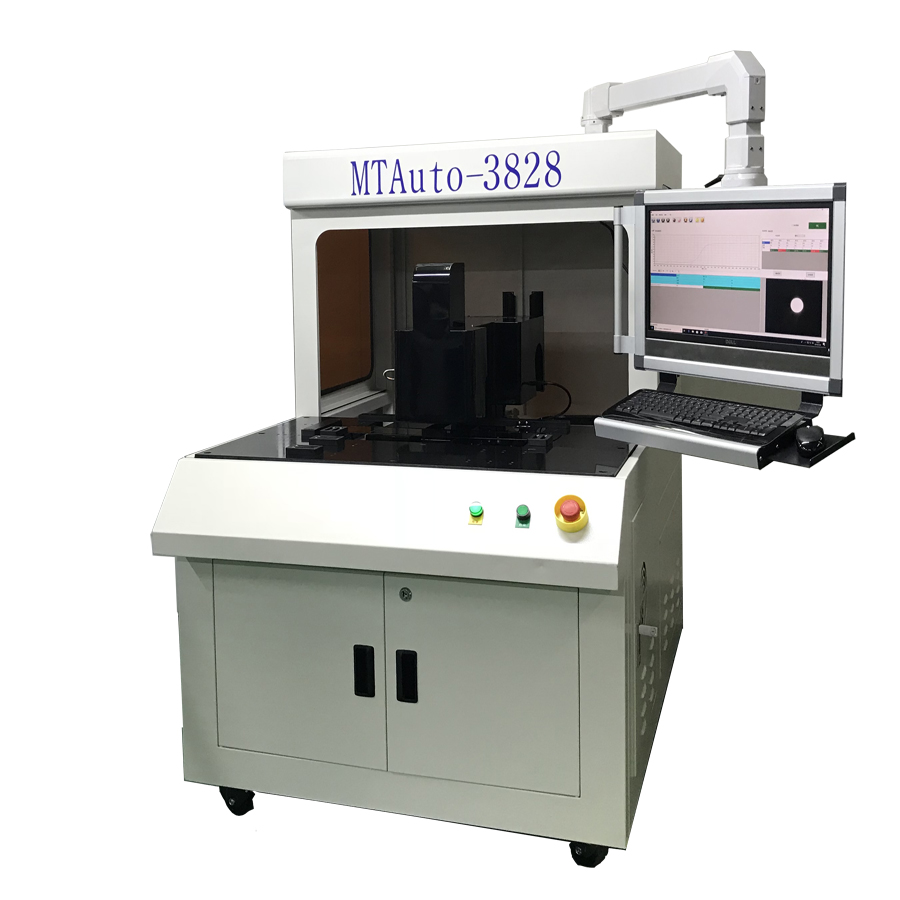

The MTAuto-3828 Automotive Glass Transmittance Tester is an automatic positioning inspection equipment designed for measuring the transmittance of large-sized glass cover plates with multiple IR apertures. Users can adjust the fixture to adapt to glass panels of various sizes, such as those used in automotive applications, car dashboards, navigators, and tablet computers. It enables automatic positioning and automated measurement, offering convenience, speed, and improved work efficiency.

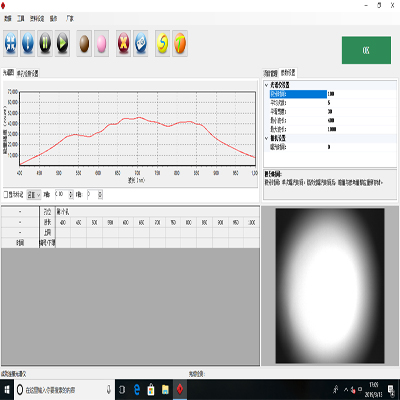

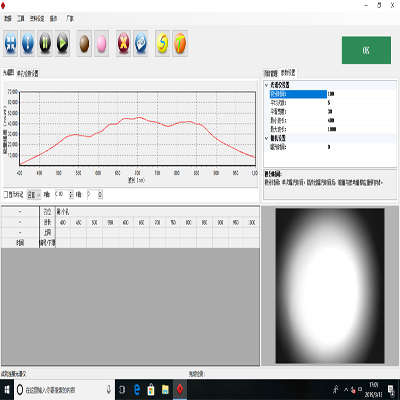

The system employs a professionally designed micro-spectroscopic optical path. The light source passes through the optical module and lens, focusing into a 0.2mm spot. This spot is directed through the product’s IR aperture or Icon into the spectrum collector, which then transmits the light to the spectrometer for analysis. An integrated camera allows observation of whether the measurement spot is precisely on the detection area, ensuring data accuracy.

Advantages

1.Automatic Positioning & Measurement: Automatically moves and takes measurements, eliminating human error for convenient and highly efficient operation.

2.Vacuum Adsorption Platform: The product platform uses vacuum adsorption for precise positioning.

3.Large-Range Motion Platform: Features a large travel range, offering wide adaptability.

4.User-Definable Inspection Criteria: Users can set detection requirements for each position, including characteristic wavelength and upper/lower limits.

5.Large Numerical Aperture (LNA) Technology:Utilizing an ultra-large numerical aperture of 0.22 in the fiber optic coupling and collection design, which significantly enhances the instrument’s sensitivity.

6.Integrating Sphere Collection Technology: Employs an integrating sphere for detection, completely resolving the defocus chromatic aberration issue inherent in conventional lens collection. Our high-energy technology fully addresses this problem, achieving detection times of just 100-200 ms.

7.Bottom Back-Illumination Technology: Incorporates a switchable structure between bottom illumination and integrating sphere collection, allowing users to easily observe if the spot is accurately positioned on the target, with excellent observation clarity.

8.Special Structural Design: The confocal design eliminates concerns about interference from ambient light, as external light cannot enter the system’s optical path.

9.Permanent Data Storage & Export: Data is permanently saved to a database and can be exported to Excel.

|

|

Technical Parameters

|

Parameter Category |

Specification |

| Detection Method |

Multi-point automatic positioning detection |

|

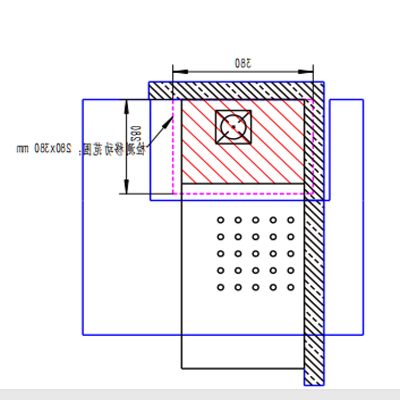

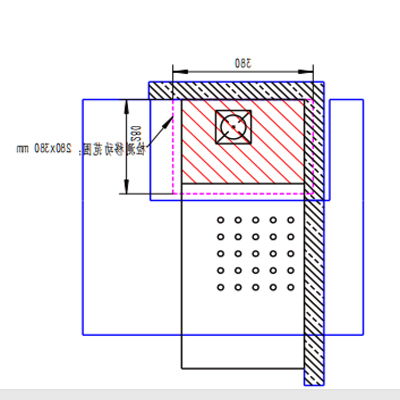

Movement Range |

280 X 380 mm |

| Sample Platform Size |

400 x 600 mm |

|

Measurement Spot Size |

0.15 – 0.5 mm (adjustable based on configured fiber and objective lens) |

| Detection Wavelength Range |

400 – 1000 nm |

|

Sample Stage |

Motorized X-Y Translation Stage |

| Measurement Error |

< 0.3% |

|

Wavelength Accuracy |

< 1 nm |

| Wavelength Repeatability |

< 0.1 nm |

|

Spectrum Collection Method |

Integrating Sphere |

| Transmittance Resolution |

0.01% |

|

Spectrometer Optical Structure |

Czerny-Turner |

| Fastest Full Wavelength Scan Speed |

8 ms |

|

Aperture Alignment Method |

Camera vision-assisted alignment (Observe spot position via software to avoid human error) |

| Detector Communication |

USB |

|

Spectrum Detector |

Back-thinned CCD Spectrometer |

| Light Source |

High-power Halogen Tungsten Lamp |

|

Positioning Accuracy |

0.02 mm |

| Light Source Lifespan |

2000 hours |

|

Single Aperture Test Time |

100 ms |