Description

Introduction

The CanNeed-Chip-A380 is a fully automatic machine for counting components on 7-inch to 15-inch reels and applying labels. Users can load reels via material carts. The equipment utilizes a robotic arm for automatic loading, automatically reads the reel ID, verifies the part number with the system, employs X-ray imaging for scanning and counting, automatically connects to the MES system for deduction, and performs automatic unloading, automatic labeling, automatic secondary verification scanning, and automatic sorting. It enables unattended automated counting operations, providing timely, accurate, and intelligent inventory management.

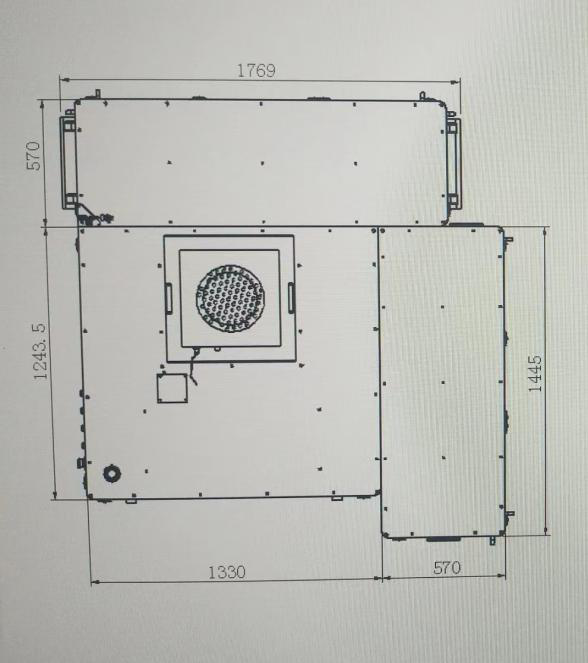

Equipment Dimension Diagram

Main Features

Testing Method Fully AutomatedLine Integration Compatible with Printing LinesTesting Speed 1100 – 1300 pieces/hourWavelength Range 400 – 1000 nmWavelength Accuracy < 1 nmWavelength Repeatability < 0.1 nmSpectral Detector Back-illuminated CCD SpectrometerSpectral Acquisition Integrating SphereOptical Structure Czerny-TurnerMax Full Spectrum Scan Speed 8 msMeasurement Spot Diameter 0.15 – 0.5 mm (adjustable via fiber optic and objective lens)Transmittance Error < 0.3% (using standard reference) Transmittance Resolution 0.01% Hole Alignment Method Vision System Assisted (software display for precise spot positioning, eliminating manual error) Ambient Light Rejection Specialized light-blocking structure Sample Size Range Length: 100 – 160 mm, Width: 50 – 90 mm (Customizable) Positioning Accuracy 0.02 mm Positioning Aid Built-in Vacuum Pump Light Source 100W High-power Halogen Tungsten Lamp Warm-up Time 10 minutes Loading/Unloading Capacity 40 trays per side Tray Handling Continuous Operation Alert System Three-color Tower Light & Buzzer Control System Motion Control Card Handling Mechanism Robotic Arm (400mm stroke) NG Material Handling Separate Collection Bin Power Supply 220 VAC Dimensions (L x W x H) 1840 x 1680 x 2030 mm Weight 1800 kg Note: Equipment acceptance and operational criteria shall conform to the specifications listed above.>

|

No. |

Description |

Image |

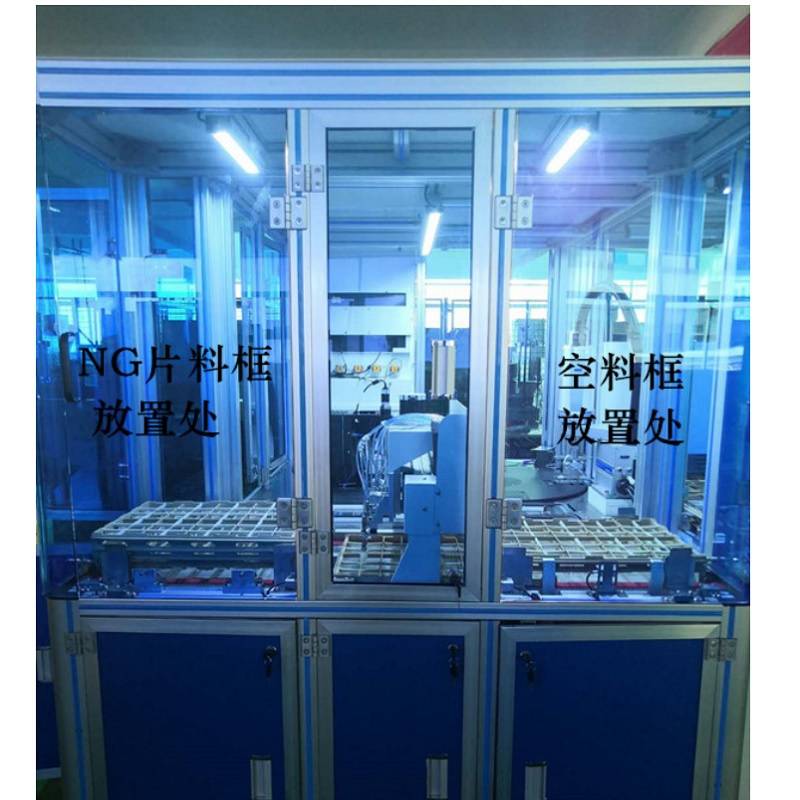

| 1 | FullAutomation:

Handles loading, unloading, and detection automatically. Loading and unloading areas each support stacks of 40 trays (typically 400 pieces total based on 10 pieces/tray). |

|

|

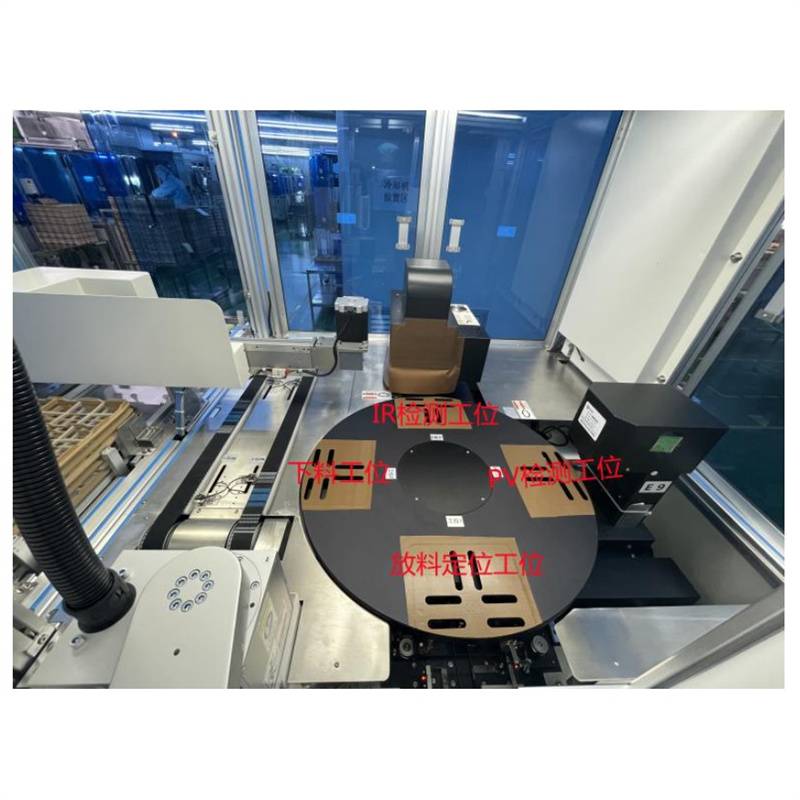

2 |

HighThroughput:

Four-station rotary table significantly enhances testing efficiency. AutomaticSorting: OK parts are returned to their trays; NG parts are dispatched to a dedicated rejection conveyor. |

|

|

3 |

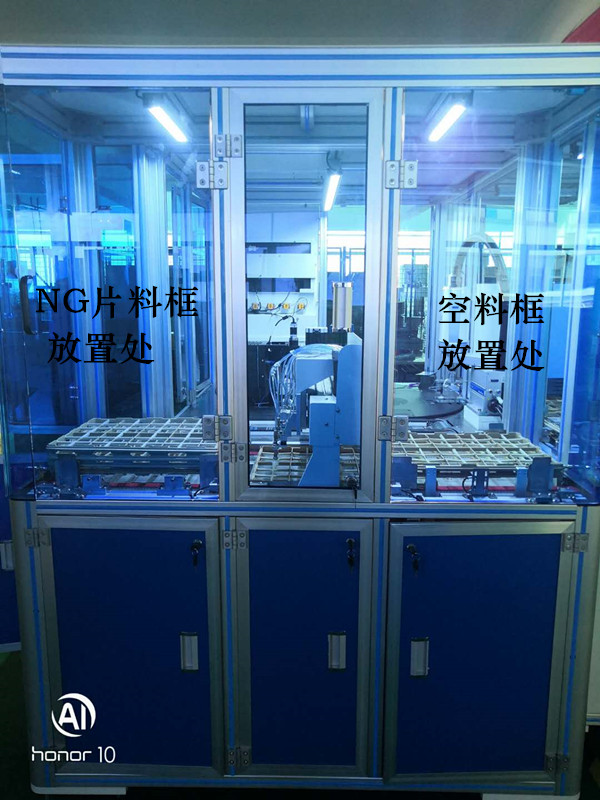

Streamlined Rejection Handling:

NG materials are automatically collected in designated containers, simplifying operation and reducing labor. |

|

|

4 |

Advanced Software Capabilities: 4.1 Program Management: Save and recall product-specific parameters (e.g., IR hole count/position). 4.2 Flexible Wavelength Setup: Measure different wavelengths for different IR holes on the same product. 4.3 Data Management: Results are permanently saved in a local database. 4.4 Reporting: Generate detailed transmittance reports (single/multiple wavelengths per IR hole) and export to Excel, Word, or PDF. |

|

Technical Specifications & Configuration

|

Specification Item |

Details / Value |

| Testing Method |

Fully Automated |

|

Line Integration |

Compatible with Printing Lines |

| Testing Speed |

1100 – 1300 pieces/hour |

|

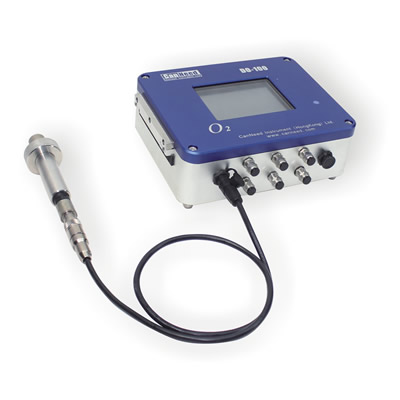

Wavelength Range |

400 – 1000 nm |

| Wavelength Accuracy |

< 1 nm |

|

Wavelength Repeatability |

< 0.1 nm |

| Spectral Detector |

Back-illuminated CCD Spectrometer |

|

Spectral Acquisition |

Integrating Sphere |

| Optical Structure |

Czerny-Turner |

|

Max Full Spectrum Scan Speed |

8 ms |

| Measurement Spot Diameter |

0.15 – 0.5 mm (adjustable via fiber optic and objective lens) |

|

Transmittance Error |

< 0.3% (using standard reference) |

| Transmittance Resolution |

0.01% |

|

Hole Alignment Method |

Vision System Assisted (software display for precise spot positioning, eliminating manual error) |

| Ambient Light Rejection |

Specialized light-blocking structure |

|

Sample Size Range |

Length: 100 – 160 mm, Width: 50 – 90 mm (Customizable) |

| Positioning Accuracy |

0.02 mm |

|

Positioning Aid |

Built-in Vacuum Pump |

| Light Source |

100W High-power Halogen Tungsten Lamp |

|

Warm-up Time |

10 minutes |

| Loading/Unloading Capacity |

40 trays per side |

|

Tray Handling |

Continuous Operation |

| Alert System |

Three-color Tower Light & Buzzer |

|

Control System |

Motion Control Card |

| Handling Mechanism |

Robotic Arm (400mm stroke) |

|

NG Material Handling |

Separate Collection Bin |

| Power Supply |

220 VAC |

|

Dimensions (L x W x H) |

1840 x 1680 x 2030 mm |

| Weight |

1800 kg |

Note: Equipment acceptance and operational criteria shall conform to the specifications listed above.