Description

Applications

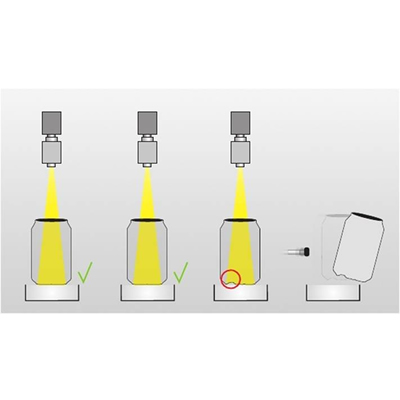

CanNeed-ICI-1000 is to test the empty cans with foreign body, impurity, dent and deformation before filling. And remove the unqualified empty cans before they affect the production of filling line and affect the product quality.

Advantages

1) The system uses the unique optical imaging hardware.

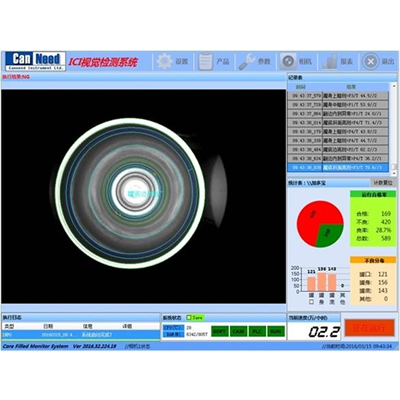

2) The system adopts excellent optical detection technology, with precise image processing method.

3) Testing speed ≥ 800 pcs per minute.

4) One-click button to test can quickly.

5) Remove defective cans reliably, and with remove confirming function to avoid missing elimination.

6) With the sound and light alarm system, can set a continuous NG number to stop the conveyor belt and alarm.

7) With test data statistics: qualified number, NG number, running time, defect classification number.

8) The modular system structure makes it easy to upgrade and update.

9) Self-service is available via a remote service connection.

10) Easy to install.

Technical Parameter

Design:

1) Adopt imported brand cameras and lenses to design unique optical imaging systems.

2) Adopt imported brand encoder and removal components.

3) Made of 304 stainless steel material.

4) Using high-performance industrial computers.

5) Both Chinese and English interface, easy to operate

Test indicators: