Description

Applications

The CanNeed-ABMS-1100 is a fully automated, unattended can end size comprehensive tester. It employs a contact measurement method to automatically measure the can body height, dome depth, can end inner diameter, and flange width of two-piece cans. This enables continuous, high-efficiency automated testing of samples and serves as a standard instrument in the can-making industry.

Measurement Process:

1.Optional single or multi-channel automatic feeding device automatically transports sample cans to the inspection area.

2.An intelligent robotic arm picks up the sample can and places it in the measurement station, where it rotates automatically during measurement.

3.Multiple precision sensors controlled by pneumatic systems simultaneously inspect the sample can. The number of measurement points per rotation can be set from 1 to 50.

4.Measurement results are automatically saved and transmitted to the SPC system.

Advantages and Performance:

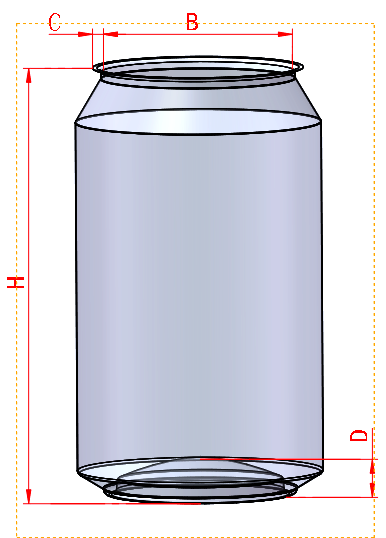

1.Multi-Point Automatic Measurement: Can body height (H), dome depth (D), can end inner diameter (B), and flange width (C).

|

B:can end inner diameter C:and flange width D:dome depth H:Can body height

|

2.Optional single-channel or multi-channel automatic feeding device allows testing of multiple can type samples in one run.

3.Single test station; simple replacement of positioning blocks accommodates samples with different can end inner diameters.

4.No need to change fixtures; adapts automatically to measure samples with body diameters of 202, 204, 209, and 211, and body heights ranging from 88 to 200 mm.

5.Fully automated measurement process saves time and labor costs while eliminating human error.

6.Customizable number of test points.

7.Automatic sorting of non-conforming samples, equipped with a dedicated channel for retaining rejects to facilitate user analysis.

8.Utilizes high-precision, world-class sensors for exceptional accuracy and repeatability.

9.Highly efficient, fast, and accurate measurement improves inspection throughput.

10.Separate electrical and mechanical compartment design for easy inspection and maintenance.

11.Tungsten carbide measuring tips ensure long-lasting durability.

12.Measurement results can be transmitted to an SPC system.

13.Upon completion of multiple sample measurements, users can review individual results, with automatic calculation of average, maximum, and minimum values.

Technical Specifications:

|

Resolution |

0.005mm |

|

Accuracy |

±0.02mm |

| Measurable Can Types |

Body Diameter:202、204、209、211 Can End Inner Diameter:200、202、206、209 Body Height:88-200mm |

|

Testing Speed |

120S/can(3 points per revolution) |

|

Sample Capacity |

Single-Channel Feeder: 12 samples |

|

Appearance |

Stainless Steel Enclosure |

| Operating Temperature | -20℃~50℃ |

| Air Supply |

4-6bar Dry Compressed Air |

|

Power Supply |

220V/50Hz |

| Dimensions |

L2700*W1000*H2000mm(with Feeder) |

| Weight |

260kg(with Feeder) |