Description

Applications

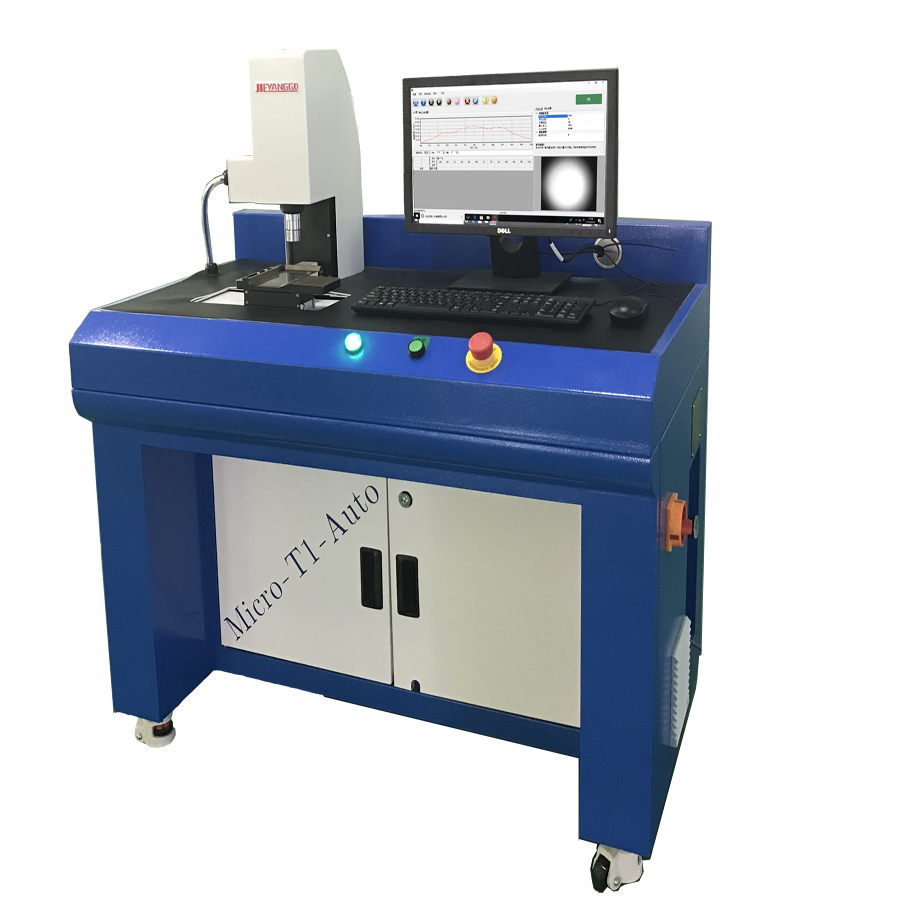

The Micro-T1-Auto Automated Positioning Transmittance Tester is an inspection system designed for automated positioning and measuring the light transmittance of multiple IR apertures. After the user sets the positions of the IR apertures and the measurement parameters, they simply place the mobile phone cover plate into the fixture. The system then automatically measures all IR apertures without requiring manual re-positioning for each hole, offering high efficiency, convenience, and significantly improved work productivity.

The system incorporates a professionally designed micro-spectroscopic optical path that confines the measurement spot to within 0.5mm. The use of an integrating sphere for light collection ensures more accurate and stable signal acquisition. Powerful, user-friendly operating software further enhances ease of use, while comprehensive data logging and reporting functions provide users with superior command over their measurement processes.

Advantages

- High Accuracy Measurement: Utilizes an integrating sphere for transmittance measurement, ensuring superior accuracy.

- Micro-Spectroscopic Optical Path: Features a small measurement spot of 0.15-0.5mm (adjustable based on user-configured fiber and objective lens).

- Back-Illuminated Spectrometer: Employs a back-illuminated spectrometer for low noise and high stability.

- Real-Time Visual Monitoring: A built-in camera allows real-time observation to ensure the detection spot is perfectly centered within the IR aperture.

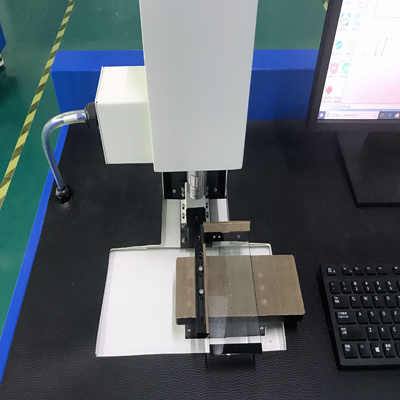

- Programmable XY Motorized Stage: Equipped with an XY motorized translation stage, enabling users to set the quantity and precise coordinates of IR apertures.

- Precision Vacuum Platform: The specially designed platform uses vacuum adsorption for precise and secure positioning.

- Flexible Software Settings: The software allows for easy setup and storage of product programs, including parameters for the number and position of IR apertures for different products.

- Multi-Wavelength Measurement Capability: The software supports wavelength configuration, allowing different IR apertures on the same product to be measured at different wavelengths.

- Permanent Data Storage: All measurement results are permanently saved in a built-in database.

- Comprehensive Reporting: Generate and print various reports, including single-wavelength transmittance reports for multiple IR apertures or continuous-wavelength reports for a single aperture. Reports can be exported to Excel, Word, or PDF.

- Safe & User-Friendly Operation: Designed for simple operation with one-touch startup, complies with Chinese national safety standards, and includes an emergency stop switch.

Technical Parameters

| Wavelength Accuracy | < 1 nm |

| Wavelength Repeatability | < 0.1 nm |

| Measurement Spot Diameter | 0.15 – 0.5 mm (varies with configured fiber and objective) |

| Testing Speed | 1 second per aperture + 1 second per piece (for A apertures) |

| Measurement Error | < 0.3% (using standard reference) |

| Transmittance Resolution | 0.01% |

| Spectral Collection Method | Integrating Sphere |

| Spectrum Detector | Back-thinned CCD Spectrometer |

| Spectrometer Optical Structure | Czerny-Turner |

| Fastest Full Wavelength Scan Speed | 8 ms |

| Aperture Alignment Method | Camera vision-assisted alignment (Observe spot position via software to eliminate human error) |

| Detector Communication | USB |

| Light Source | High-power Halogen Tungsten Lamp |

| Light Source Lifespan | 2000 hours |

| Sample Stage | Motorized X-Y Translation Stage |

| Positioning Aid | Built-in Vacuum Pump |

| Stage Travel Range | X-axis: 140 mm, Y-axis: 40 mm |

| Positioning Accuracy | 0.02 mm |

| Dimensions (L x W x H) | 1320 x 600 x 1200 mm |

| Weight | 200 kg |