|

| |

Product Classification : All Products

|

|

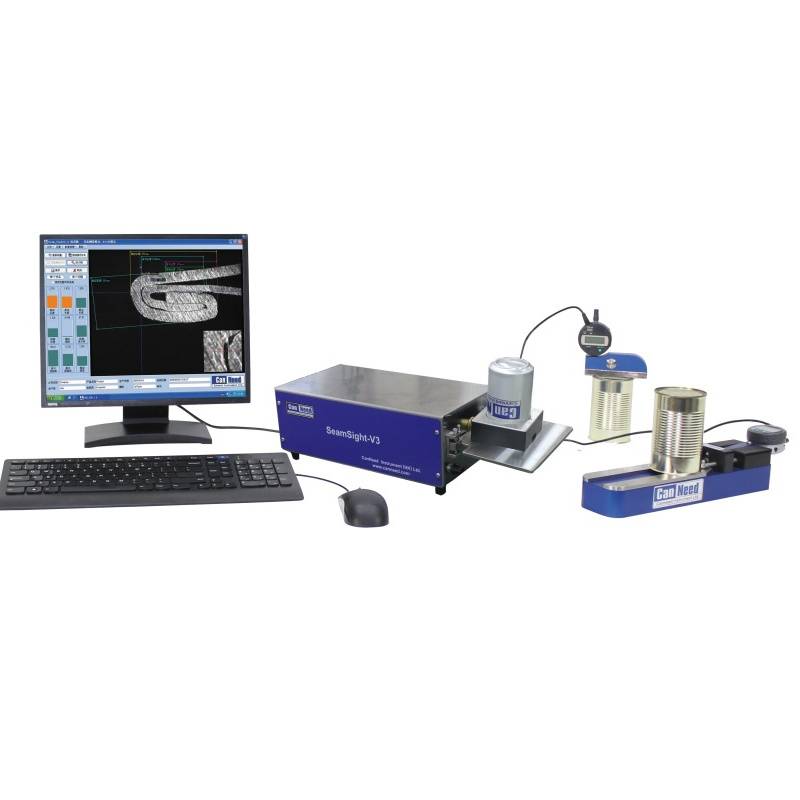

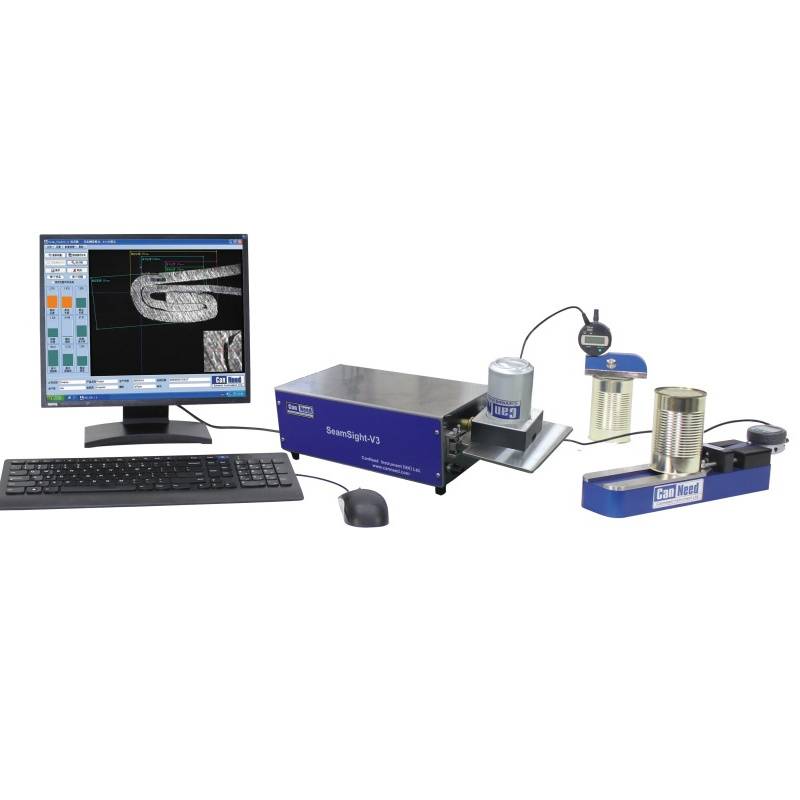

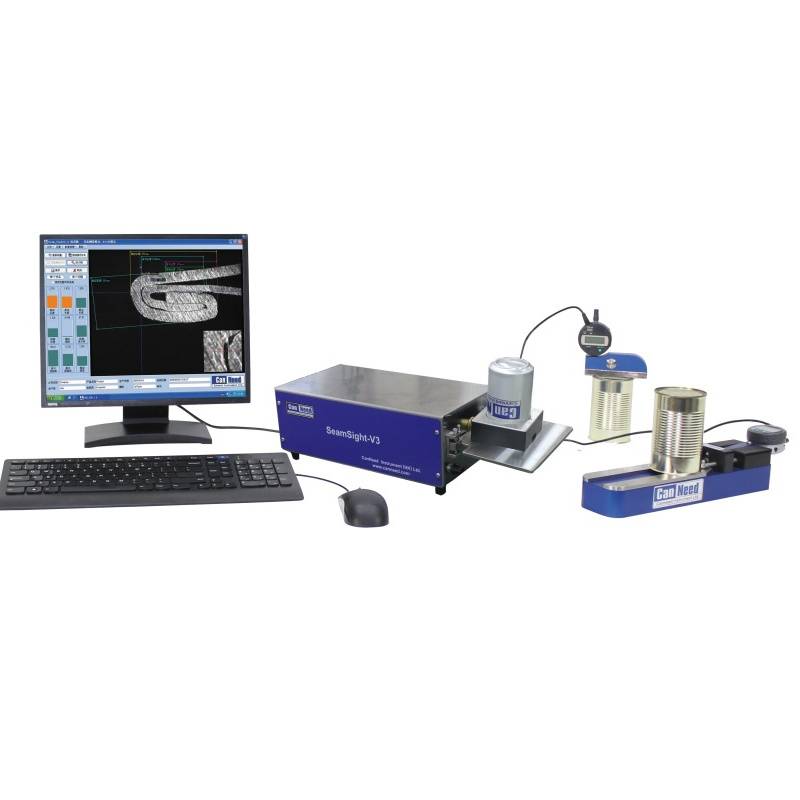

CanNeed SeamSight®-V3 Full Automatic Seam Monitor

|

|

The CanNeed Seam Sight® professional seam measuring software will do the line positioning automatically and the measurement to be finished within 1 second! The software also adopted the data base management system, all the measurement data will be restored in the system data base, so that to enhance the software performance and more convenience in data management. The result statistic and result chart has been added in the data base screen for overview and comparison. Meanwhile, the measurement screen has been optimized for a vivid result display.

The CanNeed Seam Sight® Full Automatic Seam Monitor has adopted the advanced optical system and Golden Lens® video capture device, which interference-free of external light source and ensured the high image definition and the measurement accuracy. The Seam Sight® system is equipped with the new seam measuring software Seam Sight® .

|

|

|

CanNeed-CAN-10774 Planer and Shaper Pin Height Gauge

|

|

CanNeed-CAN-10774 The Pin Height Gauge is commonly used in the initial setup of the seamer to ensure double seaming

performance and air removal.

All working surfaces are hardened and accurately ground.

|

|

|

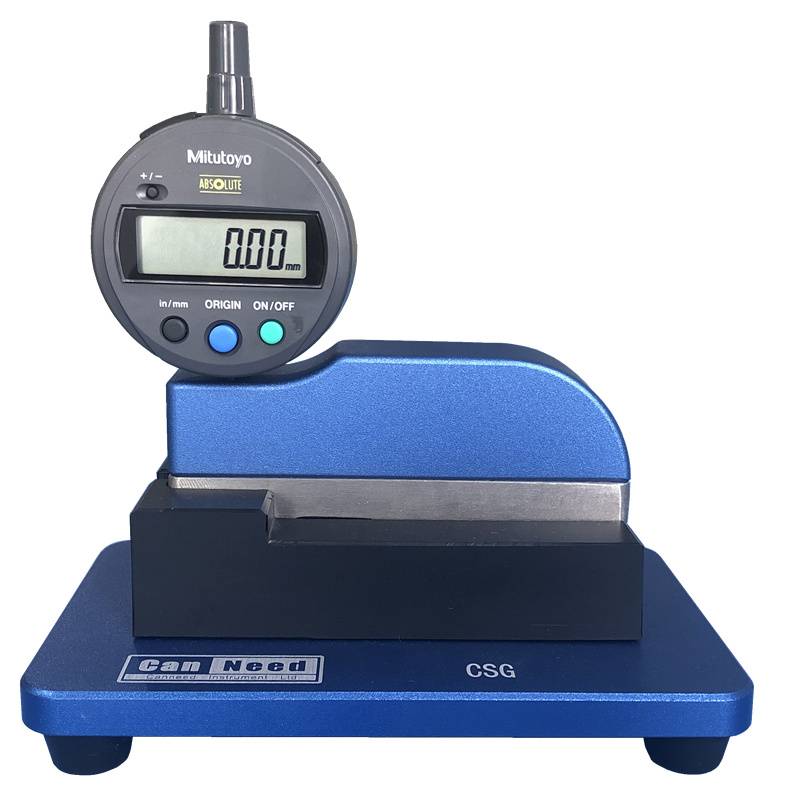

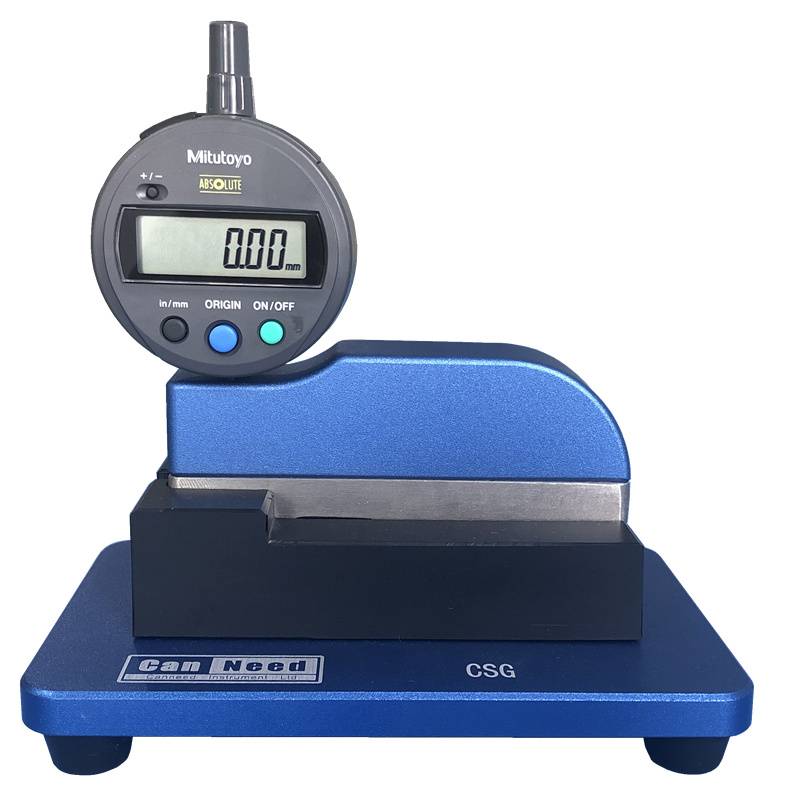

CanNeed-CSG-200 Countersink Gauge (Digital)

|

|

The CanNeed-CSG-200 Countersink Gauge (digital) is a Digital gauge for measuring Countersink depth parameters (the depth of beader of can). With the Mitutoyo 0.01mm Resolution Digital Indicator.

The gauge can be connected to a computer or SPC system via the adapter and cable, so that to avoid the manual recording and personal error. The gauge can also combine with Canneed Seam Monitors and import the measurement data into computer.

|

|

|

CAN-1050 Can Closing Force Gauge

|

"CAN-1050 Can Closing Force Gauge" is for measuring the force of seaming head of the seaming machine. Advantages:

1. Deduct the scrap rate of the production

2. Shorten the adjusting time, improved production efficiency.

3. Improved the seam quality

|

|

|

CanNeed-CND-TRK-300 Oven Temperature Tracker

|

|

The “CanNeed-TRK-300 Oven Temperature Tracker” is a professional oven temperature curve inspection system for the coating industry, it is including the data logger, heat insulation case, software (Chinese / English) and thermocouples.

"CanNeed-TRK-300 Oven Temperature Tracker” is use to pass through the oven with the solidifying products, and record down the real temperature during the process. The logger is in the centre of the system. Heat insulation case is for protecting the logger from over heat by the oven. When passing through the oven, the CanNeed-TRK-300 Oven Temperature Tracker will record down the real time temperature of the solidifying products through the 5 thermocouples which were connected to the products, and one thermocouple is for recording the air temperature of the oven. After the recording process was finished, use the CND_TRK Software to analyze the temperature data and generate the detail reports.

|

|

|

CanNeed-AS-100 AutoShaker Beverage CO2 Calculator

|

|

The “AS-100 AutoShaker Beverage CO2 Calculator” is a patented instrument which is for calculating the carbon dioxide content in the filled beverage in glass/PET bottles and cans. The simple operation which guarantees high reproducibility has led to its becoming a significant element of Quality Assurance in the drinks industry.

Attributes:

- Rotate by motor, avoid shaking by hand, guarantees high reproducibility

- With protection drum, more safety

- Measurement just need 3 minutes

- Simple operation

- Applicable to most common glass bottle PET bottle and cans.

|

|

|

CanNeed-AS-200d Digital AutoShaker Beverage CO2 Calculator

|

The “AS-200d Digital AutoShaker Beverage CO2 Calculator” is a patented instrument which is for calculating the carbon dioxide content in the filled drink in glass/PET bottles and cans. The simple operation which guarantees high reproducibility has led to its becoming a significant element of Quality Assurance in the drinks industry.

Attributes:

- Rotate by motor, avoid shaking by hand, guarantees high reproducibility

- With protection drum, more safety

- High accuracy, calculate the CO2 content automatically

- Good repeatability

- Simple operation

- Easy to calibrate

- Applicable to most common glass/PET bottle and cans.

|

|

|

CIDG Cap internal diameter Gauge

|

|

The “CIDG Cap Internal Diameter Gauge”is used to test the internal diamter of the crown caps to see if the gland is qualified or not.

|

|

|

PNR-E100 Pressure No Return Tester for Ends

|

|

The CanNeed "PNR-E100 Pressure No Return Tester for Ends" can measure the PNR value (Plastic Deformation) and the buckle value of the ends. During the whole pressurization process, use the micrometer to track and measure the deformation amount, generate the curve through the software and analyze the correlation between pressure and deformation amount of the ends.

|

|

|

SCO Sanitary Can Opener

|

A unique opener used to remove the centre section of the can end while keeping the double seam intact.

Sample can diameter: 40-300 mm 3-piece cans

|

|

|

CanNeed-L-100 CO2 Purity Tester

|

|

The “CanNeed-L-100 CO2 Purity Tester” adopts Alkali Absorption Method to measure the purity of CO2. It is widely used in gas monitoring station and brewery plants. CanNeed-L-100 is a CO2 purity tester with the highest accuracy of the world. Accuracy: 0.001%.

|

|

|

FWG-100-D, FWG-200-D, FWG-300-D Flange Width Gauge

|

|

The “CanNeed-FWG-100-d, CanNeed-FWG-200-d, CanNeed-FWG-300-d Flange Width Gauge (digital)” is used to measure the flange width of empty cans. Reliable design, invariableness measuring pressure and measuring angle which enable the inexperienced operators can also perform the measurement accurately. Auto aligning the center of can body, applicable for different types of cans.

If purchased the adapter and cable, the gauges can be connected to a computer or SPC system for data collection, avoiding the manual recording and personal error.

|

|

|

RPG-100 Roll profile Gauge

|

|

The CanNeed RPG-100 is able to scan profiles of seaming Rolls and Chucks (or other tooling - including carbide and ceramic tools) easily and quickly. The system can be used for acceptance testing for new seaming rolls or chucks, for quality assurance purposes and for stress analysis. Monitor tooling wear to replace rolls and chucks only when they need to be replaced

|

|

|

CanNeed-CAN-7001/7002 CO2 Tester and Pressure Tester

|

|

CanNeed-CAN-7001, CAN-7002 CO2 Tester and Pressure Tester is for measuring the CO2 content in carbonated beverages filled in glass and PET bottles or cans. It is designed according to ASBC Theory of American Society of Brewing Chemists, corresponding to “GB/T 4928 – 2001 Brewing Analysis Methods” and “GB/T 10792 – 1995 Carbonated Beverage Analysis Methods”. Therefore, the machine is widely used by Quality and Technical Supervision Bureau and beverage enterprises.

It is applicable to the bottles or cans with different sizes. After the sample is pierced, the pressure is read on the pressure gauge as soon as the equilibrium pressure is achieved. The CO2 content is determined by means of the CO2 slide rule or temperature/pressure relationship charts.

|

|

|

BDG-100 Bottom Depth Gauge

|

|

The CanNeed "BDG-100 Bottom Depth Gauge" is a Digital gauges for measuring Bottom depth parameters of beverage cans. Please indicate the can diameter when ordering.

|

|

|

CEBT-100 Buckle Tester for Can and End

|

The “Canneed CEBT-100 Buckle Tester for Can and end” determines the exact pressure at which the Can and End begins to buckle. With 4 measuring mode:

|

|

|

CanNeed-SM-24 Electric Belt Drive Seamer

|

The Canneed “SM- 24 Electric Belt Drive Seamer” (Desktop model) enables the users to do more lab tests. Such as, adjusting some technique, enhancing the products quality, test the empty cans and free ends, to insert a temperature logger into a can before running a temperature monitoring.

It is much more convenient for those lab tests, fast, easy and high efficiency.

|

|

|

CanNeed-CLT-100 Leak Tester for can

|

|

The “CanNeed-CLT-100 Leak Tester for can “ is used for checking the leakage of 3-piece cans in a water bath. It can test one can in each test.

The test procedure is performed semi-automatically and the CanNeed-CLT-100 is suitable for different sizes of round 3-piece cans.

Testing method: Place the sample can to the platen, the can will be fixed by the magnet disc plate, clampthe can to seal the top, then submerge the can into water and apply pressure to the can.

Observer the can body to see whether there are bubbles come out, if bubbles come out from the can body constantly, that means the sample can leaks. During the testing, operator is able to turn the sample over for easy observing the can top, can bottom, can body and welding line.

|

|

|

SST-2 Secure seal tester

|

|

The "canneed SST-2 Secure Seal Tester" is used to

test seal integrity on the glass or plastic containers and cans.

The SST-2 has been designed to address the special needs

of sealing cans and bottles that use aluminum roll-on,

twist crowns, or plastic caps.

The SST-2 operates with compressed air, nitrogen,

or carbon dioxide. By detecting gas leakage, rather than liquid,

the Secure Seal Tester gives more sensitive, accurate readings.

|

|

|

CanNeed-STR-100A Seam Stripper

|

The automatic “CanNeed-STR-100 Seam Stripper” is a sensible, affordable, teardown method to prepare the double seam teardown analysis. One fast, safe teardown operation without damaging or distorting the cover hook. Reduce teardown time for more frequent inspections. Tooling quick change in few seconds. Models are available for most common can sizes of beverage and food cans. When ordering, the end diameter and can height must be specified so that the appropriate change parts are included. Efficient cut and strip both aluminium and steel cans in a single motion. 10 seconds per can. Eliminates the repetitious actions by hand.

An important part of any seam evaluation is the actual teardown of the can seam to determine tightness or wrinkled rating.

|

|

|

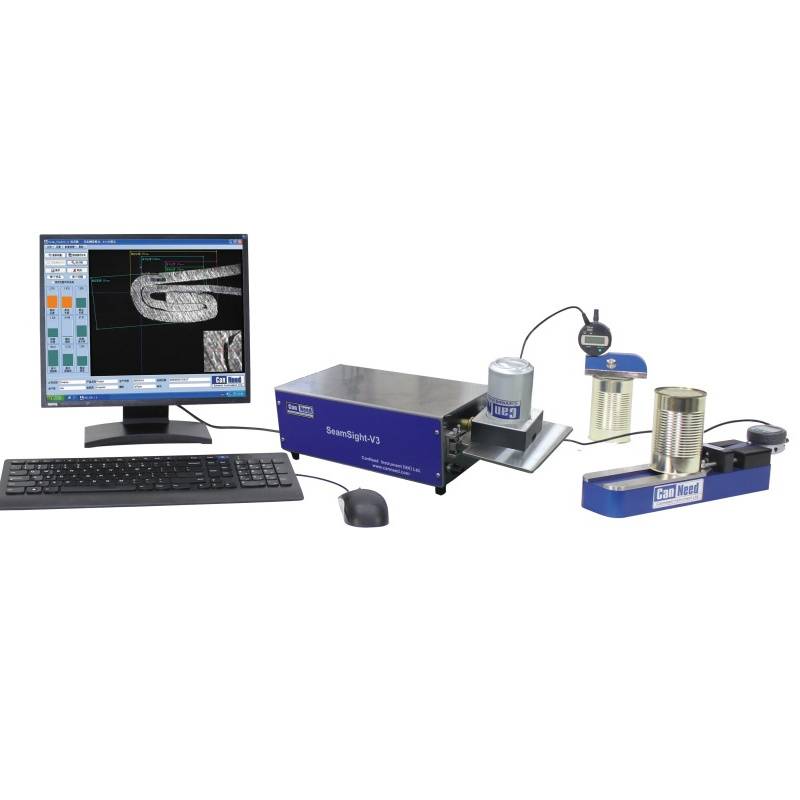

SeamSight®-V3 Full Automatic Seam Monitor

|

|

The CanNeed Seam Sight® professional seam measuring software will do the line positioning automatically and the measurement to be finished within 1 second! The software also adopted the data base management system, all the measurement data will be restored in the system data base, so that to enhance the software performance and more convenience in data management. The result statistic and result chart has been added in the data base screen for overview and comparison. Meanwhile, the measurement screen has been optimized for a vivid result display.

The CanNeed Seam Sight® Full Automatic Seam Monitor has adopted the advanced optical system and Golden Lens® video capture device, which interference-free of external light source and ensured the high image definition and the measurement accuracy. The Seam Sight® system is equipped with the new seam measuring software Seam Sight® .

|

|

|

MB-8A+ Auto Mashing Device

|

|

The CanNeed “MB-8A+ Auto Mashing Device” is the best choice for beer and malt Laboratory.

Attributes:

1. 8 orifices (optional for 4 / 8 / 16 orifices)

2. Auto water-in

3. LCD monitor, display the real time temperature and time, can switch to display the temperature curve.

4. Program controlled, accurately controls the temperature.

5. Mashing cup make from the thick wall stainless steel, smooth and weldless.

6. Inside material also stainless steel

7. Sink cover is make from polishing stainless steel

8. During the mashing process, all temperature and time parameter to be displayed on the screen.

9. State-of-the-art components and technology

10. Very quiet when running

|

|

|

PCD Pressure Calibration Device

|

The “PCD Pressure Calibration Device” a dedicated precision instrument for calibrating pressure gauges and digital pressure sensors.

It is a universal applicable device for all kinds of pressure calibrations.

As the CO2 content determination depends on the measurement of both the equilibrium pressure and the temperature, an accurate and reliable measurement of the pressure is essential, to avoid errors in the measurement of the CO2 content.

|

|

|

CanNeed-AMG-300 Aerosol Measuring Gauge

|

|

The CanNeed AMG-300 Aerosol Measuring Gauge is a Convenient Gauge for Aerosol Cans, it can measures 6 characteristics in 1 compact Gauge. measures the following characteristics:

1) Can Height over all (E)

2) Can Height over the seams (D)

3) Can height between the seams (F)

4) Top Outside Diameter (K),

5) Top seam Outside Diameter

6) Bottom seam Outside Diameter

The CanNeed AMG-300 saves valuable time and table space. Combine five essential aerosol can gauges into one convenient measurement Gauge.

|

|

|

CanNeed-CSG-A Countersink Gauge for Aerosol Cans (digital)

|

|

CanNeed-CSG-A Countersink Gauge (digital) is a digital gauge for measuring countersink depth parameters of aerosol cans. Equipped with Zero-Adjusting calibration platform and protection piece.

If purchased the adapter and cable, the gauge can be connected to a computer or SPC system for data collection, avoiding that the persons record the data. It can also used together with the seam sight monitor and output the measuring data to the PC.

|

|

|

CanNeed-CAN-5001 CO2 Tester and Pressure Tester

|

|

The CanNeed-CAN-5001, CAN-5002 CO2 tester and Pressure Tester are for measuring the CO2 content in carbonated beverages filled in glass and PET bottles or cans. It is designed according to ASBC Theory of American Society of Brewing Chemists, corresponding to “GB/T 4928 – 2001 Brewing Analysis Methods” and “GB/T 10792 – 1995 Carbonated Beverage Analysis Methods”. Therefore, the machine is widely used by Quality and Technical Supervision Bureau and beverage enterprises.

|

|

|

CanNeed-CST-100 Can Seal Tester (Vacuum mode)

|

|

CanNeed-CST-100 Can Seal Tester (Vacuum mode) is for testing the secure seal of the 3-pc cans by applying the vacuum pressure to see whether the cans leak. It can test 1 (one) round can at each test.

Test method: Fill the sample can with water, cover the transparent platen on the open top, turn on the vacuum pump to generate the negative pressure, and then observe whether there are air bubbles on the can body, if the air bubbles come out continually, that means leakage occurred.

CanNeed-CST-100 is applicable for different can sizes. Please order different platens accordingly.

|

|

|

CanNeed-IDG-100/200/300 Can Internal Diameter Gauge

|

The “CanNeed-IDG-100 Internal Diameter of Can” is used to measure the internal diameter of small cans, such as 200, 202, 206, 209.

The “CanNeed-IDG-200 Internal Diameter of Can” is used to measure the internal diameter of larger cans. According to clients’ request, CanNeed-IDG-200 can be made to measure 2 to 3 different sizes of cans at the most at the same time. Note: The difference between the internal diameters of the two cans must be over 10mm.

When placing the order, please indicate the internal diameters of the cans, such as 202 neck-in cans, 206 neck-in cans.

With the Mitutoyo 0.01mm resolution digital indicator.

If purchased the adapter and cable, the gauge can be connected to a computer or SPC system for data collection.

|

|

|

ELT-100 Leak Tester for End

|

The "Canneed model ELT-100 Leak Tester for End "is used to determine the pressure at which ends buckle. This tester is also used to test for pin hole leaks in the tab score and rivet area.

The ELT-100 applies high pressure air to the product side of and end until the end fails. Leaking spots are made visible by revealing bubbles in the water bath. The failure of an end occurs either when the end buckles or when it starts leaking, leakage is generally caused by faulty scores or rivets.

|

|

|

ISD-3000 Piercing and Sampling Device

|

|

The “ISD-3000 Piercing and Sampling Device” is for sampling from the bottled or canned products. Place the beverage onto the base, press down the handle and the piercing will be done. Extend the piercing needle into the bottom of samples, under the pressure from the CO2 outside, the liquid will flow into the measuring instrument.

|

|

"If you can not find the product you need, please contact us or leave a message."

|

|