Beer, Beverages&Canmaking

Double Seam | Coating Quality | 2-piece can | Food Cans | Metal End/Lid | Canned Food | Beer&Beverages | Glass Bottle | PET Bottle&Preform | SPC SoftWare

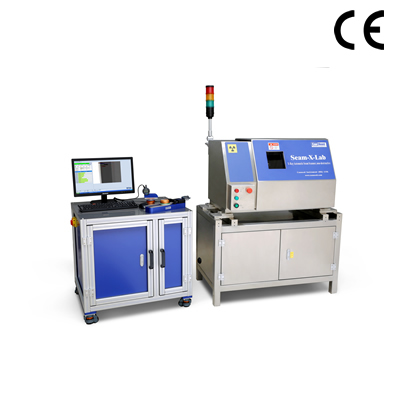

On-line Automatical Inspection

On-line inspection for food, beverage&packaging | Pharmaceuticals Inspection | On-line inspection for automobiles and parts | Cell phone and electronics industry

General Measuring Instrument

Electronic and Lithium Battery Testing Equipment

Electronic Component Counter | Profilometer | Lithium battery testing equipment

Spectrometer&Cell Phone Glass Cover Inspection

Machine Vision System

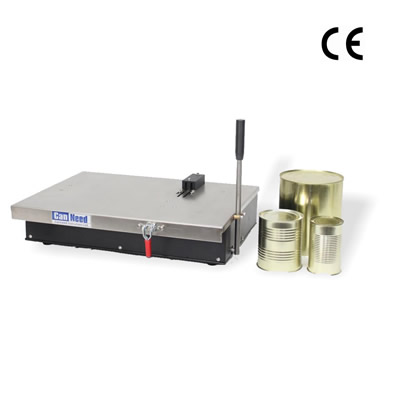

Beer and Beverage Industry

Food and Canning Industry

Canmaking industry

Glass Bottle Industry

PET Bottle and Embryo Industry

Pharmaceutical industry

Mobile Phone and Mobile Glass Cover

Electronics and Semiconductor Industry

Lithium Battery Industry

Automotive Parts Industry

Parts Processing Industry

Coatings industry