Description

Applications

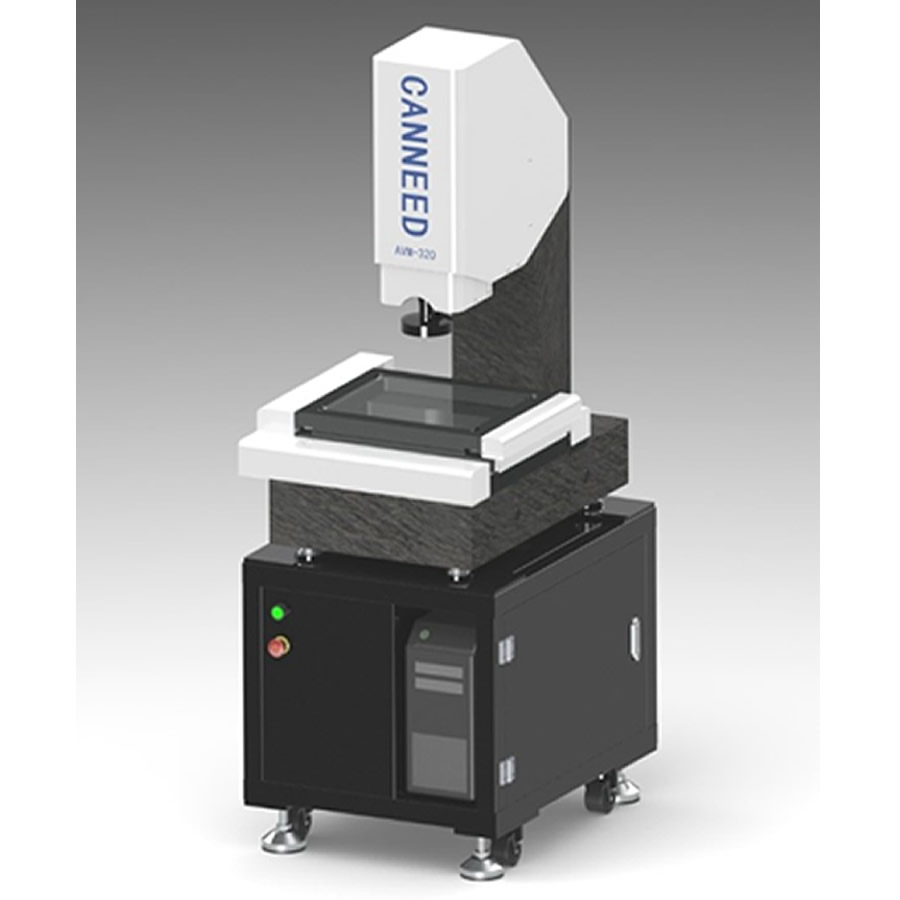

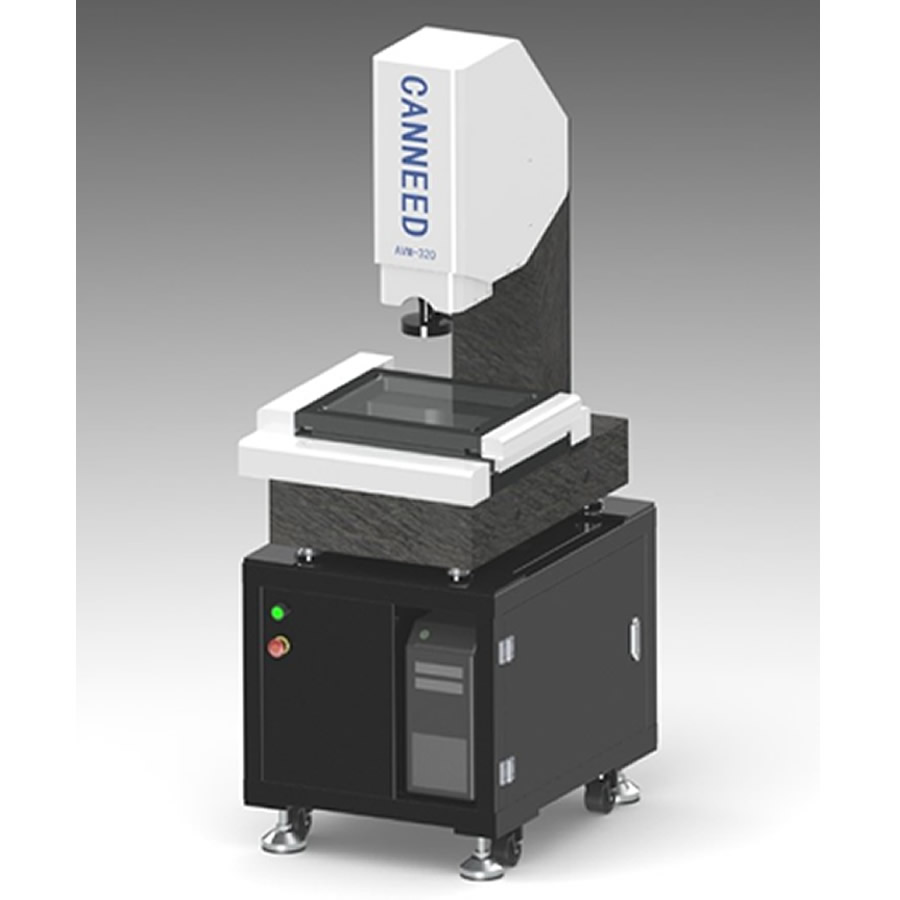

The Fully Automatic Vision Measuring System is an advanced inspection and measurement instrument that leverages machine vision, precision motion control, and AI technologies to perform automated image capture, automatic edge detection, measurement synthesis, and image stitching.

It is characterized by its high degree of intelligence and automation. This system liberates operators from tedious and repetitive tasks such as strenuous precise visual alignment, frequent point selection, repeated positioning movements, and constant function switching. Consequently, it increases batch inspection efficiency by hundreds of times, effectively meeting application needs ranging from production spot-checking to high-volume inspection.

|

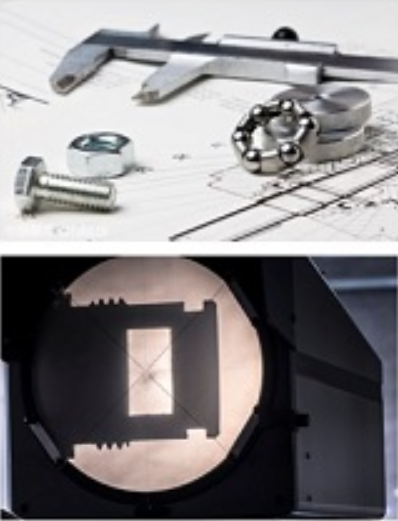

1. Demands highly skilled and experienced operators.

2. Difficult to ensure consistent and accurate probe placement. 3. Measurement results are operator-dependent and lack consistency. 4. Time-consuming process, unsuitable for high-volume batch inspection. 5. Prone to operator fatigue during prolonged measurement sessions. |

|

1. User-friendly operation

2. High precision and stability 3. Rapid and simple measurement 4. Powerful programming and automated measurement capabilities 5. Capable of measuring complex workpieces

|

Product Advantages & Superior Performance

1.Measures geometric elements including points, lines, arcs, circles, rectangles, ellipses, keyways, open curves, closed curves, planes, cylinders, cones, and spheres.

2.When equipped with height measurement modules such as a touch probe, laser sensor, or white light sensor on the Z-axis, it can also measure 3D geometric elements like cylinders, cones, spheres, heights, flatness, taper, and surfaces in three-dimensional space.

3.Capable of inspecting dimensions of features on the upper surface of objects, such as blind holes and grooves.

4.Measurement images and data can be exported and saved in various document formats for printing; also capable of generating SPC statistical analysis reports.

5.Graphics can be exported to AutoCAD; AutoCAD drawings can be imported into the software; user coordinates and measurement dimensions can be set at any time.

6.The lens magnification of the video measuring system can be adjusted from 28x to 225x.

Instrument Features

1.High-Precision Granite Construction: Utilizes a high-precision granite base and column, ensuring long-term stability and performance.

2.Stable Moving Worktable: Features a lightweight design with low inertia, ideal for high-speed motion measurement.

3.Three-Axis Servo Control: Provides high positioning accuracy and speed, enabling fully automatic measurement functionality.

4.Embedded Modular Control System: Integrates the complex control system within the instrument for higher stability.

5.High-Resolution Camera: Equipped with a 1.3-megapixel high-definition color camera with a 1/2-inch sensor area.

6.Optional Renishaw Simple Probe: Enables basic 3D measurement (optional accessory).

7.Optional Auto Zoom: Allows for highly efficient fully automatic measurement at multiple magnifications (optional accessory).

8.Proprietary Measurement Software: Features self-developed professional edition measurement software.

9.Advanced Software Capabilities: The software includes rapid auto-focus, automatic edge detection, powerful programming, and automated measurement functions.

10.Sub-Pixel Subdivision Technology: Enhances image boundary resolution for improved accuracy.

11.User-Friendly Software Interface: Mouse-operated software that is simple and easy to use.

12.Programmable Constant Current Surface LED Illumination: Adapts to the measurement of complex workpieces.

13Online SPC Data Processing & Analysis: Suitable for high-volume workpiece measurement tasks.

Technical Parameters

- Base Model AVM-320C Specifications

| Instrument Model: | AVM-320C | |

| Glass Stage Size | 380 × 310 mm | |

| Travel Range(mm) | X | 300 |

| Y | 200 | |

| Z | 200 | |

| Instrument Weight | 310 kg | |

| Overall Dimensions | 860 × 520 × 1160 mm | |

| Measuring Accuracy | X, Y-axis: (3 + L/100) μm

Z-axis: 5 μm |

|

| Scale Resolution | 0.5 μm | |

| Working Distance | 90 mm | |

| Control Mode | Fully Automatic | |

| Vision System | Camera | 1/2″ Color CCD |

| Zoom Lens Magnification | Manual Zoom: 0.7X – 4.5X | |

| Video Magnification | 28x – 225x | |

| Lighting System | Transmitted Light | White LED with continuously adjustable brightness |

| Surface Light | White LED with continuously adjustable brightness | |

| Power Supply | Input: 110-220V AC (±5%), 50/60 Hz

Grounding:Reliable instrument grounding required (grounding resistance < 5 ohms) |

|

| Optional Accessories | 1.Renishaw machine tool probe (UK)

2.Laser sensor 3.White light sensor 4.Other height measurement sensors |

|

- Auto-Zoom Lens Model: AVM-320D:

Based on the AVM-320C platform, the manual zoom lens (0.7X-4.5X) has been upgraded to a motorized auto-zoom lens with the same magnification range (0.7X-4.5X). This model is ideal for applications requiring frequent magnification changes during measurement processes.

Optional Accessories

1.Computer Desk

2.Height Measurement Modules:Machine Tool Probe、Laser Sensor、White Light Sensor

(Other height measurement modules available)