Description

1.Application

The CanNeed-ATPO-1100 Beer Fully Automatic Total Oxygen Analyzer is applicable for installation both beside the production line as a bypass system and within a laboratory setting. It enables rapid, real-time monitoring of total package oxygen (TPO) in finished beer, allowing the quality control center to grasp the actual TPO levels in packaged products in real time. It boasts powerful data analysis capabilities; the data statistical analysis system can assess the operational status of the filling machine’s valves based on the TPO data corresponding to each filling valve, determining whether they are in good condition or require maintenance.

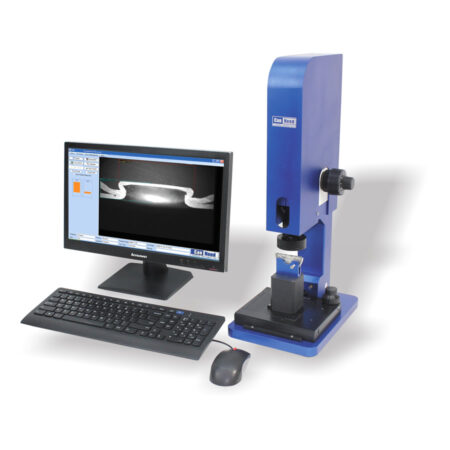

Measurement Items: Total Oxygen (TPO), Dissolved Oxygen (DO), Carbon Dioxide (CO2), Headspace Volume (HSO), Pressure, Temperature.When used in conjunction with a fixed-valve-number sampling system, the detection data can be correlated with the corresponding filling heads (valve numbers), thereby enabling efficient monitoring of the filling machine’s operational status.

2.Principle

Design Principle of the CanNeed-ATPO-1100 Beer Inline Total Oxygen Analyzer:

The system is designed to fully automate sample transportation, sample shaking pretreatment (for gas-liquid equilibrium), and the measurement of key beer parameters (Total Oxygen, Dissolved Oxygen, pressure, temperature, headspace volume, and CO2).

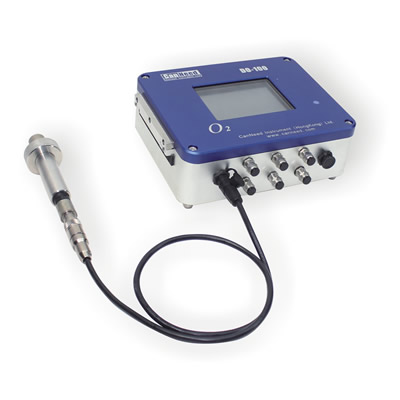

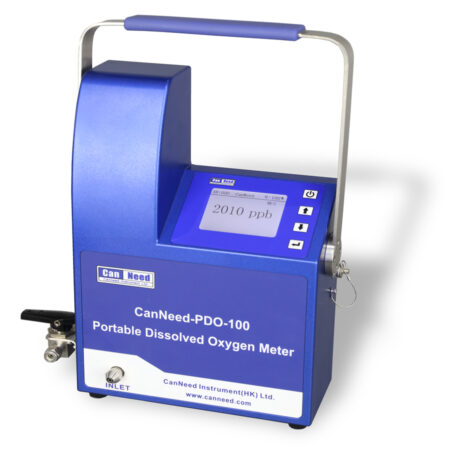

It utilizes a world-class advanced optical sensor based on the fluorescence quenching method, which offers fast response and high precision. The submersible probe design requires only a small sample volume to complete the multi-parameter measurement of beer.

3. Measurement Process

1) Place multiple beer samples onto the ATPO-1100’s automatic sample feeding conveyor belt.

2) Launch the software, initiate measurement, and the system will automatically feed samples, shake them, and measure parameters such as Total Oxygen and CO2.

3) All samples are measured automatically.

4) Measurement results are saved to the database.

5) The entire measurement process is completed automatically without the need for operator attendance.

4.Advantages and Performance

1) Automated Measurement: Fast and efficient operation.

2) Unattended Operation: Reduces labor costs.

3) Enhanced Accuracy: Eliminates human measurement errors.

4) High Speed and Frequency: Rapid testing at high frequency reduces the quantity of isolated defective products.

5) Process Evaluation: Provides crucial data for assessing the operational status of production process control points.

6) Data Integration: Measurement data can be automatically stored into an SPC (Statistical Process Control) system.

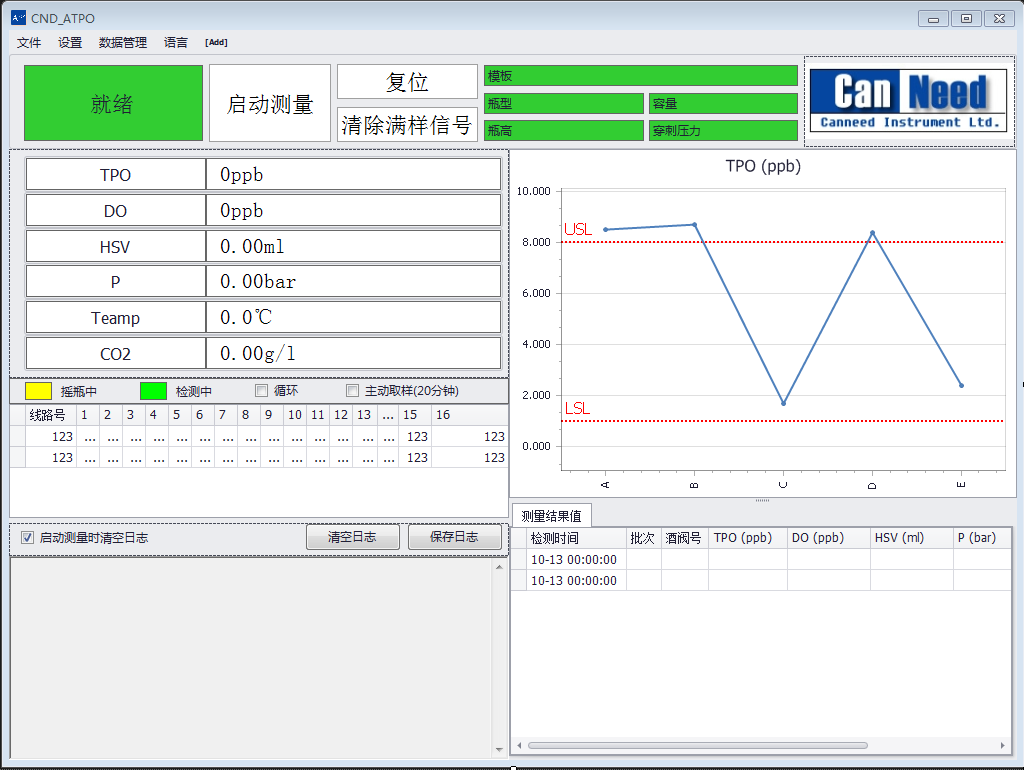

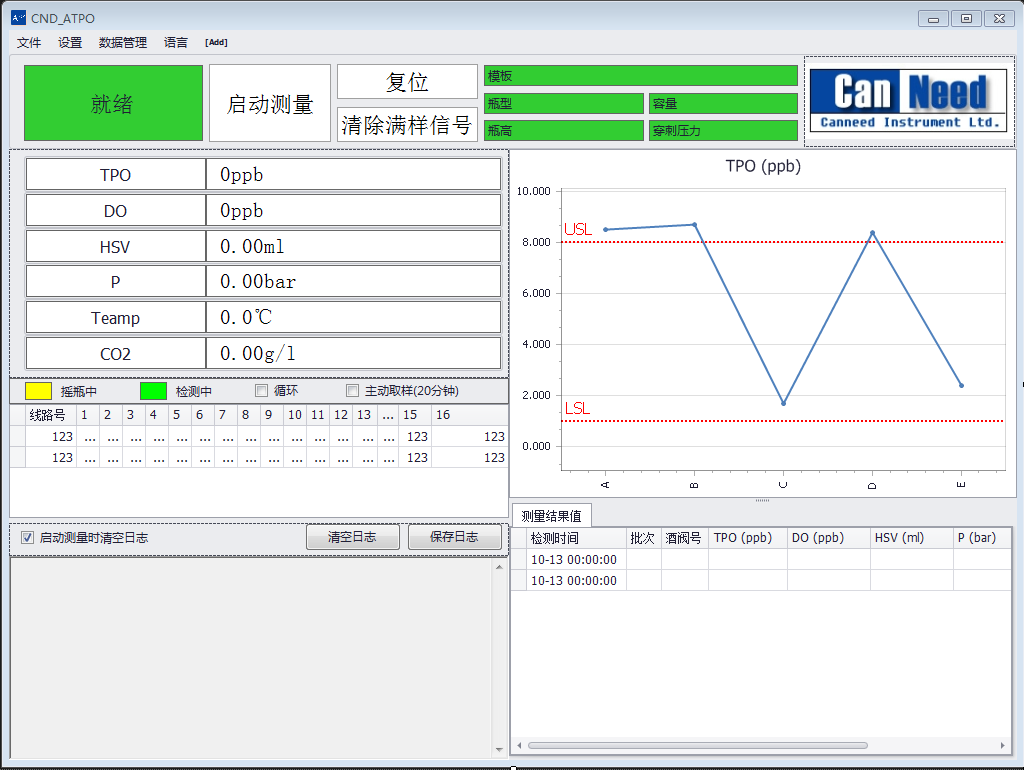

5.ATPO-1100 Software Features

1) Capable of establishing multiple sets of inspection qualification criteria. Each measurement can automatically determine whether the result is qualified and issue alerts.

2) Users can customize report formats to suit their company’s specific style and requirements.

3) Offers multiple statistical charts for convenient data analysis.

4) Measurement results can be saved to Excel spreadsheets.

6.Technical Specifications:

1) Installation Environment: Beside the production line or in a laboratory.

2) Required Conditions: Compressed air (>5 bar), high-purity nitrogen gas (N₂ >99.999%).

3) Power Supply: 110V/220V / 10A.

4) Ambient Temperature: 5-40°C.

5) Suitable Bottle Types: Bottles with crown caps or pull-tab caps, with a body diameter not exceeding 110mm and a height not exceeding 320mm. Special bottle types require evaluation.

6)Suitable Can Types: 300ml / 500ml (adaptable to various can types).

7)Cycle Time for TPO Measurement: Approximately 300 seconds per bottle (~5 minutes per bottle). The entire process, from bottle entry to exit, takes about 5 minutes.

|

Parameter Name

|

Measurement Range |

Resolution |

Accuracy |

Unit |

|

TPO

|

0 – 1000 ppb

|

0.1ppb |

±5ppb |

ppb

|

|

0 – 1000 ug/l

|

ug/l |

|

0 – 1.0 ppm

|

ppm |

| 0 – 1.0 mg/l |

mg/l |

|

DO

|

0 – 2000 ppb

|

0.1ppb

|

±5ppb

|

ppb

|

|

0 – 2000 ug/l

|

ug/l |

|

0 – 2.0 ppm

|

ppm |

|

0 – 2.0 mg/l

|

mg/l |

|

HSO

|

0-80ml |

0.01ml |

±2% |

ml

|

|

Temp

|

-5.0—40 ℃ |

0.1℃ |

±0.2℃ |

℃ |

| 23.0—104 ℉ |

℉ |

|

Pre

|

0.0—5.0 Bar |

0.01bar |

±0.02bar |

Bar |

| 0.0—72.5 Psi |

Psi |

|

CO2

|

2—15 g/l |

0.01Vol |

±0.02Vol |

g/l |

| 1—7.5 Vol |

Vol |

|

0.2-1.5 %B.W.

|

%B.W. |