Description

Purpose

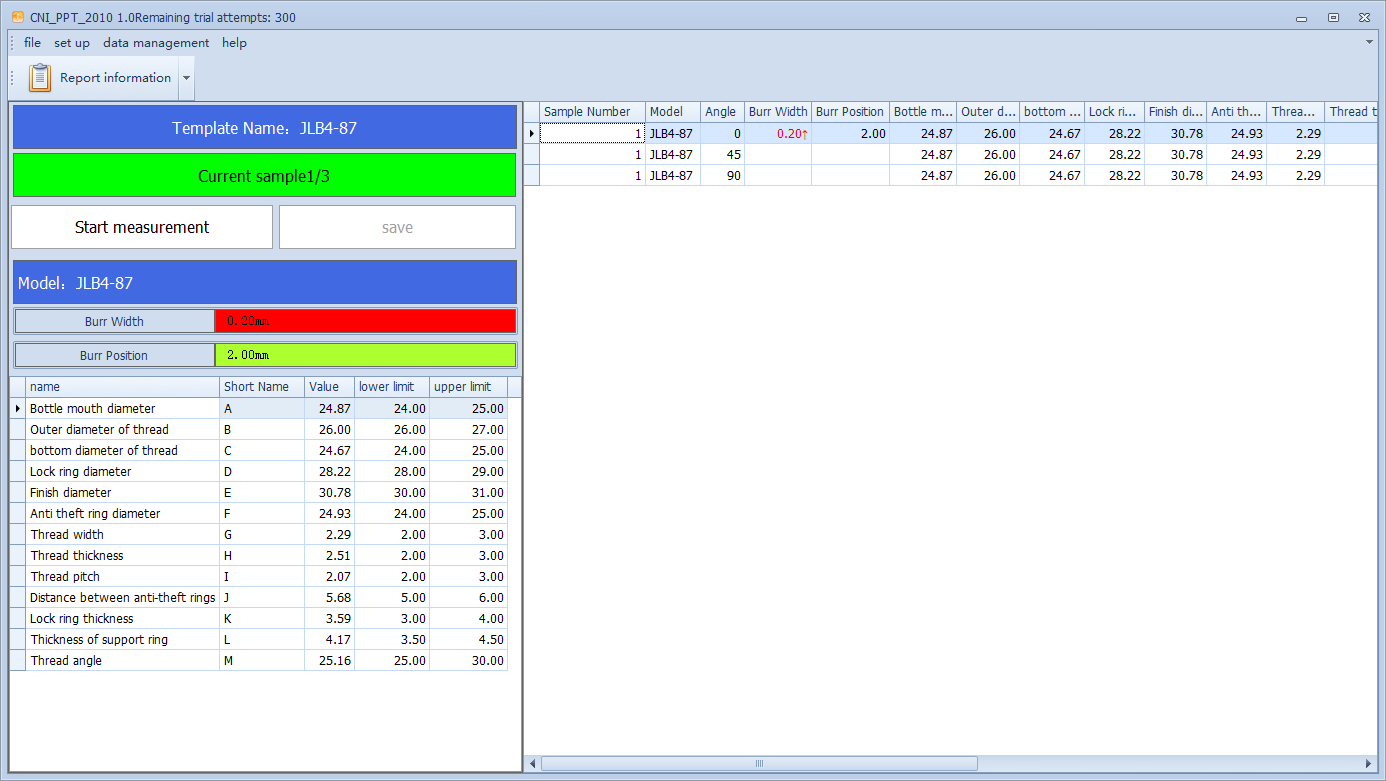

The CanNeed-PPT-2010 Preform Profile Tester is used to measure the external dimensions of PET preforms. The instrument uses a precision imaging system. The users only need to place the sample into the testing station and then click “Test” on the software. The users can gain the profile of the bottle mouths promptly and the system software automatically calculate the dimensions which need to monitor. It can provide the production system with prompt and effective quality feedback. Meanwhile, the data base can automatically save data and images, which provide the quality management with true data.

It uses a non-contact measurement method, which is more convenient and accurate. With one click, it can measure the size of the finishing, suitable for testing preform mouth with a height ≤ 30 mm and a diameter < 39 mm. It can also quickly change the bottle mouth positioning fixture during the production process to adapt to measurements of different bottle mouth diameters.

Benefits:

- Adopts an integrated design, is maintenance-free and easy to operate. After placing the sample, it can be measured with one click.

- Simple design, ergonomic and comfortable to use;

- Wide measurement range and is suitable for testing samples of different sizes and dimensions.

|

|

Technical parameters:

|

Measuring Items Accuracy:±0.01mm |

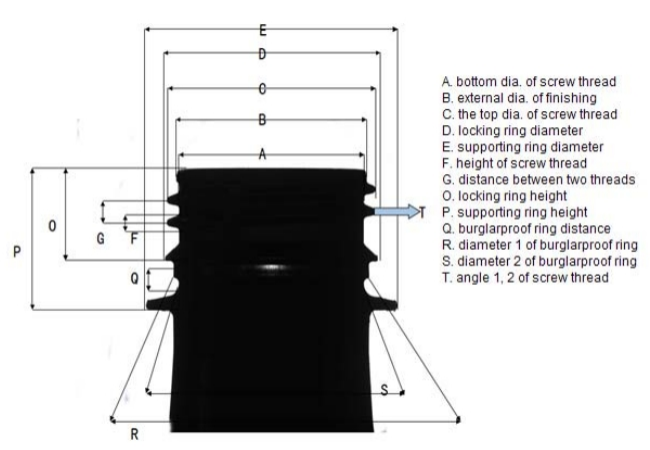

Preform Mouth Outer Diameter

Thread Outer Diameter Thread Bottom Diameter Thread Angle Width of Screw Thread Thickness of Screw Thread Height of Screw Thread Distance between Two Threads Diameter of Burglarproof Ring Distance between Burglarproof Rings Height of Bottle Mouth Supporting Ring Diameter Supporting Ring Position Full thread start position Full thread end position Locking Ring Diameter lLocking Ring position Flying edge width and flying edge position measurement accuracy ±0.05mm. |

| Preform dimension | Height of Preform Mouth≤30mm, diameter<39mm |

| Measuring speed | 1. Without rotation, only 1 point of external dimensions measurement, about 2.5 seconds;

2. Rotate 3 points of external dimensions measurement, about 11 seconds; 3. Fully automatic positioning + flash + 3 points measurement, about 20 seconds, 1 measurement station |

| Power supply | AC220V, no air source, no water source |

| Dimension | L940*W400*H450mm, Weight: 40KG |

| Environmental requirement | dry indoor working environment |