|

| |

Product Classification : Can Making

|

| Total page:8

Current page:1 Total records:221 |

First |

Previous |

Next |

Last

|

|

|

CanNeed-ACBT+AAXL-2000 Automatic Can Resistance Tester

|

|

CanNeed-AAXL-2000 is a full automatic can axial load measure system with unattended operation. It can measure the axial load of the 2-piece can. It is a standard instrument for can-making industry which can realize the constant, efficient and automatic inspection for cans.

CanNeed-ACBT-1000 is a full automatic buckle tester for can bottom with unattended operation.It determines the exact pressure at which the can bottom begins to buckle respectively the dome reverses with dome growth function.

|

|

|

CanNeed-AAXL-1100 Full Automatic Axial Load Tester

|

|

CanNeed-AAXL-1100 is a full automatic can axial load measure system with unattended operation. It can measure the axial load of the 2-piece can. It is a standard instrument for can-making industry which can realize the constant, efficient and automatic inspection for cans.

|

|

|

CanNeed-ACBT-1100 Automatic Buckle Tester Bottom for Can

|

|

CanNeed-ACBT-1100 is a full automatic buckle tester bottom for cans with unattended operation. It used to test the maximum pressure before can bottom starts to deform, and with dome growth function. CanNeed-ACBT-1100 is a standard instrument for can-making industry to achieve continuous and efficient automatic detection.

CanNeed-ACBT-1100 is equipped with auto sampling device which conveys the can to the testing area automatically. Swinging mechanical hand pushes the can to the testing station and it will measure and sort unqualified products automatically. It is also equipped with unqualified products samples retention channel, to facilitate users to analyze unqualified products.

|

|

|

SeamSight®-C Full Automatic Seam Monitor

|

|

The SeamSight® system is equipped with the new seam measuring software SeamSight® Professional Software. Which will do the line positioning automatically and the measurement to be finished within 1 second!

|

|

|

CanNeed-MDER-C2 Multi-station Digital Enamel Rater for Cans

|

|

CanNeed-MDER-C2 is used to measure the coverage, the compactness and the electric current value of the enamel coating inside the food and beverage cans. The contents will erode the metallic material and affect the quality and storage of products if the enamel coating inside the cans is not integrated. The machine adopted semi-automatic technology, more efficient and more effectively reducing the human errors. CanNeed-MDER-C2 is the standard of can making industry.

|

|

|

CanNeed-MBT-300 Hall Effect Thickness Gauge(Magnetic Bottle Thickness Gauge)

|

|

The “CanNeed-MBT-300 Hall Effect Thickness Gauge (Magnetic Bottle Thickness Gauge)” is a refined portable thickness gauge. It is used to measure the thickness of nonmagnetic material, such as plastic, glass, synthetics, aluminum and titanium, etc. The measurement accuracy is undistorted by the samples’ shapes.

CanNeed-MBT-300 is based on the theory of Hall Effect. For test, place the steel ball on one side of the sample and the probe on the other side. The Hall Effect sensor on the probe measures the distance from the probe tip to the steel ball. The calculator will display the real thickness readings.

|

|

|

CanNeed-ACTG-2000 Automatic Optical Coating Thickness Gauge (non-contact)

|

|

CanNeed-ACTG-2000 is a fully Automatic Optical Coating Thickness Gauge with unattended mode, it adopts non-contact optical measurement technology to measure the thickness and weight of dry film. It is a standard equipment in the canmaking industry to realize the continuous and efficient automatic inspection on the sample cans.

Compatible with straight-wall cans and finished cans. No changing parts are required for different can sizes in can heights and diameters.

|

|

|

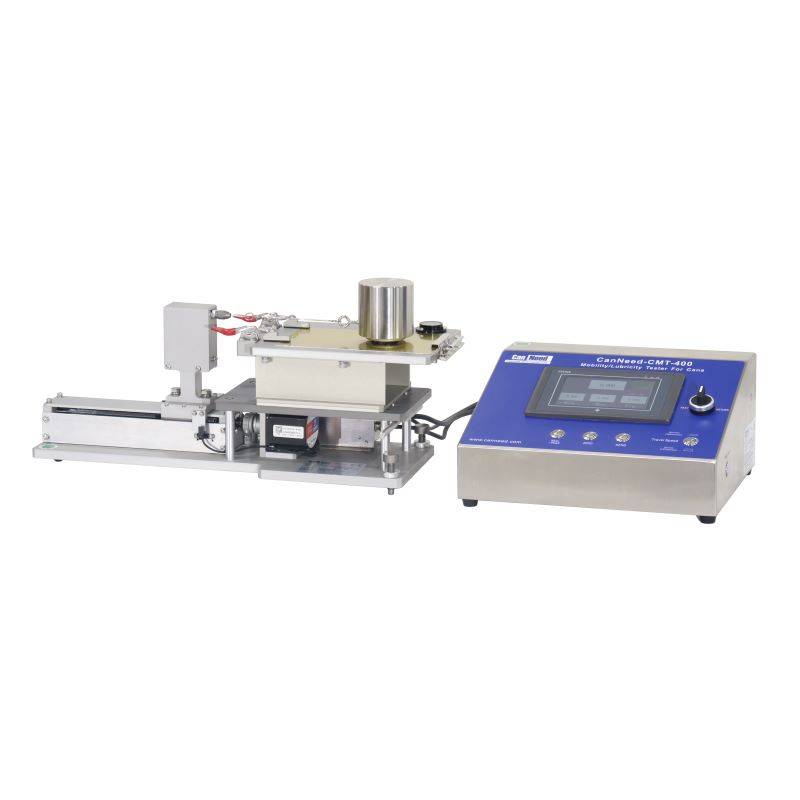

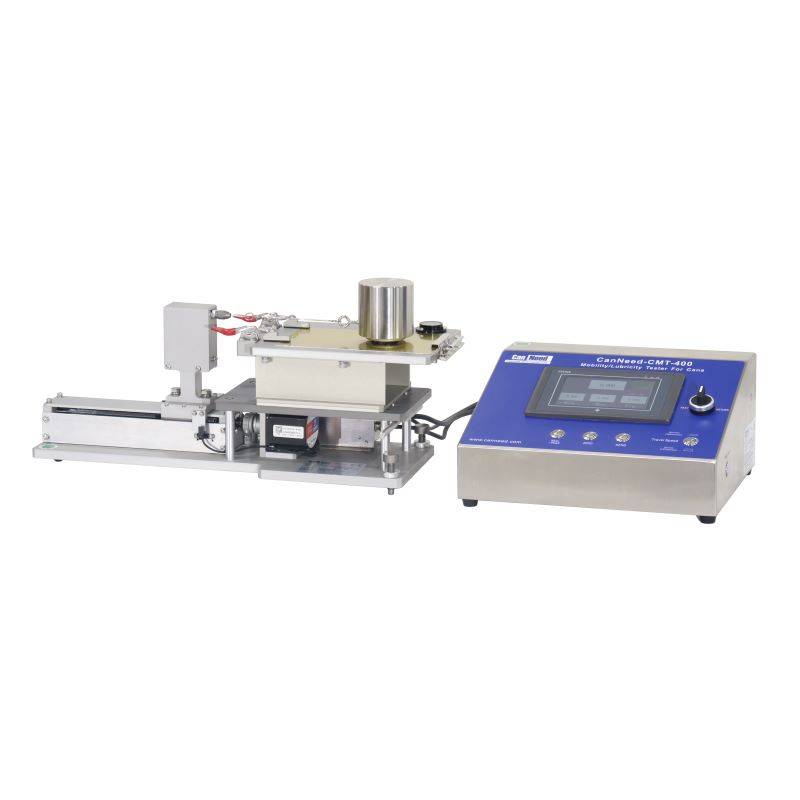

CanNeed-CMT-400 Mobility / Lubricity Tester for Cans (Digital)

|

|

CanNeed-CMT-400 Mobility / Lubricity Tester for Cans is for measuring the coefficient of sliding friction of can body and bottom. It can also measure the coefficient of sliding friction of blanks.

|

|

|

CanNeed-AFMS+ABMS-2010 Automatic Front End and Back End Measure Systems

|

|

CanNeed-AFMS-2000 is a full automatic front end measure system with unattended operation. It can measure the wall thickness of upper and middle parts of the can, bottom depth and height of the can. It is a standard instrument for can-making industry which can realize the constant, efficient and automatic inspection for cans.

CanNeed-ABMS-2000 Automatic Can Measure System For Back End is used to measure Flange Width, Can Height & Internal Can Mouth Diameter of 2-pc can by unattended operation. It is a standard instrument for can-making industry which can realize the constant, efficient and automatic inspection for cans.

|

|

|

SeamSight-C Full Automatic Seam Monitor

|

|

The SeamSight® system is equipped with the new seam measuring software SeamSight® Professional Software. Which will do the line positioning automatically and the measurement to be finished within 1 second!

Use the CanNeed SPC data collection system, The actual seam thickness, actual countersink, etc., can be transferred to the computer automatically.

The software also adopted the data base management system, all the measurement data will be restored in the system data base, so that to enhance the software performance and more convenience in data management. The result statistic and result chart has been added in the data base screen for overview and comparison. Meanwhile, the measurement screen has been optimized for a vivid result display.

With CanNeed Automatic Seam Sight® Monitor, press only one key “Auto Measure” to do the line positioning automatically and the measurement to be finished within 1 second! It can measure the seam dimension automatically, efficiently, simply and also avoid operator mistake. Use the CanNeed SPC data collection system (CSG-200 countersink gauge & STG-200D seam thickness gauge), the actual seam thickness, actual countersink, etc., can be transferred to the computer automatically. Such data can generate a report together with other data, improving the process.

|

|

|

CanNeed-ADER-C6000 Automatic Digital Enamel Rater for Cans

|

|

CanNeed-ADER-C6000 is a fully automatic digital enamel rater with unattended operation. It’s is used to measure the coverage, the compactness and the electric current value of the enamel coating inside the beverage cans. The contents will erode the metallic material and affect the quality and storage of products if the enamel coating inside the cans is not integrated.

The machine adopted fully automatic inspecting technology, more efficient and more effectively reducing the human errors. It is the standard for evaluating can quality in can-making industry.

|

|

|

Hallmag®-220 Hall Effect Thickness Gauge

|

Canneed-Hallmag-220 Hall Effect Thickness Gauge (Magnetic Bottle Thickness Gauge)” is a refined portable thickness gauge. It is used to measure the thickness of nonmagnetic material, such as plastic, glass, synthetics, aluminum and titanium, etc. The measurement accuracy is undistorted by the samples’ shapes.

Canneed-Hallmag-220 is based on the theory of Hall Effect. For test, place the steel ball on one side of the sample and the probe on the other side. The Hall Effect sensor on the probe measures the distance from the probe tip to the steel ball. The calculator will display the real thickness readings.

|

|

|

A-SeamSight-1000 Automatic Seam Monitor(Automatic Cutting and Measurement)

|

|

“A-SeamSight-1000 Automatic Seam Monitor(Automatic Cutting and Measurement)” is used to measure the seam quality of cans.

Automatic Seam Monitor(Automatic Cutting and Measurement)Equipped with Golden Lens® video capture device which interference-free of external light source and ensured the high image definition.

|

|

|

CanNeed-MDER-C2 Multi-station Digital Enamel Rater for Cans

|

|

CanNeed-MDER-C2 is used to measure the coverage, the compactness and the electric current value of the enamel coating inside the food and beverage cans. The contents will erode the metallic material and affect the quality and storage of products if the enamel coating inside the cans is not integrated. The machine adopted semi-automatic technology, more efficient and more effectively reducing the human errors. CanNeed-MDER-C2 is the standard of can making industry.

|

|

|

CanNeed-ADER-C3100 Automatic Digital Enamel Rater for Cans

|

|

CanNeed-ADER-C3100 is a fully automatic digital enamel rater with unattended operation. It’s is used to measure the coverage, the compactness and the electric current value of the enamel coating inside the beverage cans. The contents will erode the metallic material and affect the quality and storage of products if the enamel coating inside the cans is not integrated. The machine adopted fully automaticinspecting technology, more efficient and more effectively reducing the human errors. It is the standard for evaluating can quality in can-making industry.

|

|

|

CanNeed-CHG-200 Digital Can Height Gauge

|

|

CanNeed-CHG-200 Digital Can Height Gauge can quick measure the heights of cans, applicable for 2-pc cans, 3-pc cans and aerosol cans.

If purchased the adapter and cable, the gauge can be connected to a computer or SPC system for data collection.

|

|

|

CanNeed-ABMS-2000 Automatic Back End Measure System

|

CanNeed-ABMS-1000 Automatic Can Measure System for Back End is used to measure Flange Width, Can Height & Internal Can Mouth Diameter of 2-pc can by unattended operation. It is a standard instrument for can-making industry which can realize the constant, efficient and automatic inspection for cans.

The samples will be rotated automatically when measurement starts. The 3 pneumatic controlled sensors will measure the sample automatically. Up to 50 measuring points can be set in 1 circle. Measure results can be stored automatically by our software database, and transferred to SPC systems automatically. The instrument has been calibrated by standard gauge. And it’s applied to different can types and heights.

|

|

|

FWG-100-D, FWG-200-D, FWG-300-D Flange Width Gauge

|

|

The “CanNeed-FWG-100-d, CanNeed-FWG-200-d, CanNeed-FWG-300-d Flange Width Gauge (digital)” is used to measure the flange width of empty cans. Reliable design, invariableness measuring pressure and measuring angle which enable the inexperienced operators can also perform the measurement accurately. Auto aligning the center of can body, applicable for different types of cans.

If purchased the adapter and cable, the gauges can be connected to a computer or SPC system for data collection, avoiding the manual recording and personal error.

|

|

|

Hallmag®-300 Hall Effect Thickness Gauge

|

Canneed-Hallmag-300 Hall Effect Thickness Gauge (Magnetic Bottle Thickness Gauge)” is a refined portable thickness gauge. It is used to measure the thickness of nonmagnetic material, such as plastic, glass, synthetics, aluminum and titanium, etc. The measurement accuracy is undistorted by the samples’ shapes.

Canneed-Hallmag-300 is based on the theory of Hall Effect. For test, place the steel ball on one side of the sample and the probe on the other side. The Hall Effect sensor on the probe measures the distance from the probe tip to the steel ball. The calculator will display the real thickness readings.

|

|

|

CanNeed-CBT-400 Buckle Tester for Can Bottom

|

|

There is no need to replace the clamp when measuring necked-in cans and straight wall cans. CanNeed-CBT-400 can measure the cans with different diameters and heights.

Put the sample cans into the measuring station directly. There is no need to press the cans. It will automatically clamp and seal the cans by the cylinder and auto sealing device. When the operators press “TEST”, it will collect the buckle values of the cans.

|

|

|

CanNeed-TRK-6000S Oven Temperature Tracker

|

|

The CanNeed-TRK-6000 Oven Temperature Tracker is a professional oven temperature curve inspection system for the coating industry, it is including the data logger, heat insulation case, software (Chinese / English) and thermocouples.

|

|

|

CanNeed-CBT-CAL Calibration Cell For Buckle Tester

|

|

According to ISO and measuring management,users need to calibrate equipments at fixed period,but it is not convinient to send equipments to measuring organizations for calibration,then this CanNeed-CBT-CAL will help.

CanNeed-CBT-CAL is used to calibrate CanNeed-CBT-100/200/300, CanNeed-CBBT-100,CanNeed-CEBT-100, CanNeed-EBT-200/300

CanNeed-CBT-CAL display real time pressure,compare the value that displaying on CanNeed-CBT-100/200/300, CanNeed-CBBT-100, CanNeed-CEBT-100, CanNeed-EBT-200/300 to make the calibration.

|

|

|

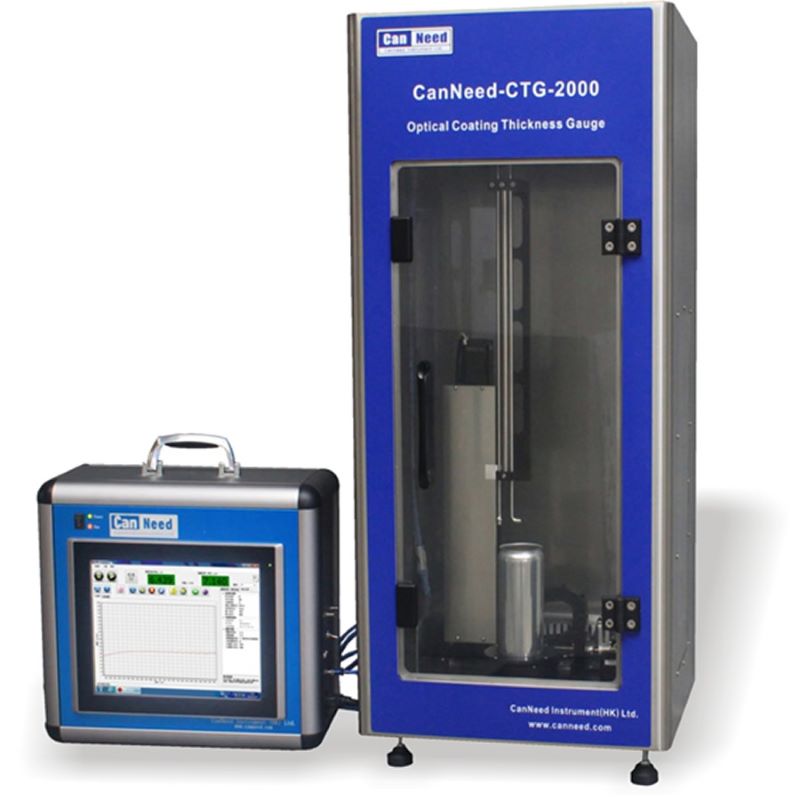

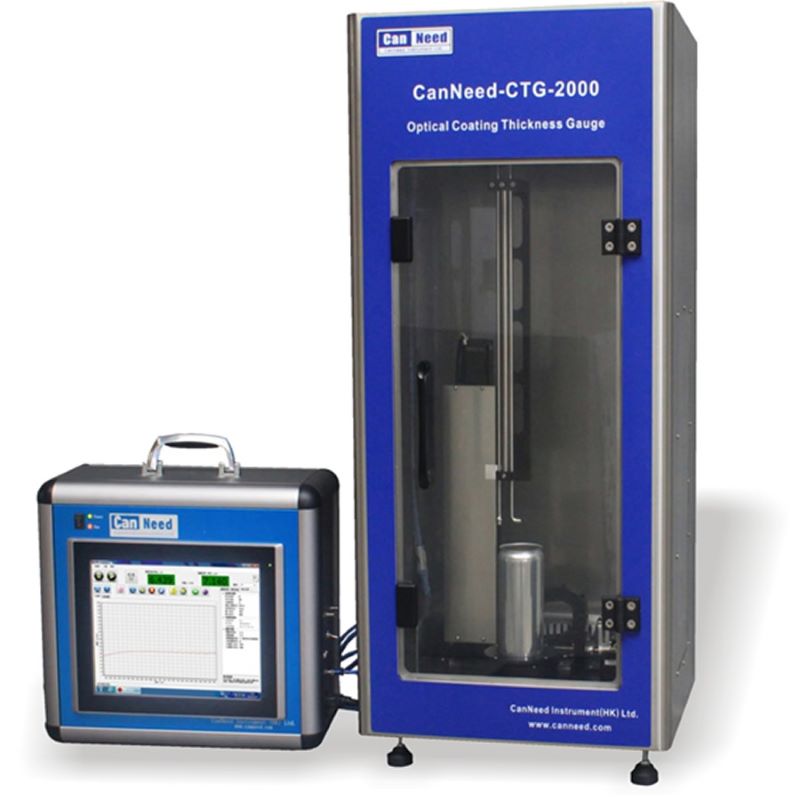

CanNeed-OCTG-2000 Coating Thickness Gauge

|

|

CanNeed-OCTG-2000 Coating Thickness Gauge is used to measure the coating thickness in real time, save time and improve the quality of the product. Non-contact optical measurement technology is applied to product development, laboratory quality control and online production control. In the solar energy industry, optical coating industry, food packaging,as well metal packaging, are very good choice to improve the surface quality of products: appearance, adhesion, corrosion resistance, abrasion resistance, scratch resistance.

|

|

|

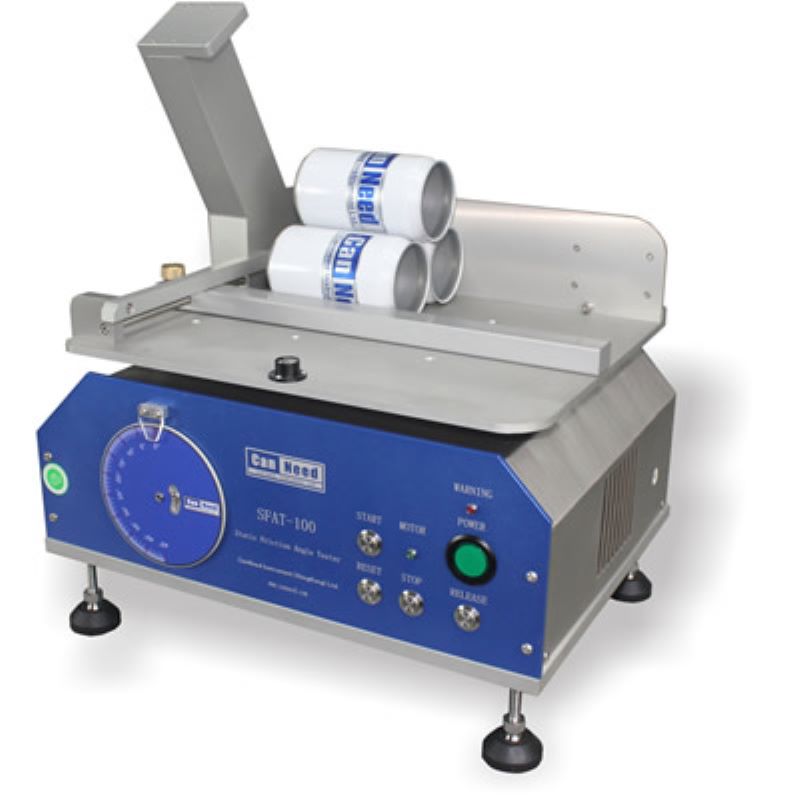

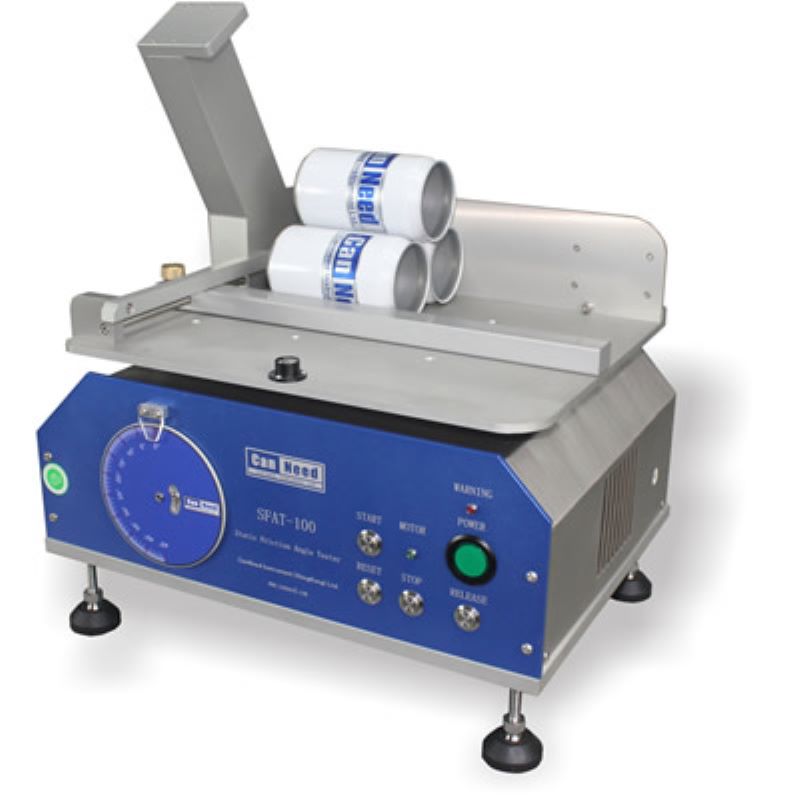

CanNeed-SFAT-100 Static Friction Angle Tester (Tilt Table)

|

|

CanNeed-SFAT-100 Static Friction Angle Tester enables accurate measurement of container lubricity and coefficient of static friction.

|

|

|

A-SeamSight-1000 Automatic Seam Monitor(Automatic Cutting and Measurement)

|

|

“A-SeamSight-1000 Automatic Seam Monitor(Automatic Cutting and Measurement)” is used to measure the seam quality of cans.

Automatic Seam Monitor(Automatic Cutting and Measurement)Equipped with Golden Lens® video capture device which interference-free of external light source and ensured the high image definition.

|

|

|

CanNeed-CSG-200S Countersink Gauge (with data output button)

|

|

The “CanNeed-CSG-200 Countersink Gauge (digital)” is a Digital gauge for measuring Countersink depth parameters (the depth of beader of can).

|

|

|

CanNeed-ADER-C6000 Automatic Digital Enamel Rater for Cans

|

|

CanNeed-ADER-C6000 is a fully automatic digital enamel rater with unattended operation. It’s is used to measure the coverage, the compactness and the electric current value of the enamel coating inside the beverage cans. The contents will erode the metallic material and affect the quality and storage of products if the enamel coating inside the cans is not integrated.

The machine adopted fully automatic inspecting technology, more efficient and more effectively reducing the human errors. It is the standard for evaluating can quality in can-making industry.

|

|

|

CanNeed-COG-100 Can Internal Size Gauge

|

|

CanNeed-COG-202 Can Internal Size Gauge is a digital gauge for quickly and accurately measuring the internal diameter and the flange width of empty cans.

CanNeed-COG-202 combines the advantages of Internal Diameter Gauge and Flange Width Gauge. If purchased the adapter of CanNeed-TRC-200 or CanNeed-TRC-400, it can auto calculate to achieve the actual internal diameter and avoid the measurement deviation caused by the “ellipse effect”. It can automatically position the middle line of the can body. The operators who lack experience can also measure accurately because of its reliable design and constant measuring pressure and angle. Equipped with the Mitutoyo 0.01mm Resolution Digital Indicator.

If purchased the adapter and cable, the gauge can be connected to a computer or SPC system for data collection.

|

|

|

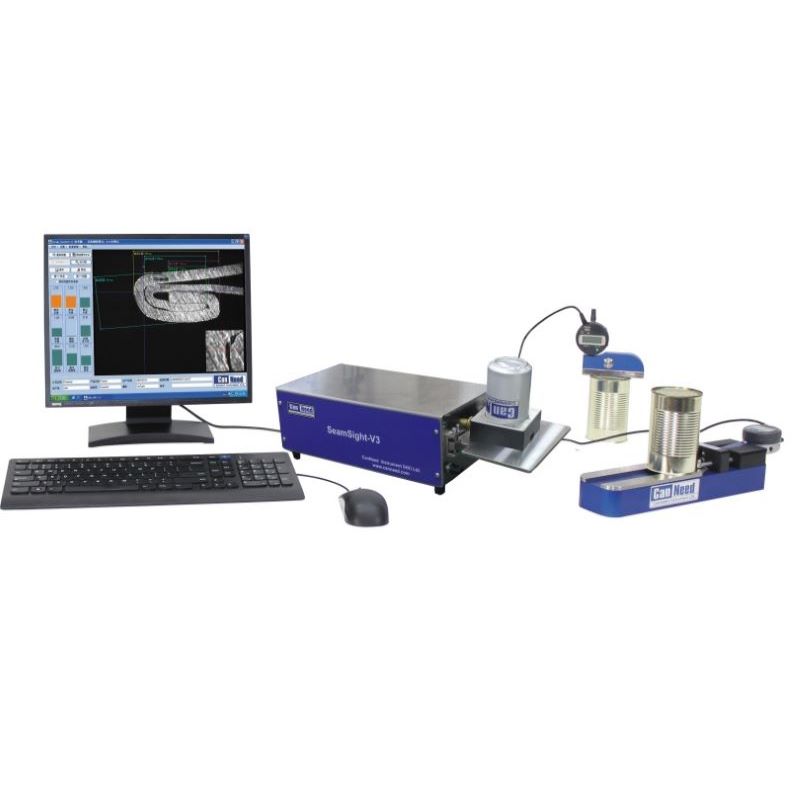

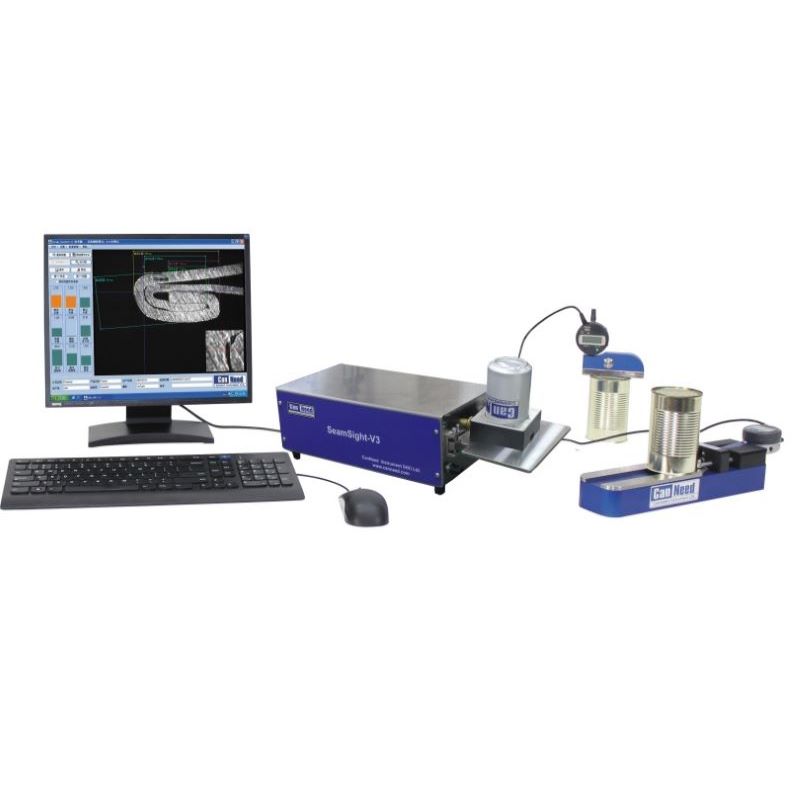

SeamSight®-V3 Full Automatic Seam Monitor

|

|

The CanNeed Seam Sight® professional seam measuring software will do the line positioning automatically and the measurement to be finished within 1 second! The software also adopted the data base management system, all the measurement data will be restored in the system data base, so that to enhance the software performance and more convenience in data management. The result statistic and result chart has been added in the data base screen for overview and comparison. Meanwhile, the measurement screen has been optimized for a vivid result display.

The CanNeed Seam Sight® Full Automatic Seam Monitor has adopted the advanced optical system and Golden Lens® video capture device, which interference-free of external light source and ensured the high image definition and the measurement accuracy. The Seam Sight® system is equipped with the new seam measuring software Seam Sight® .

|

|

|

CanNeed-RDG-100 Reform Dome Gauge

|

|

CanNeed-RDG-100 Reform Dome Gauge is used to measure the internal diameter(G) on the reform dome.

Such as 200, 202, 206, 209. Measuring dome integer inner diameter

Equipped with the Mitutoyo 0.01mm resolution digital indicator.

If purchased the adapter and cable, the gauge can be connected to a computer or SPC system for data collection.

|

|

| Total page:8

Current page:1 Total records:221 |

First |

Previous |

Next |

Last

|

|

"If you can not find the product you need, please contact us or leave a message."

|

|