Description

Product Application

1. Instrument Introduction:

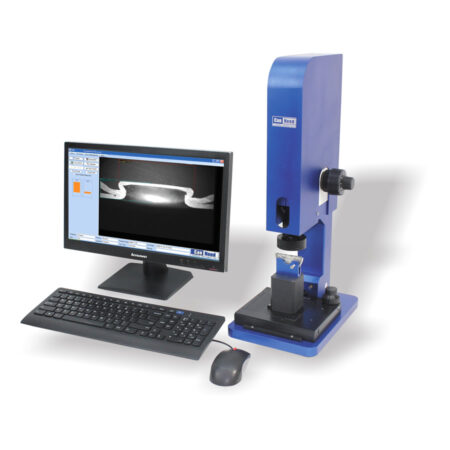

The CanNeed-APG-1000 Automatic Bottle Wall Thickness and External Dimension Gauge is a non-contact, one-click automatic measurement device. Its primary function is to fully automatically measure the external dimensions and thickness of PET bottles, glass bottles, etc., as well as the external dimensions of both transparent and opaque containers.

2.Test Items and Functions

a) Total Height

b) Sectional Height

c) Diameter: Maximum and minimum diameters around the bottle body

d) Thickness: Maximum, minimum, and average thickness around the bottle body

3. Measurable Parameters, Range, Accuracy, Resolution, Unit, and Measurable Points

a) Measurement Range: Bottle height 70-380mm, Bottle body diameter/width 40-160mm, Thickness less than 10mm

b) Field of View: Width 180mm

c) Measurement Accuracy: Height and diameter better than 0.5mm, Thickness better than 0.003mm

d) ① Number of Samples per Placement: 1

② NG Sample Retention Method: Manual handling

③ Maximum Retainable Samples: 1

e) Calibration Method:

① External Dimensions: Manual placement of calibration pillar, input of actual value, automatic calibration.

② Thickness: Manual placement of calibration sheet, input of actual value, automatic calibration.

f) Instrument External Dimensions:

① (L×W×H) 930×750×1200 mm

② Weight: Approximately 150 kg

③ Power Supply: AC 220V 50Hz

g) Safety Design:

① Aluminum profile chassis

② Operation protective door

4. Measurement Principle

Measurement Method: Optical

Technical Principles:

a) External dimensions: Backlight machine vision inspection.

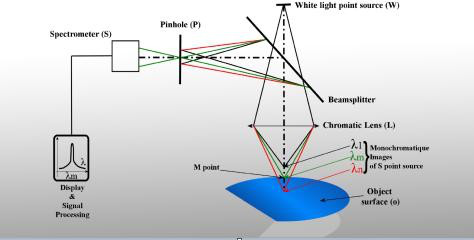

b)Thickness: Spectral confocal technology.

|

|

5. Measurement Process:

The CanNeed-APG-1000 Automatic External Dimension Gauge employs a precision imaging system. The operator simply places the sample, clicks ‘Measure’ in the PC software, and instantly obtains the bottle’s external profile dimensions. The system software automatically calculates the dimensions requiring monitoring, providing rapid and effective quality feedback for the production system. Simultaneously, the database automatically saves data and images, offering more authentic traceable data for quality management.

6. Product Advantages:

a)Operated via dedicated software connected to an external desktop PC, offering simplicity and convenience.

b)Real-time display of current data.

c)Non-contact measurement.

d)Programmable routines enable one-click measurement for all data, reducing labor and minimizing human measurement variation caused by manual point selection.

e)Permanent data storage allows for easy querying, and data can be exported and printed in .xls format.