Description

Applications

When beverage companies need to rapidly switch product varieties on production lines, a large volume of inspections must be completed within a short time. CanNeed’s CanNeed-AMS-Bev-1060 fully automatic bottled beverage multi-parameter inspection machine meets customers’ needs for fast, automated testing.

The CanNeed-AMS-Bev-1060 automatically measures the following items:

1.Liquid level.

2.Net content (by weighing).

3.Sealing angle.

4.Torque.

5.Cap seal tightness.

The above five inspection items can be selected and customized, and the system can also be extended to include more inspection items, such as:

6.Headspace oxygen content

7.Internal pressure or CO₂ content, etc.

Featuring fully automatic conveyor belt feeding, samples are transported to the measurement station where inspection is performed entirely automatically, eliminating the influence of human

Technical Advantages

1.Fully automated detection, saving manpower.

2.Multiple parameters are measured sequentially on a single sample, reducing sample consumption.

3.Multiple workstations operate simultaneously, ensuring fast detection speed and quicker generation of test results and reports.

4.Fully automated conveyor belt feeding, automatic measurement, and automatic placement into the waste bin after completion.

5.Compatible with a wide range of sample types, including various round and square bottles, with broad diameter and height tolerance.

6.Simple and convenient maintenance.

7.Stainless steel construction.

8.Automatic data transmission via data interface.

9.Storage capacity for up to 1,000 measurement records.

10.Optional sampling methods: 1) Manual sampling and loading, supporting up to 120 samples on the feeding conveyor module; 2) Automated sampling connected to the production line.

Technical Specifications

| Liquid Level Measurement Range and Accuracy | Accuracy:±2mm |

| Net Content Measurement Range and Accuracy | Range:1 – 2000g,Accuracy:±0.01g |

| Sealing Angle Range and Accuracy |

Range:0 – 180°; Accuracy: Equivalent to the angular range of one gear tooth width |

| Torque Measurement Range and Accuracy | 00.00 – 10N.m(100Kgf.cm),Accuracy:±0.5% |

| Sealing Tightness Measurement Range and Accuracy | Range:0 – 1.2Mpa;Accuracy:0.1Kpa |

| Bottle Height Range | Range: 150 – 330mm,Customizable |

| Cap Diameter Range | Range:27.5 – 50mm,Customizable |

| Bottle Body Diameter Range | Range:48 – 90 mm,Customizable |

| Data Interface |

RS‑232 serial cable; automatically saves and transmits results to a computer |

| Power Supply | AC220V,50Hz |

| Air Supply | 0.4 – 0.6MPa |

| Body Material | Stainless steel |

| Operating Conditions | Temperature 0~45℃,Humidity 0~85% |

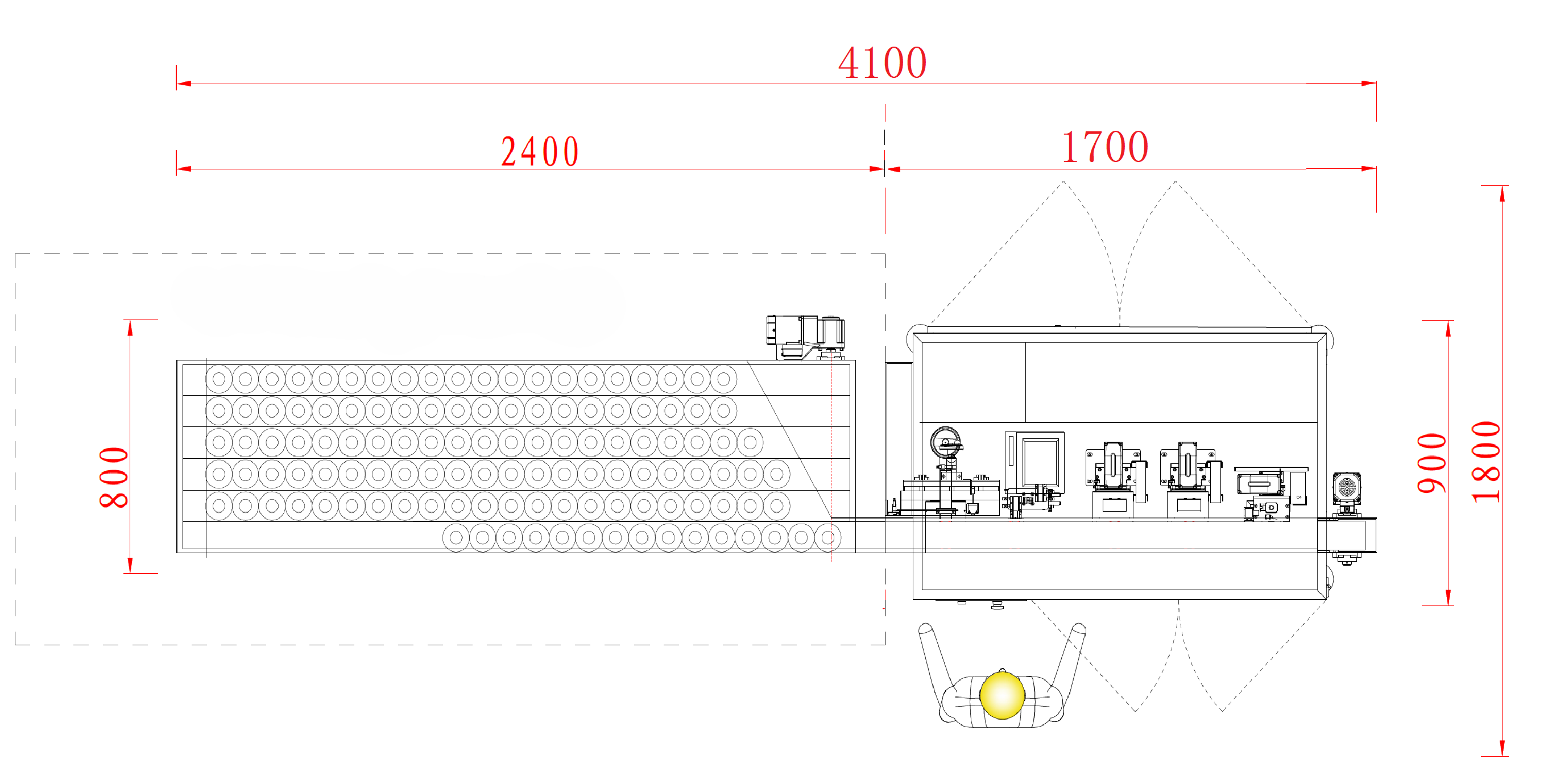

| Dimensions |

Main Unit (L × W × H): 1900 × 900 × 1900 mm |

| Full System :(L×W×H)=4000X900X1900 | |

| Weight | Approx.400KG |