|

| |

Product Classification : Can Making

|

|

SeamSight®-C Full Automatic Seam Monitor

|

|

The SeamSight® system is equipped with the new seam measuring software SeamSight® Professional Software. Which will do the line positioning automatically and the measurement to be finished within 1 second!

|

|

|

CanNeed-ACBT-1100 Automatic Buckle Tester Bottom for Can

|

|

CanNeed-ACBT-1100 is a full automatic buckle tester bottom for cans with unattended operation. It used to test the maximum pressure before can bottom starts to deform, and with dome growth function. CanNeed-ACBT-1100 is a standard instrument for can-making industry to achieve continuous and efficient automatic detection.

CanNeed-ACBT-1100 is equipped with auto sampling device which conveys the can to the testing area automatically. Swinging mechanical hand pushes the can to the testing station and it will measure and sort unqualified products automatically. It is also equipped with unqualified products samples retention channel, to facilitate users to analyze unqualified products.

|

|

|

CanNeed-AAXL-1100 Full Automatic Axial Load Tester

|

|

CanNeed-AAXL-1100 is a full automatic can axial load measure system with unattended operation. It can measure the axial load of the 2-piece can. It is a standard instrument for can-making industry which can realize the constant, efficient and automatic inspection for cans.

|

|

|

CanNeed-ADER-C-6000 Automatic Digital Enamel Rater for Cans

|

|

CanNeed-ADER-C-6000 is a fully automatic digital enamel rater with unattended operation. It¡¯s is used to measure the coverage, the compactness and the electric current value of the enamel coating inside the beverage cans. The contents will erode the metallic material and affect the quality and storage of products if the enamel coating inside the cans is not integrated.

The machine adopted fully automatic inspecting technology, more efficient and more effectively reducing the human errors. It is the standard for evaluating can quality in can-making industry.

|

|

|

CanNeed-CBT-500 Buckle Tester for Can Bottom (with dome growth measurement function)

|

|

CanNeed-CBT-500 Buckle Tester for Can Bottom determines the exact pressure at which the can bottom begins to buckle respectively the dome reverses. It¡¯s double stations and able to test both trimmed can and necked-in can without replacing the clamps and it¡¯s suitable for cans with different can plugs, body diameters and heights.

|

|

|

SeamSight®-VSM-6B Automatic Seam Monitor

|

SeamSight-VSM-6B Automatic Seam Monitor is a compact measuring system for quick and accurate automatically seam measurements, it has adopted the advanced optical system and Golden LensTM video capture device, which ensured the high image definition and the measurement accuracy.

SeamSight-VSM-6B Automatic Seam Monitor is equipped with the professional seam measuring software CanNeed-CND_VSM3.0. With the CanNeed SPC data collection system, the data of actual seam thickness, actual countersink, etc., can be transferred to the computer automatically.

|

|

|

CanNeed-ACTG-2000 Automatic Optical Coating Thickness Gauge (non-contact)

|

|

CanNeed-ACTG-2000 is a fully Automatic Optical Coating Thickness Gauge with unattended mode, it adopts non-contact optical measurement technology to measure the thickness and weight of dry film. It is a standard equipment in the canmaking industry to realize the continuous and efficient automatic inspection on the sample cans.

Compatible with straight-wall cans and finished cans. No changing parts are required for different can sizes in can heights and diameters.

|

|

|

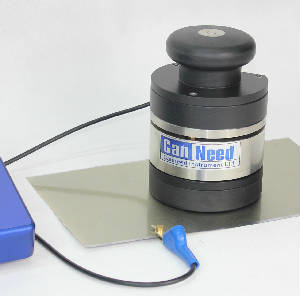

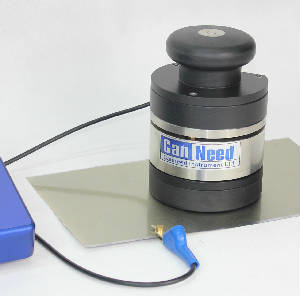

CMT-200 Mobility / Lubricity Tester for Cans

|

|

The CanNeed ¡°CMT-100 Mobility / Lubricity Tester for Cans¡± is for measuring the coefficient of sliding friction of can body and bottom. It can also measure the coefficient of sliding friction of blanks.

Install the corresponding clamp and place the sample on the clamp, then put the bob-weight unit on the sample. Pull the bob-weight and the indicator will display the coefficient of sliding friction.

|

|

|

CanNeed-AFMS-2000 Automatic Can Measure Desk for Front Stations

|

CanNeed-AFMS-2000 is a full automatic front end measure system with unattended operation. It can measure the wall thickness of upper and middle parts of the can, bottom depth and height of the can. It is a standard instrument for can-making industry which can realize the constant, efficient and automatic inspection for cans.

AFMS-2000 is equipped with auto sampling device which conveys the cans to the test area automatically. Swinging mechanical hand pushes the can to the test station then three-jaw centering mechanism locates the can quickly. Swinging device rotates the can to a defined angle to get various testing point. Test result is saved in database and is sent to SPC system automatically.

|

|

|

CanNeed-ACBT-1000 Automatic Buckle Tester Bottom for Can

|

CanNeed-ACBT-1000 Automatic Buckle Tester is a full automatic buckle tester bottom for cans with unattended operation.It determines the exact pressure at which the can bottom begins to buckle respectively the dome reverses with dome growth function. CanNeed-ACBT-1000 is a standard instrument for can-making industry which can respectively and efficiently finish auto online measurement.

CanNeed-ACBT-1000 is equipped with auto sampling device which conveys the can to the testing area automatically. Swinging mechanical hand pushes the can to the testing station and it will measure automatically. There is no need to change the clamps, applicable for empty necked-in cans and straight wall cans at the same time. There is no need to change the clamps, applicable to test the cans with different diameters and different heights at the same time. Testing results can be saved in database and automatically transferred to SPC system.

|

|

|

CanNeed-AAXL-2000 Automatic Axial Load Tester

|

CanNeed-AAXL-2000 is a full automatic can axial load measure system with unattended operation. It can measure the axial load of the 2-piece can. It is a standard instrument for can-making industry which can realize the constant, efficient and automatic inspection for cans.

CanNeed-AAXL-2000 is equipped with auto sampling device which conveys the can to the test area automatically. Intelligent mechanical arm puts the can on the test station and the top tray falls to reach the sample. When the force exceeds the can load limit, can deforms. Test curve will be showed on the screen. Mechanical arm will take the sample out after test. It is suitable for cans with different diameters of can mouth. Test result is saved in database and is sent to SPC system automatically.

|

|

|

CanNeed-CCAT-100 Can Comprehensive Abrasion Tester

|

It is used to evaluate the wear-resisting property for coating.

After well clamped the sample can,adjust testing pressure load,and set testing frequency and time,CCAT-100 will imitate the clashing of cans, wearing-resisting property can be evaluated by observing.

|

|

|

CSRT-100 Coating Scratch Resistance Tester

|

|

Under defined conditions, the CanNeed CSRT-100 is used to determine the resistance of a single coating or a multi-coating of paint, varnish or related product to penetration by scratching with a hemispherical tipped needle or abrasion tool and metal scratching tool and so on.

|

|

|

Seam-X-On-line X-Ray Automatic Seam Scanner(Non-destructive)

|

|

The CanNeed ¡°Seam-X-On-Line X-Ray Automatic Seam Scanner¡± adopts non-destructive measurement method to measure the seam quality, suitable for measuring the aluminum cans, steel cans , aluminum-iron composite cans and etc. It¡¯s applicable for online in producing department. It¡¯s a non-destructive, cost saving, accurate measurement and automatic equipment which can be installed on the production line to improve the sampling frequency.

Advantages:

01)Non-destructive measurement, avoid wasting samples

02)Non-destructive measurement, avoid environmental pollution and save handling charges

03)High sampling frequency, reduce the isolation inferior

04)High sampling frequency, cost saving

05)Can track the chucks corresponding to the unqualified products

06)360-degree fully scan measurement

07)Can be suitable for various types of cans

08)Higher accuracy

09)Avoid manual measurement error

10)Durable

11)Accord with the worldwide safety standards

|

|

|

Seam-X-On-line X-Ray Automatic Seam Scanner(Non-destructive)

|

|

The CanNeed ¡°Seam-X-On-Line X-Ray Automatic Seam Scanner¡± adopts non-destructive measurement method to measure the seam quality, suitable for measuring the aluminum cans, steel cans , aluminum-iron composite cans and etc. It¡¯s applicable for online in producing department. It¡¯s a non-destructive, cost saving, accurate measurement and automatic equipment which can be installed on the production line to improve the sampling frequency.

|

|

|

CTG-HP Hover Probe

|

|

The CanNeed CTG-HP Hover Probe is combined with CTG-300/CTG-310 Coating Thickness Gauge to test the lacquer film coating thickness and weight per unit area.

|

|

|

Seam-X-Line X-Ray Automatic Seam Scanner (Non-destructive)

|

The CanNeed Seam-X-Lab is suitable for laboratory.

Can open or close the door automatically£¬put in or take out the sample cans by manual operation.

The CanNeed Seam-X-Lab Automatic Seam Scanner adopts non-destructive measurement method to measure the seam quality, suitable for measuring the aluminum cans, steel cans , aluminum-iron composite cans and etc .It¡¯s a non-destructive, cost saving, accurate measurement and automatic equipment which can be installed on the production line to improve the sampling frequency.

|

|

|

CTG-300 Coating Thickness Gauge

|

|

The Canneed's "CTG-300 Coating Thickness Gauge", equipped with aerodynamic levitation measuring head, provides a computer enhanced method of rapidly assessing lacquer film weight of both internal and external coatings on beverage and food cans, and also tinplate.

The system provides the following benefits to the Can and End manufacturer:Reduced lacquer consumption, Greater product quality, Better operating efficiencies and Lower spoilage.

|

|

|

LaserScore-300 Automatic EOE Score Residue and Progression Measure System

|

The CanNeed LaserScore-300 Automatic EOE Score Residue and Progression Measure System (Non-contact)

Inspecting the thickness of End score residue and convex progression automatically

Based on laser technology and automatic visual positioning technology, Canneed¡¯s LaserScore-300 used to inspect EOE score residue and rivet convex progression automatically. LaserScore-300 has 2 work positions, each position adapts to inspect 202, 206 and 209 EOE.

|

|

|

Seam-X-Line X-Ray Automatic Seam Scanner (Non-destructive)

|

|

Seam-X-Line X-Ray Automatic Seam Scanner adopts non-destructive measurement method to measure the seam quality, suitable for measuring the aluminum cans, steel cans , aluminum-iron composite cans and etc .It¡¯s a non-destructive, cost saving, accurate measurement and automatic equipment which can be installed on the production line to improve the sampling frequency.

|

|

|

CMT-200 Mobility/ Lubricity Tester for Cans

|

|

The CanNeed ¡°CMT-200 Mobility / Lubricity Tester for Cans¡± is for measuring the coefficient of sliding friction of can body and bottom. It can also measure the coefficient of sliding friction of blanks.

Install the corresponding clamp and place the sample on the clamp, then put the bob-weight unit on the sample. Pull the bob-weight and the indicator will display the coefficient of sliding friction.

|

|

|

SeamSight®-B Full Automatic Seam System

|

|

The CanNeed Seam Sight® Full Automatic Seam Monitor has adopted the advanced optical system and Golden Lens® video capture device, which interference-free of external light source and ensured the high image definition and the measurement accuracy. The Seam Sight® system is equipped with the new seam measuring software Seam Sight®.

The CanNeed Seam Sight® -A system can automatically collect the data from STG-200-D Seam Thickness Gauge and CSG-200 Countersink Gauge. The actual seam thickness and countersink can be generated reports together with other data. To optimize the measurement process.

Measurement Process

Before cutting the sample can, use STG-200-D Seam Thickness Gauge to measure the seam thickness rate; meanwhile, use CSG-200 Countersink Gauge to measure the countersink rate; then the Seam Sight -A will collect the both data automatically.

After that, the sample can should be cut with CSS-1000 Anti-noise Seam Saw or CSS-2000 Seam Saw and placed at the camera position of the monitor. Then, the seaming images will be displayed on the screen. The auto measurement will be finished within 1 second if you press the ¡°Confirmation¡± button. All images and measurement data will be saved in the system data base.

|

|

|

CND-TRK-300 Oven Temperature Tracker

|

|

The ¡°CanNeed-TRK-300 Oven Temperature Tracker¡± is a professional oven temperature curve inspection system for the coating industry, it is including the data logger, heat insulation case, software (Chinese / English) and thermocouples.

"CanNeed-TRK-300 Oven Temperature Tracker¡± is use to pass through the oven with the solidifying products, and record down the real temperature during the process. The logger is in the centre of the system. Heat insulation case is for protecting the logger from over heat by the oven. When passing through the oven, the CanNeed-TRK-300 Oven Temperature Tracker will record down the real time temperature of the solidifying products through the 5 thermocouples which were connected to the products, and one thermocouple is for recording the air temperature of the oven. After the recording process was finished, use the CND_TRK Software to analyze the temperature data and generate the detail reports.

|

|

|

CSS 2000 Seam Saw

|

The CanNeed CSS-2000 Seam Saw is applicable for all types of cans of 45-260mm. The movable cutting platform is installed on the linear guide.

The CanNeed ¡°CSS-2000 Seam saw¡± is a special seam circular saw with double cut for double seam inspections. The CSS-2000 was specially designed for 2- and 3-piece cans.The nitrated blades achieve together with the speed of approx. 1.000 r/min. a very plain cut surface. The seam image on Caneed series Automatic Seam Computer (Video Seam Monitors), and automatic seam measuring systems gets thereby very clear and improves measurement speed and reliability.

|

|

|

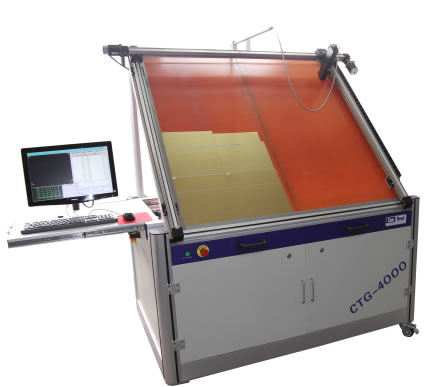

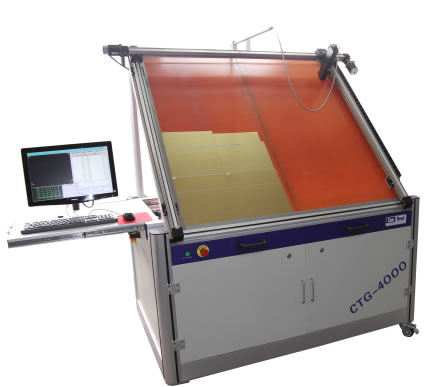

CTG-4000 Wet Film and Coating Thickness

|

Application:

1. Test wet film and coating thickness,both save time and improve quality

2. Test both single layer and multilayer coating

3. Adopt non-contact optical technique,suitable for research,quality control and on-line control.

4. Can be used in Solar energe,optical coating,foods package,metal package field.Improve the quality by appearance,adhesion,resistant to corrosion and fricton,as well as scratch.

|

|

|

SeamSight®-B Full Automatic Seam System

|

|

The CanNeed Seam Sight ® -B system can automatically collect the data from STG-200-d Seam Thickness Gauge and CSG-d Countersink Gauge. The actual seam thickness and countersink can be generated reports together with other data. To optimize the measurement process.

|

|

|

Seam-X-Lab Automatic Seam Scanner (Non-Destructive)

|

Seam-X-Lab Automatic Seam Scanner adopts non-destructive measurement method to measure the seam quality, suitable for measuring the aluminum can, steel can, aluminum-iron composite can etc.

It¡¯s a non-destructive, cost saving, accurate measurement and automatic equipment to improve the sampling frequency.

|

|

|

DER-400 Digital Enamel Rater

|

|

The CanNeed DER-400 Digital Enamel Rater is able to detect the exposed metal position more easily compare to the former models. The reformative electronic design makes it more sensitive, reliable and accurate. The anticorrosion characteristic of the enhanced can body support is ensured its durability. The film coated buttons are more durable and with better corrosion resistance.

|

|

|

SMM-300 Score Measure Microscope (PC Module)

|

|

The CanNeed "SMM-300 Score Measure Microscope" adopted the microscope technology to measure the score depth and residue of can ends. Equip with the high definition CCD camera system, locating done by displaying the clear groove bottom image of the end score on the screen, the measurement data is accurate, reliable and reproducible. The end sample to be clamped on a two-dimensional platen, which is much easier for locating and measurement. The fine digital indicator which has a resolution of 1µm (0.001mm).

|

|

|

CSS 2000 Seam Saw

|

|

The CanNeed "CSS-2000 Seam saw" is a special seam circular saw with double cut for double seam inspections. The CSS 2000 was specially designed for 2- and 3-piece cans. Also aerosol-cans may be sawed with this saw. The nitrated blades achieve together with the speed of approx. 1.000 r/min. a very plain cut surface. The seam image on Caneed series Automatic Seam Computer (Video Seam Monitors), and automatic seam measuring systems gets thereby very clear and improves measurement speed and reliability.

|

|

"If you can not find the product you need, please contact us or leave a message."

|

|