Description

Applications

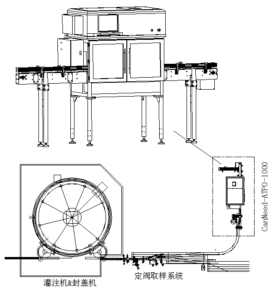

CanNeed-ATPO-1000 Full Automatic Beverage Total Package Oxygen Analyzer system can be installed and used in the production line or off-line.It can achieve the real-time monitoring of the total oxygen in beer automatically without manpower. Meanwhile it has a powerful data analysis function. According to the total oxygen fluctuation level measured on the corresponding wine valve, the data analysis system can analyze whether the wine filling valve is in good condition, and makes abnormal warning in advance to avoid the occurrence of quality accidents.

Testing Items: Total oxygen (TPO), Carbon dioxide(CO2), Empty volume in the bottle(HSO)

Principle

CanNeed-ATPO-1000 Full Automatic Beverage Total Package Oxygen Analyzer system design principle:

Fully automatically achieve: Sample transmission, sample pretreatment (gas-liquid equilibrium, constant temperature) and measuring beer parameters (Dissolved oxygen, Pressure, Temperature, Empty volume in the bottle, CO2).

According to the traditional Uhlig formula: TPO=DO*Z to calculate the total oxygen value.

Using the world’s most advanced optical sensor (Fluorescence method) which is sensitive response and high accuracy. Can achieve the multi-parameter measurement of beer by using a small number of samples.

Measuring process

- Start the software and use the ID-sampler-1000 Identification Valve Sampling Systemto take the sample from corresponding perfusion head number after the seaming machine.

- Samples were automatically delivered toCanNeed-ATPO-1000.

- Without personnel on duty, the software controls the whole process of measurement.

- The sample is automatically shake, and then transported to the measuring station by the manipulator to complete the measuring tes

- Save all the measurements automatically to the database.

Advantages and Performance

- Online automatic measurement, fast and efficient

- Unattended, save labor costs

- Measure more accurate and avoid artificial measurement error

- Fast inspectionspeed and high sampling frequency to reduce the isolation of defective products

- Real-time monitoring of the production line filling stability

- Provide important data for evaluating the operation statusof the production process.

- The measurement data can be automatically savedin the SPC.

ATPO-1000 Software Function

- Can establish multiple sets of inspection qualification standards,can automatically judge and warn whether the measurement result is qualified.

- Users can customize the report formatwhich is suitable for the enterprise’s own styl

- A variety of statistical charts to facilitate the statistical analysis of the data.

- Measurement can be saved to the excell sheet.

Configuration

Please communicate with us in advance about the installation layout.

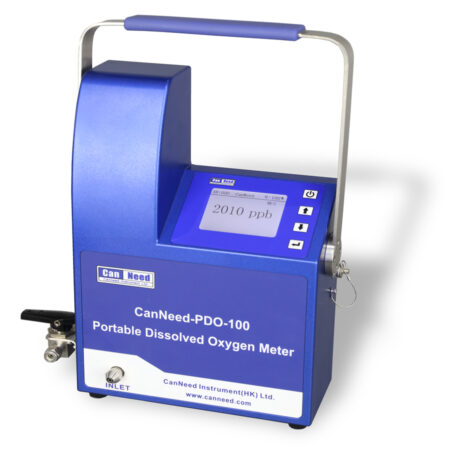

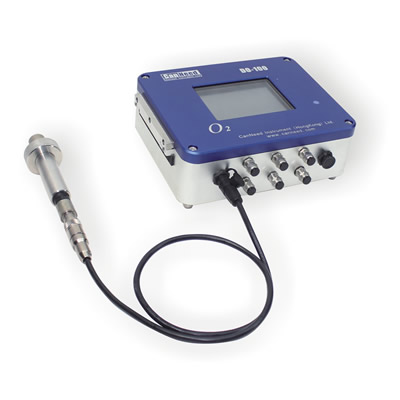

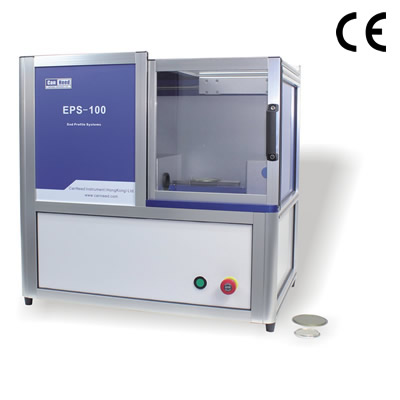

| 1. CanNeed-ATPO-1000 Full Automatic Beverage Total Package Oxygen Analyzer Mainframe

Including: 1) ATPO Measring Mainframe 2) ATPO Manipulator 3) ATPO Bottle Shaking Mechanism 4) ATPO Control System 5) ATPO Conveyor line 6) Positioning bottle fixture, Pressing bottle fixture |

2. Optional

a) ATPO-LINE Connected conveying line ( For connecting ATPO-1000 to the wine filling machine, customized ) b) ID-Sampler Identification Valve Sampling System c) CT-100 Thermostatic control system

3. Vulnerable parts: Puncturing needle kit |

Technical Parameter

Installation Site: bottled production line, canning production line

Installation Requirements: Water, Compressed Air(>5bar), High-purity N2 (N2>99.999%)

Power: 220V /10A

Applied for bottle type: Bottle Diameter≤110mm, Bottle Height ≤320mm Crown cap bottle type. For the special bottle type, it will need to be evaluated.

| Parameter | Measuring range | Accuracy | Unit |

| Total oxygen | 0 – 2000 ppb | ±2% | ppb |

| 0 – 2000 ug/l | ug/l | ||

| 0 – 2.0 ppm | ppm | ||

| 0 – 2.0 mg/l | mg/l | ||

| Dissolved oxygen | 0 – 2000 ppb | ±2% | ppb |

| 0 – 2000 ug/l | ug/l | ||

| 0 – 2.0 ppm | ppm | ||

| 0 – 2.0 mg/l | mg/l | ||

| Bottle neck space | 0-80ml | ml | |

| Temperature | -5.0—40 ℃ | ±0.1℃ | ℃ |

| 23.0—104 ℉ | ℉ | ||

| Pressure | 0.0—5.0 Bar | ±0.02bar | Bar |

| 0.0—72.5 Psi | Psi | ||

| CO2 | 2—15 g/l | ±0.1 | g/l |

| 1—7.5 Vol | Vol | ||

| 0.2-1.5 %B.W. | %B.W. |