Description

Introduction

The TRT-2100 is a fully automatic testing equipment designed for measuring the transmittance of multiple IR holes. Its structure is suitable for automated inspection of large screens, capable of automatically measuring large displays from 7 inches to 14 inches. Users simply place a stack of material trays, and the machine automatically measures the IR holes of all covers. No operator intervention is required for loading or unloading individual pieces. The machine performs fully automated detection, including loading, unloading, testing, OK/NG judgment, and rejection of non-conforming products. It can be integrated into production lines for intelligent and automated operation. Two units can be connected back-to-back, saving space and facilitating operation.

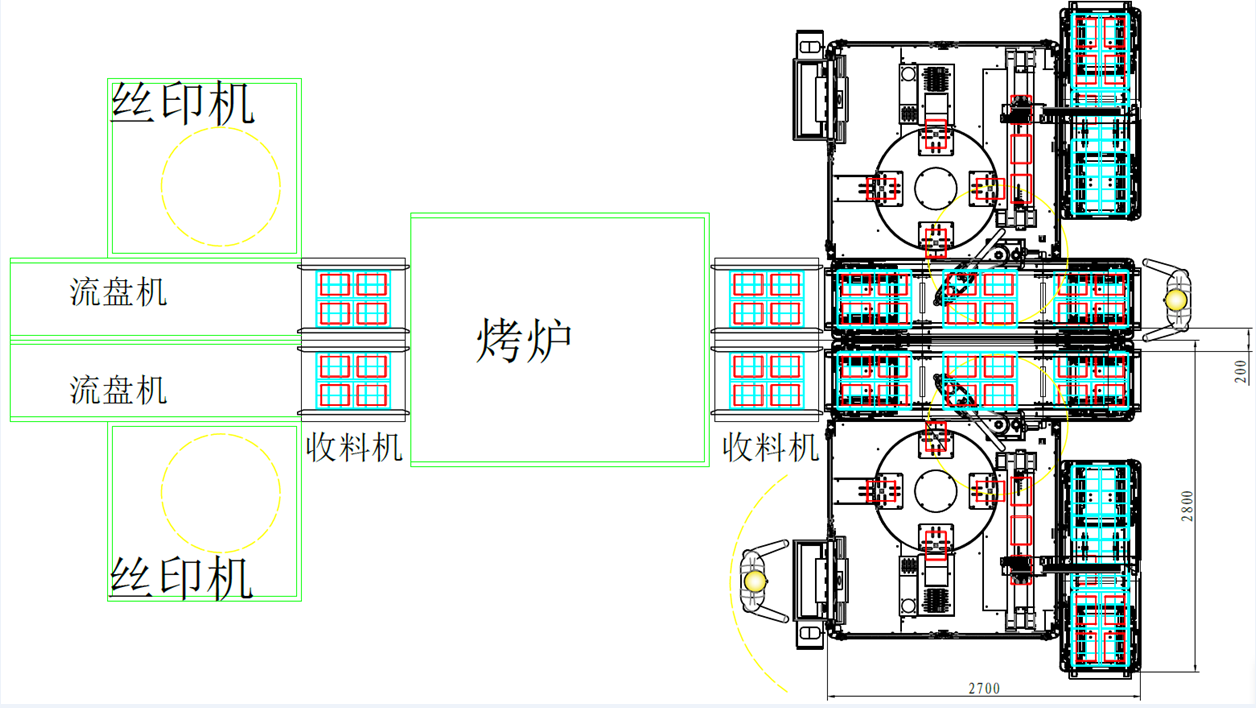

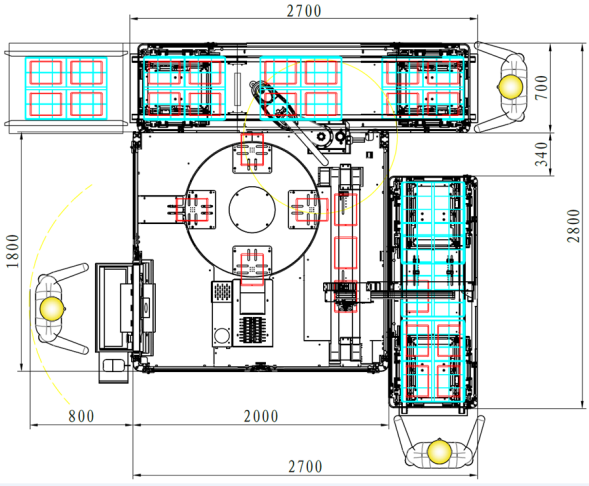

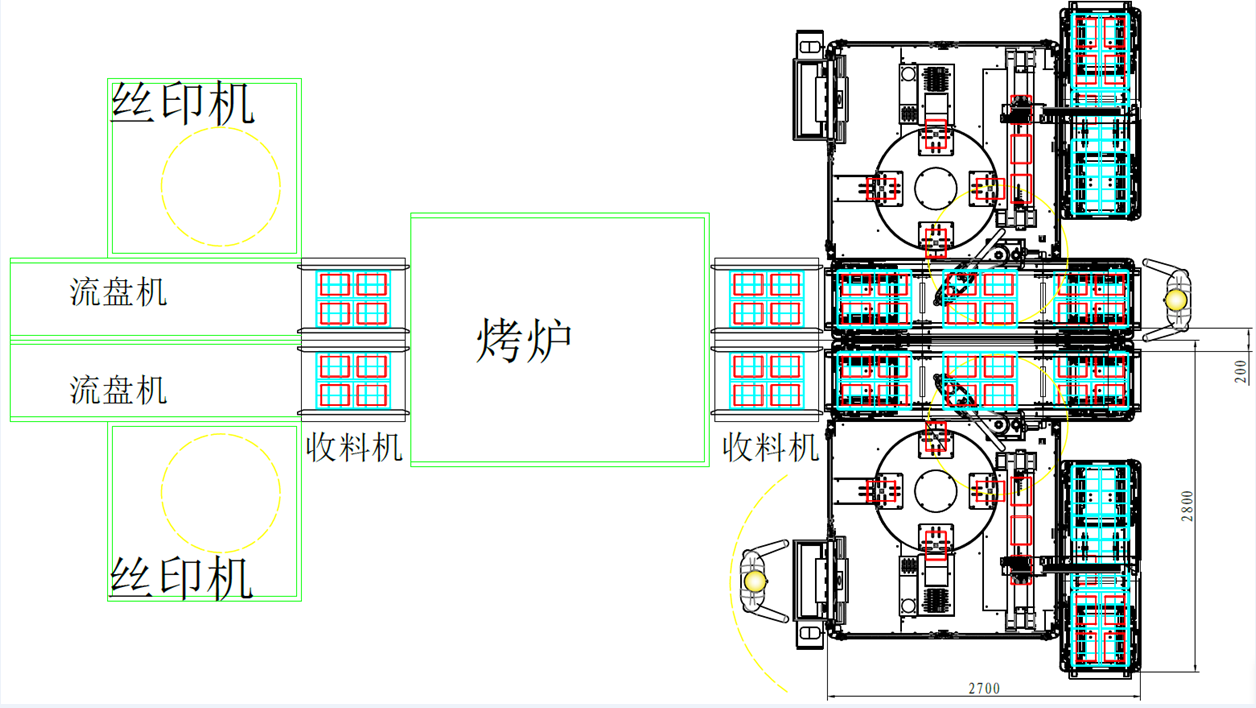

Overall Dimension Diagram

|

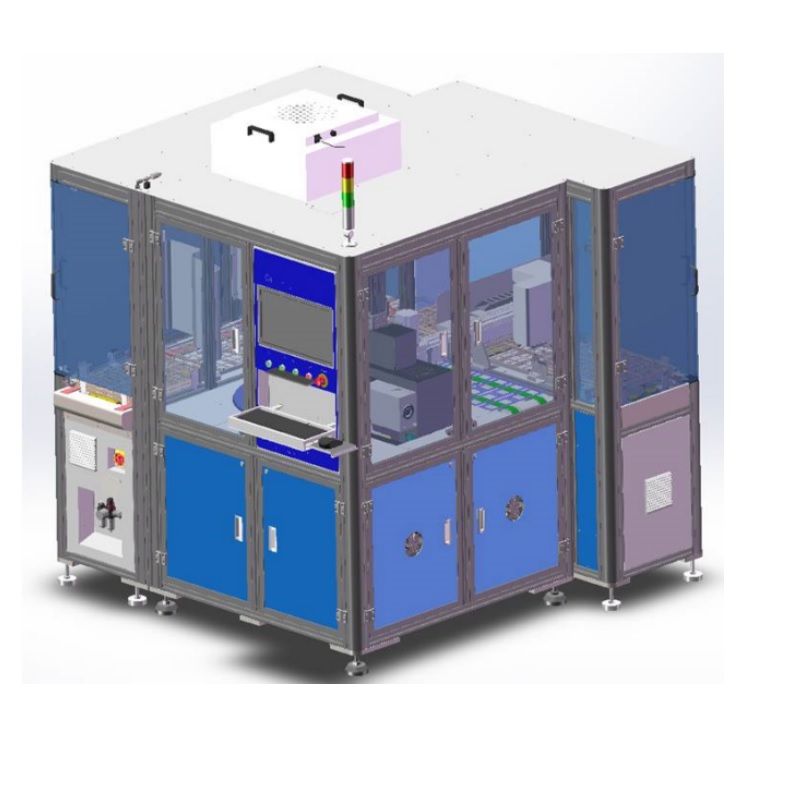

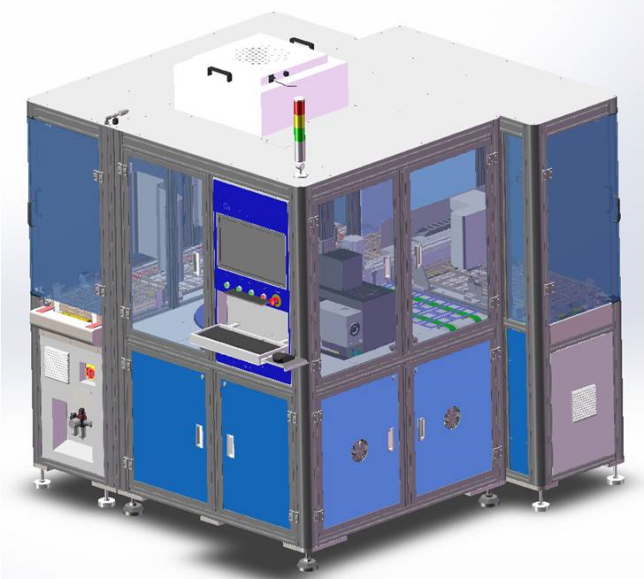

3D Appearance and Dimension Diagrams |

|

|

|

Outstanding Performance

- Direct Production Line Integration & Automatic Handling

1.1 Both the loading and unloading areas can stack 40 material trays each.

1.2 NG samples are automatically collected via material boxes.

1.3 OK products are automatically returned to their respective trays.

1.4 NG products are also returned to the trays, with automatic loading/unloading and recycling of the trays themselves.

2.Integrated System

The detection unit and automated motion system are integrated into a single system, offering easy operation and clear visibility of production information

3.In-House Design & Software Advantages The entire equipment, from the optical module and automated mechanical design to softwaredevelopment, is completed in-house.

Software advantages include:

3.1 Program Management: Save and recall product-specific parameters (IR hole count, position) for quick and easy measurement setup.

3.2 Flexible Wavelength Setting: Configure different measurement wavelengths for different IR holes on the same product.

3.3 Data Storage: Measurement results are saved to a local database and stored permanently unless deleted.

3.4 Reporting: Generate transmittance reports for multiple IR holes at a single wavelength or for a single IR hole across continuous wavelengths. Reports can be exported to Excel, Word, PDF, etc.

Parameters and Configuration

| Parameter | Specification |

| Detection Method | Fully Automatic |

| Detection Speed | 1000 pieces/hour (single-side speed) |

| Detection Wavelength Range | 400 – 1000 nm |

| Wavelength Accuracy | < 1 nm |

| Wavelength Repeatability | < 0.1 nm |

| Spectral Detector | Back-illuminated CCD Spectrometer |

| Spectral Acquisition Method | Integrating Sphere Collection |

| Optical Structure | Czerny-Turner structure |

| Detection Spot Diameter | 0.3 mm |

| Transmittance Detection Error | < 0.3% (using standard reference from metrology institute) |

| Display Resolution | 0.01% |

| Test Hole Alignment Method | Camera vision-assisted alignment (Observe spot position on IR hole via software, eliminating manual visual error) |

| Ambient Light Blocking | Patent-pending light trap cavity structure reduces errors caused by ambient light |

| Positioning Accuracy | 0.02 mm |

| Positioning Assistance | Built-in Vacuum Pump |

| Light Source | 100W High-power Halogen Tungsten Lamp |

| Warm-up Time | 10 minutes |

| Loading/Unloading Capacity | 40 trays |

| Alarm Mechanism | Three-color light + Buzzer |

| Control System | Motion Control Card |

| Handling Structure | Robotic Arm (600mm stroke) |

| NG Material Handling | Automatic boxing |

| Power Supply | 220 VAC |

| Equipment Dimensions (LxWxH) | 3500 x 2800 x 2000 mm |

| Equipment Weight | 3600 kg |

Note: Equipment acceptance and operational standards shall be based on the parameters listed above.