Description

CanNeed-BPT-4010 Ramp Pressure Tester is an advanced testing instrument for pressure testing glass containers, also can be used to do the passing tests and burst tests.

Applications:

Internal pressure resistance program is one of the most important safety indicators of beer bottle products, should be strictly in line with the internal pressure resistance requirements specified in GB-4544-2020. Otherwise, due to the lack of internal pressure resistance of beer bottles, it will cause beer bottles to burst and hurt people in the process of filling, transportation, consumption and use, thus affecting the reputation of the enterprise’s products.

CanNeed-BPT-4010 Ramp Pressure Tester is a professional instrument for testing the internal pressure of glass bottles!

Features:

- PLC controlled

CanNeed-BPT-4010 Ramp Pressure Tester adopts touch screen control, Chinese/English display mode, the operator only needs to follow the options on the display panel, select the required mode and options to complete the measurement requirements, simple and convenient to operate and use;

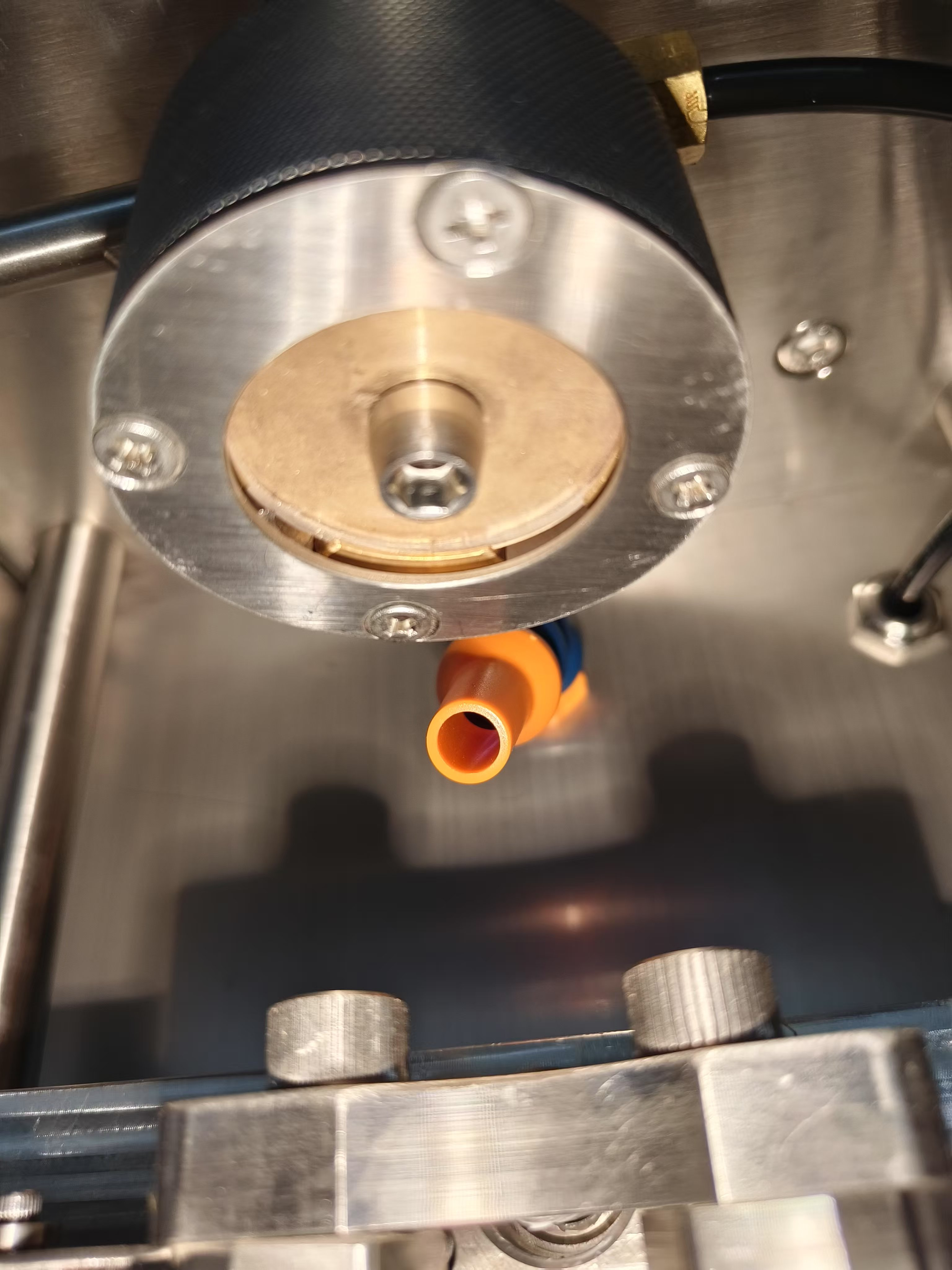

- Unique design of compensating sealing pressure head, automatic water-filling function

Compensated sealing pressure head, customers do not need to worry about the problem of bad sealing and air leakage due to excessive pressure; it has the feature that the higher the pressure, the tighter the clamping, the better the sealing, which avoids the trouble of air leakage. Automatic water-filling function saves time and improves efficiency;

- Double station, fast speed, high efficiency

CanNeed-BPT-4010 Ramp Pressure Tester features a double-station design, it can measure two samples at the same time, with fast measuring speed, which enhances the factory’s testing efficiency, increases the sampling rate and prevents product defects!

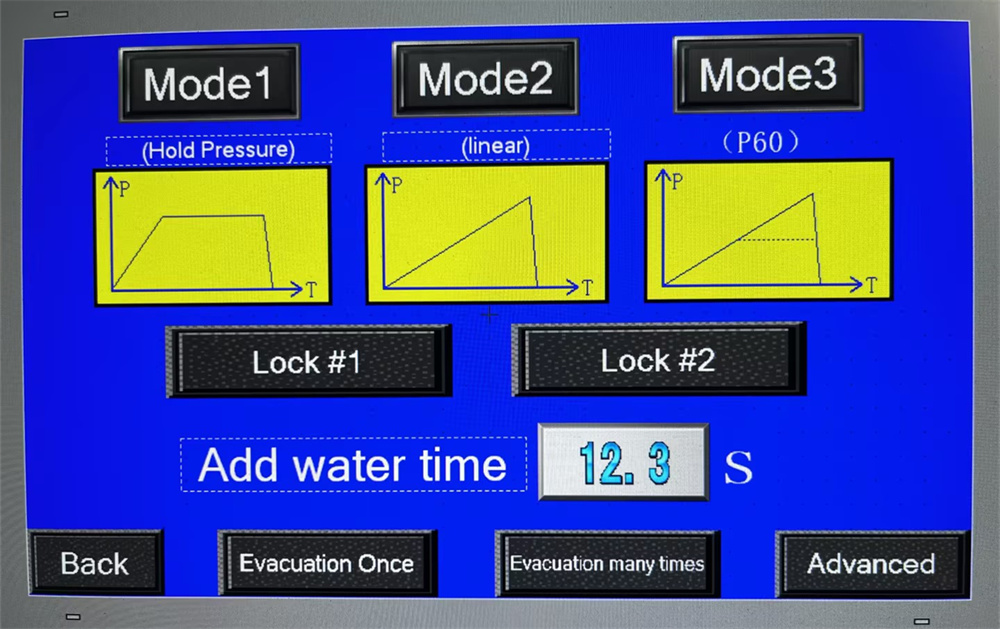

- Three (3) measurement modes to meet the different needs of customers

CanNeed-BPT-4010 Ramp Pressure Tester features three (3) measurement mode: pressure maintaining, linear pressurization and P60 mode. Multiple parameters are adjustable and settable to meet various measurement requirements of customers.

- Unique water, electricity and airseparation design, providing excellent waterproofing and extending the instrument’s service life

CanNeed-BPT-4010 Ramp Pressure Tester adopts a distinctive segregated design effectively isolates water splashed during bottle bursts, preventing the water from affecting other operations, thereby ensuring the overall safety performance of the instrument and prolonging its lifespan.

- Multi-layer sample collection, protective door design, automatic burstbottle push function, safer and more comfortable!

Equipped with a double-layer sample collection device, the test when the waste glass slag, waste water effective collection and processing, the bottom layer of water catching device, effectively preventing the flow of water to the ground, and the drainage outlet at the rear allows for quick water discharge to a designated location, maintaining the cleanliness of the usage environment;

The protective door design alleviates customer concerns about the door unexpectedly opening during measurement. With its unique design, the protective door remains closed until the measurement is complete, effectively protect the safety of the testers.

- Automatically save measurement data with data output function

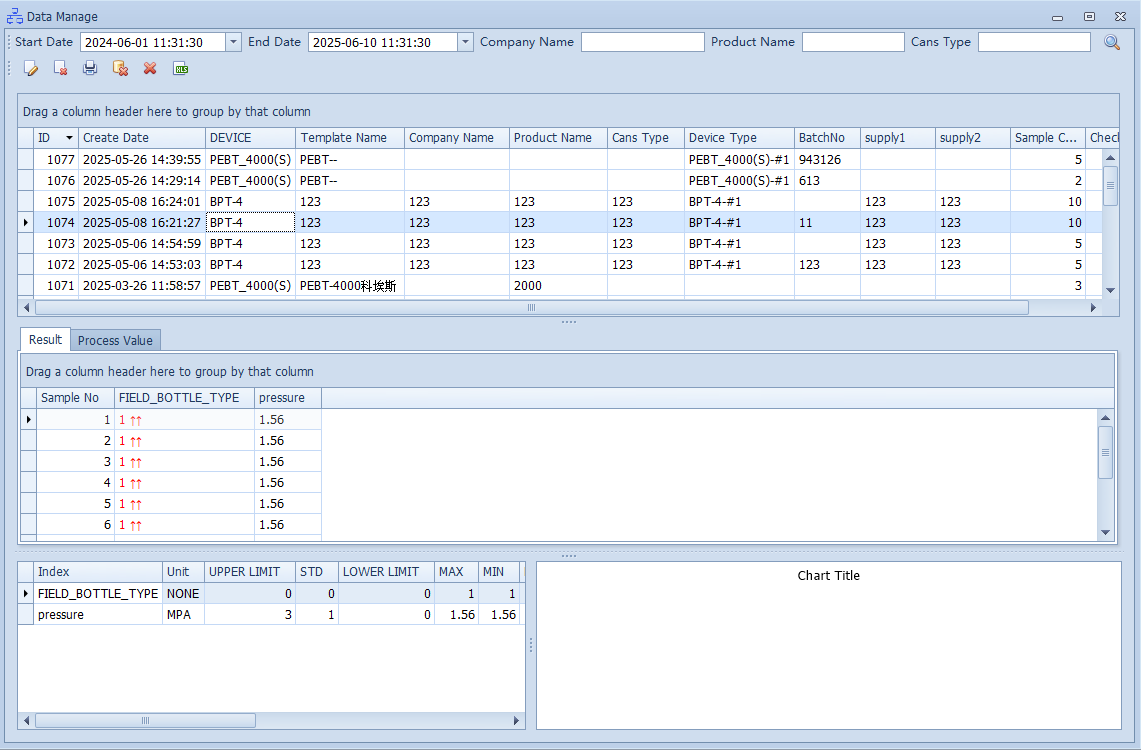

CanNeed-BPT-4010 Ramp Pressure Tester has automatic data saving function, can save 1000 measurement data, and with RS232C data output settings, customers can purchase CanNeed’s database software to save, export, print, check and other data management of measurement data.

Advantages:

- Automatic water-filling, automatic water replenishment, automatic sample clamping and automatic measurement;

- Automatic saving of measurement data, up to 1000 data;

- Automatic compensating sealing water injection head to prevent air leakage;

- Protective door with safety door lock to ensure the safety of the equipment;

- With RS232C data output function;

- Multi-layer sample collection, clean equipment, easy maintenance;

- Angle steel frame structure is more solid, good waterproof of water, electricity and gas separation;

- Servo motor control pressurization, good pressure repeatability and high precision;

Technical parameters:

| Item code | CanNeed-BPT-4010 |

| Measure range | 0–6 MPa |

| Resolution | 0.01Mpa |

| Water supply | 0.15–0.3 Mpa |

| Air supply | 0.4-0.5MPA |

| Working temperature | 0-50º C |

| Power supply | 110-120 or 220/240VAC, 50/60 Hz |

| Output interface | RS232 data output |

| Machine dimension | 880mm*1030mm*1600mm |