Description

Applications:

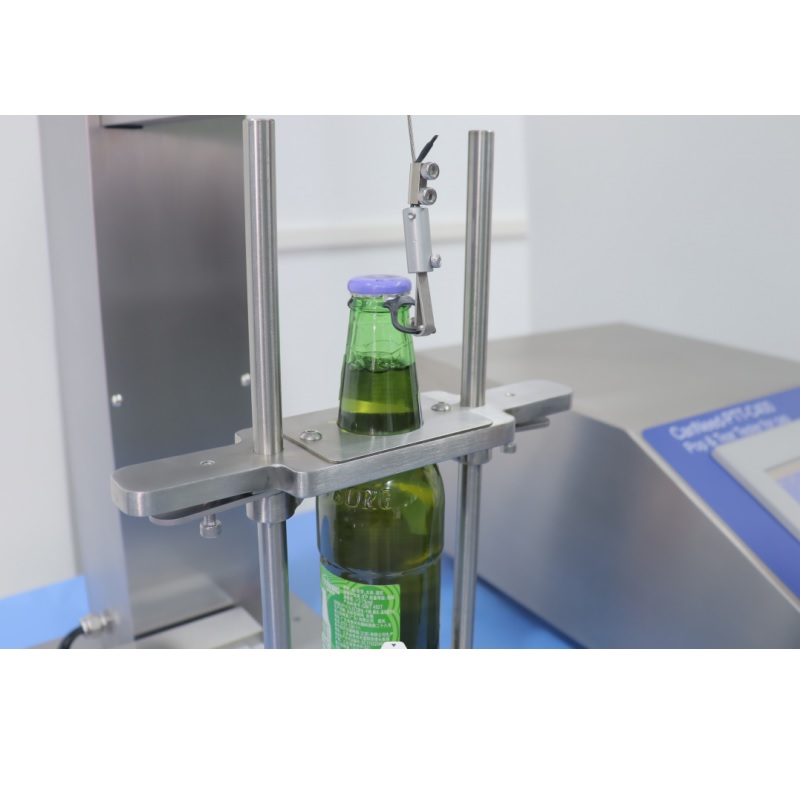

CanNeed-PTT-C400 is used to test the tensile force when opening and tearing the pull tab bottle cap, as well as the strength of the pull tab.

The instrument uses motor-driven measurement to ensure more precise test data. Data can be saved and viewed on a computer, and is applicable to samples of various heights.

Measurement Process:

- Hook the pull hook onto the pull tab of the bottle cap, and thread the steel wire through the guide wheel below;

- The tensile force system applies a uniform tensile force to the bottle cap, while the display shows the magnitude of the applied force;

- After the bottle cap breaks open, the module system applies a corresponding tensile force to the bottle cap tensile force system at a uniform rate, while the display shows the magnitude of the applied force. The test is completed once the bottle cap is torn open;

- Reset the instrument to its initial state and prepare for the next test.

Benefits:

- Two measurement modes: full-open mode and pull-ring strength mode;

- Equipped with a PLC touchscreen display control system for automatic data collection;

- Features a lifting platform to measure samples of various sizes;

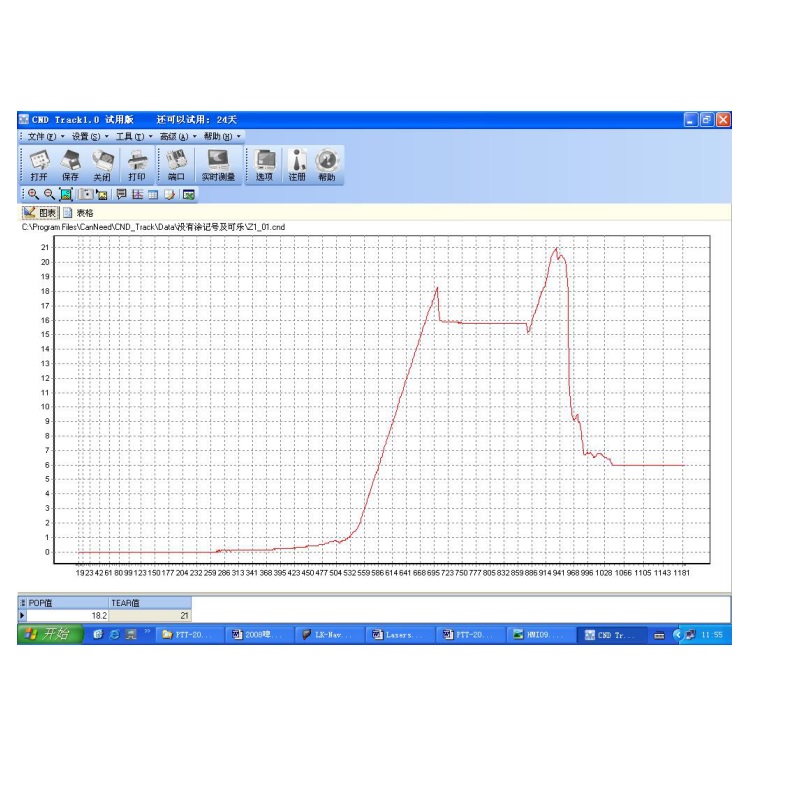

- Individual measurement results can be viewed, automatically calculates the average, maximum, and minimum values;

- Features RS232C data output functionality, database software for comprehensive data management;

- Constructed from oxidised aluminium and stainless steel materials, ensuring durability and longevity;

- High precision with calibration functionality, facilitating calibration without the need for an air source;

- Equipped with embedded mechanical testing control and analysis software to analyse the force curve throughout the entire testing process;

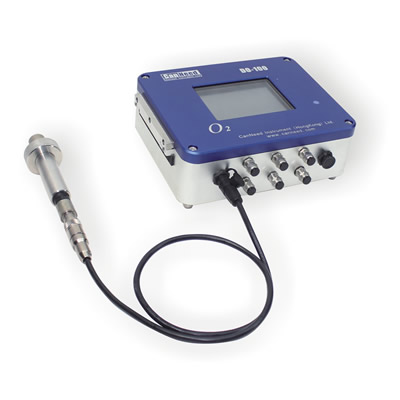

- Optional manual bottle cap sealing machine available for manual sealing of various wine bottles, soda bottles, etc.

Technical parameters:

| Measure range | 0-200N |

| Measurement sample | Maximum bottle height: 300 mm, maximum bottle diameter: φ98 mm(others by order) |

| Resolution | 0.01N |

| Accuracy | ±0.5% of full scale |

| Interfaces | RS232C |

| Units | N, kgf, lbf |

| Power supply

Dimensions |

AC220V

Test platform: L590*W250*H695mm, Control box: L330*W530*H240 |

| Weight | 30KG |