Description

Applications

Glass bottle containers may develop stress during manufacturing and processing due to various reasons, leading to bottle breakage during high-temperature sterilisation, filling, and other final processing stages, which can affect product production and testing. Stress testing of glass bottle containers evaluates their ability to withstand temperature changes without breaking.

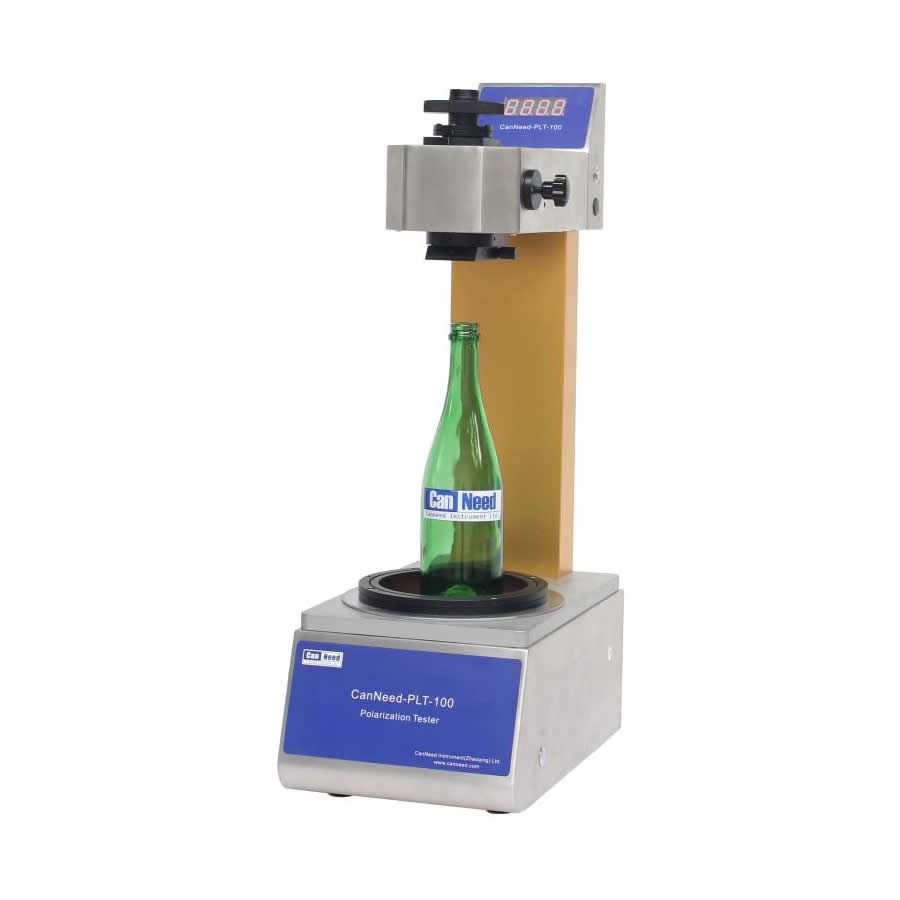

CanNeed-PLT-100 Glass Bottle Stress Tester is the ideal instrument for conducting stress tests on glass containers. It can detect internal stress in glass containers, enabling both qualitative and quantitative measurements. Designed in accordance with GB12415-1996 and GB4545-2007 standards, it is highly suitable for glass container manufacturers and beer/beverage producers. It plays a significant role in analysing and improving production processes, testing and inspecting glass bottles, and conducting incoming material inspections.

Advantages

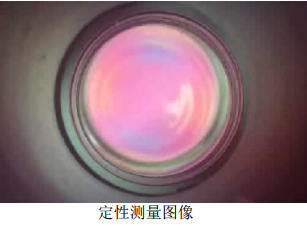

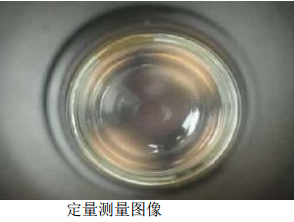

1) Can perform both qualitative and quantitative measurements.

2) Easy to use and accurate measurements.

3) Good compatibility, can test a wide range of sizes.

4) Digital display of test results.

5) With a calibration certificate.

Technical Parameter

- Power supply: 220VAC, 50Hz

- Angle measurement resolution: ±0.1º

- Sample type: Glass bottle container

- Bottle body diameter: ≤150mm (other diameters by order)

- Bottle height: ≤380mm (other heights by order)

- Angle measurement accuracy: ±1º

- Polarisation field diameter: ≤150mm

- Polariser workbench rotation angle: 360°

- Workbench dial scale value: 1°

- Full-wave plate optical path difference: 565nm

- High-quality polariser, polarisation degree: ≥99%

- Dimensions: 240x460x820mm

- Weight: 15kg